Types of Hydroponic Ebb and Flow: Varieties Explored!

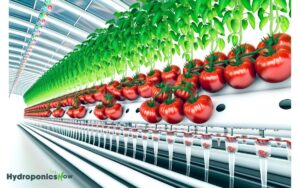

Hydroponic ebb and flow systems are diverse, each with unique attributes enhancing efficiency and crop yields.

Basic systems employ cyclic flooding and draining to optimize nutrient absorption. Modular systems offer scalable, customizable components for tailored solutions.

Multi-tier systems maximize space and increase plant density, boosting productivity by up to 30%. Vertical systems efficiently utilize vertical space, ideal for urban farming.

Automated systems leverage advanced sensors and controllers for precise nutrient management and irrigation, enhancing yields by up to 30%.

Exploring these variations provides further insight into optimizing hydroponic growth strategies.

Key Takeaways

Basic Ebb and Flow Systems

Utilizing a cyclic flooding and draining mechanism, basic ebb and flow systems, also known as flood and drain systems, facilitate efficient nutrient delivery and oxygenation to plant roots in hydroponic setups.

This method involves periodically flooding the grow tray with nutrient-rich solution, followed by a draining phase.

The periodic flooding guarantees that roots are adequately supplied with essential nutrients and water, while the draining phase allows for oxygen-rich air to re-enter the root zone, preventing hypoxia and promoting robust root development.

Evidence suggests that this system optimizes nutrient absorption and mitigates the risk of root diseases. The cyclic nature of this technique mimics natural hydrological cycles, thereby creating a stable environment for plant growth and enhancing overall yield efficiency.

Modular Ebb and Flow Systems

Modular ebb and flow systems offer a scalable and customizable approach to hydroponic cultivation. Growers can tailor the system components to specific crop requirements and space constraints.

These systems are characterized by their flexibility, enabling the integration of various grow trays, reservoirs, and pumps to create a highly efficient nutrient delivery method.

Each module can function independently or as part of a larger network, facilitating precise control over water and nutrient distribution.

Evidence suggests that modular systems enhance resource efficiency and crop yields by enabling targeted interventions and minimizing nutrient wastage.

Additionally, the modular design simplifies maintenance and expansion, providing an adaptable solution for both small-scale hobbyists and commercial operations seeking to optimize hydroponic productivity.

Multi-Tier Ebb and Flow Systems

Multi-tier ebb and flow systems, which involve stacking multiple layers of grow trays vertically, maximize space efficiency and enhance production capacity in hydroponic setups.

By leveraging vertical space, these systems provide a higher plant density per unit area, greatly boosting yield potential.

Each tier operates independently, allowing for tailored water and nutrient delivery specific to the plant type and growth stage.

Critical design considerations include ensuring adequate light penetration and airflow to all levels, which mitigates the risk of mold and promotes uniform plant development.

Research indicates that multi-tier configurations can increase productivity by up to 30% compared to single-tier systems, making them ideal for commercial operations aiming to optimize resource use and maximize output.

Vertical Ebb and Flow Systems

Vertical ebb and flow systems are characterized by their stacked, columnar arrangement of grow trays. They offer an advanced solution for optimizing spatial efficiency and resource management in hydroponic agriculture.

These systems maximize vertical space, making them ideal for urban farming and indoor cultivation settings.

Key advantages include:

- Space Utilization: By utilizing vertical space, these systems greatly increase the number of plants that can be cultivated per square meter, essential for high-density urban environments.

- Resource Efficiency: The cyclical nature of ebb and flow guarantees efficient nutrient delivery and water conservation, reducing waste and operational costs.

- Scalability: Modular design facilitates easy expansion and customization, enabling growers to scale operations according to demand and capacity.

Empirical studies support their efficacy in enhancing yield and sustainability.

Automated Ebb and Flow Systems

Automated ebb and flow systems, leveraging advanced sensors and controllers, offer precise management of nutrient delivery and water cycling, thereby optimizing plant growth and minimizing manual intervention.

These systems utilize real-time data from pH, EC (Electrical Conductivity), and moisture sensors to adjust the frequency and duration of irrigation cycles.

Microcontrollers and programmable logic controllers (PLCs) guarantee consistent nutrient solution levels, reducing the risk of under- or over-watering.

Studies have demonstrated that these automated systems can enhance crop yield by up to 30% compared to traditional methods.

Moreover, remote monitoring capabilities allow for adjustments and troubleshooting via mobile devices, offering unparalleled convenience and control.

This technological integration is pivotal for large-scale commercial hydroponics, ensuring resource efficiency and operational scalability.

Conclusion

The exploration of various hydroponic ebb and flow systems reveals a sophisticated range of methodologies tailored to optimize plant growth.

Basic, modular, multi-tier, vertical, and automated configurations each present unique advantages conducive to diverse horticultural applications.

The intricate design and operational mechanisms of these systems underscore their potential to revolutionize crop cultivation.

Hence, embracing these advanced hydroponic techniques could serve as a linchpin for enhancing agricultural efficiency and sustainability in an era of escalating food demands. By integrating various types of hydroponic baseboard heat systems, farmers can maintain optimal root zone temperatures, promoting healthier plant growth and increased yields. These heating methods not only enhance energy efficiency but also contribute to the overall sustainability of indoor farming operations. Consequently, adopting such innovations can help meet rising food demands while minimizing environmental impact.