Types of PVC Hydroponic System: Designs Explained!

PVC hydroponic systems are diverse and cater to various cultivation needs.

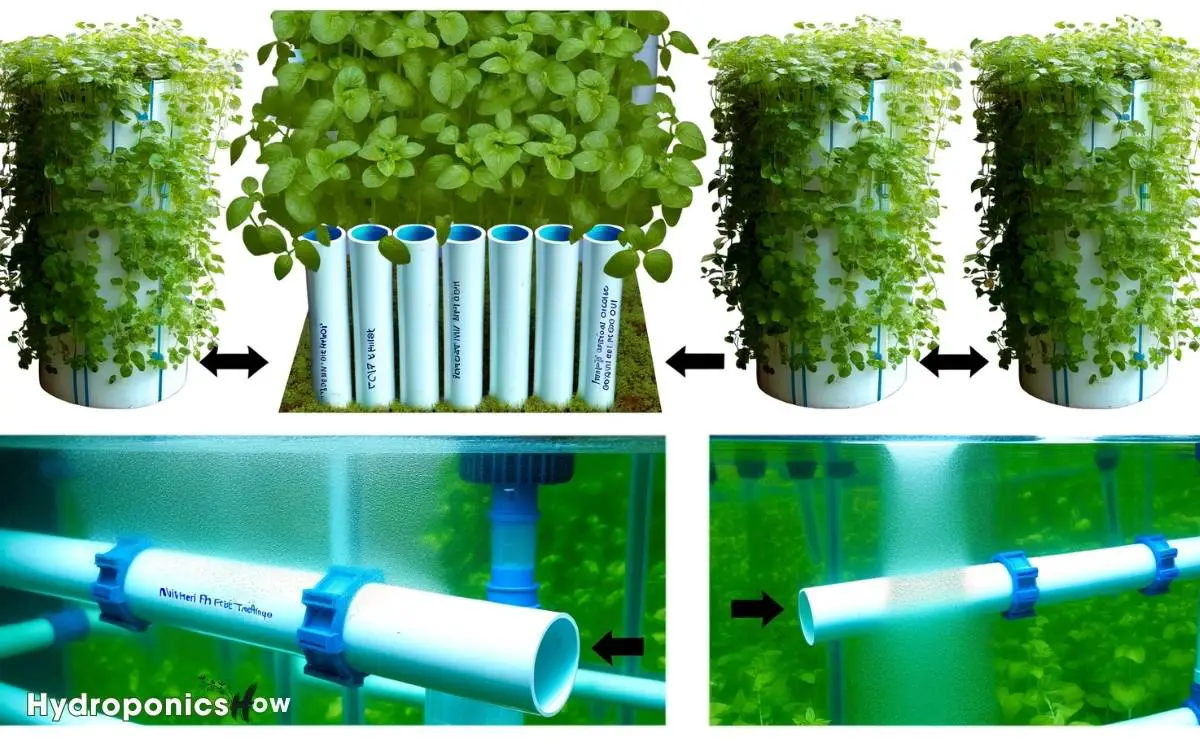

Key types include the Vertical Tower System, which maximizes plant density per unit area using vertically stacked PVC pipes, and the Horizontal Pipe System, designed for efficient nutrient distribution and space utilization.

The NFT (Nutrient Film Technique) enhances nutrient flow and absorption, while the Raft System focuses on nutrient uptake via floating rafts.

The Drip System provides precise control over irrigation, whereas the Wick System relies on passive capillary action.

Each system offers unique advantages for plant health and resource management, further insights into which can enhance agricultural efficiency and yield.

Key Takeaways

Vertical Tower System

The Vertical Tower System is an innovative approach in hydroponics. It utilizes a space-efficient design where nutrient-enriched water is circulated through vertically stacked PVC pipes, enabling ideal plant growth in limited spaces.

This system capitalizes on verticality, greatly increasing the plant density per unit area.

Nutrient solutions are pumped from a reservoir to the top of the tower and trickle down through the roots of each plant. This guarantees ideal nutrient uptake and oxygenation. The closed-loop system minimizes water waste, making it environmentally sustainable.

Specialized grow lights can be integrated to enhance photosynthesis. Properly calibrated pH and electrical conductivity (EC) levels are essential for maintaining nutrient balance.

Vertical Tower Systems are particularly advantageous for urban agriculture and commercial-scale production.

Horizontal Pipe System

Horizontal Pipe Systems in hydroponics revolutionize nutrient delivery by utilizing PVC pipes aligned horizontally to supply nutrient solutions directly to plant roots.

Precision engineering ensures optimal distribution of nutrients and water, with each pipe punctured at regular intervals to accommodate net pots for plant anchoring.

This design promotes ideal root exposure to the nutrient solution, fostering robust plant growth through continuous nutrient flow.

The system’s horizontal layout simplifies maintenance and monitoring, while the PVC material offers durability, lightweight properties, and cost-effectiveness, being resistant to corrosion.

Ideal for leafy greens and herbs, this system maximizes space efficiency and scalability for various hydroponic setups, from small-scale to commercial operations.

This innovative configuration in hydroponics enhances nutrient delivery, promotes healthy plant growth, and supports efficient space utilization and scalability.

NFT (Nutrient Film Technique)

The NFT (Nutrient Film Technique) system maximizes a continuous flow of nutrient-rich solution over the plant roots, enhancing nutrient absorption and promoting robust plant growth.

Key aspects include precise system design to guarantee uniform nutrient distribution and efficient nutrient flow dynamics to prevent stagnation and nutrient depletion.

This technique greatly enhances plant growth efficiency by maintaining ideal oxygen levels and nutrient availability.

System Design Basics

In designing a Nutrient Film Technique (NFT) hydroponic system using PVC, it is essential to ensure that nutrient delivery channels maintain a slight gradient to facilitate peak nutrient flow and root exposure.

The ideal slope ranges between 1-2%, ensuring a consistent, shallow film of nutrient solution.

PVC pipes, selected for their durability and ease of customization, should be arranged in parallel rows to maximize space utilization and light exposure.

Root support is provided through net pots suspended in holes cut into the PVC, allowing roots to dangle freely in the nutrient film.

The system requires a reservoir, a submersible pump, and timers to regulate nutrient delivery, ensuring that plants receive consistent, well-oxygenated nutrient solution without risk of waterlogging.

Nutrient Flow Dynamics

Ideal nutrient flow dynamics in a Nutrient Film Technique (NFT) hydroponic system are vital for maintaining efficient nutrient uptake and healthy plant growth.

The system operates by maintaining a thin film of nutrient-rich water flowing continuously over the root zone. This flow must be meticulously calibrated to achieve the best nutrient delivery without waterlogging the roots.

A consistent, shallow stream facilitates oxygenation, preventing anaerobic conditions detrimental to plant health.

The nutrient solution’s pH and electrical conductivity (EC) levels require regular monitoring and adjustment to sustain the precise balance necessary for nutrient absorption.

The flow rate, typically between 1-2 liters per minute, should be uniform across channels to avoid nutrient imbalances and ensure homogeneous growth conditions for all plants involved.

Plant Growth Efficiency

Maintaining ideal nutrient flow dynamics directly influences plant growth efficiency in Nutrient Film Technique (NFT) systems by ensuring that plants receive a consistent supply of essential nutrients and oxygen.

In NFT systems, a thin film of nutrient-rich water circulates over the roots, optimizing uptake and reducing nutrient wastage. The system’s design minimizes water stagnation, decreasing the likelihood of root diseases.

This continuous flow promotes robust root development, leading to enhanced nutrient absorption. Additionally, the consistent oxygenation of the root zone prevents anaerobic conditions, which can hamper plant growth.

Raft System

Employing a raft system in hydroponics involves suspending plant roots in a nutrient-rich, oxygenated water solution, allowing for efficient nutrient uptake and robust growth.

This method, also known as a deep water culture (DWC) system, is widely recognized for its simplicity and effectiveness in promoting plant health.

The raft system consists of a floating platform which holds plants in net pots above a reservoir filled with a nutrient solution. Oxygenation is crucial, typically achieved through air stones or diffusers to maintain dissolved oxygen levels.

Key components include:

- Floating rafts: Styrofoam or similar materials that hold plants securely.

- Net pots: Containers that support plants while allowing root penetration.

- Nutrient solution: A balanced mix of essential minerals.

- Aeration system: Ensures adequate oxygen supply to roots.

Drip System

A drip system in hydroponics delivers nutrient solution directly to the base of each plant through a network of tubes and emitters, allowing for precise control over water and nutrient distribution.

This method employs a pump to transport the nutrient solution from a reservoir to each plant site, guaranteeing uniform delivery.

Emitters can be adjusted to control the flow rate, accommodating varying plant needs. The excess solution is typically collected in a recovery system, promoting resource efficiency. Drip systems are highly scalable and suitable for both small and large-scale operations.

The use of PVC pipes in the construction ensures durability and ease of maintenance, making it a top choice for growers seeking a reliable and customizable hydroponic solution. Additionally, PVC pipes are lightweight and resistant to corrosion, which further enhances their longevity in hydroponic setups. Their smooth interior surface helps maintain consistent water flow, reducing the risk of clogs and algae buildup. For those wondering what PVC pipe for hydroponics is best, choosing food-grade, UV-resistant options ensures safety and durability in various growing conditions.

Wick System

Unlike more complex hydroponic systems, the wick system operates on a passive mechanism, utilizing capillary action to deliver nutrient solution from the reservoir to the plant roots through absorbent wicks.

This low-maintenance method is ideal for beginners due to its simplicity and minimal electrical requirements.

The efficiency of nutrient absorption is influenced by the type of wick material used and the capillarity properties of the nutrient solution.

- Simplicity: No moving parts, reducing potential points of failure.

- Cost-Effectiveness: Minimal initial investment and operational costs.

- Suitability: Best for small-scale or hobbyist hydroponics setups.

- Limitations: Inefficiency in supporting larger plants with high nutrient demands.

Ebb and Flow System

The Ebb and Flow system, also known as the flood and drain system, utilizes a submersible pump to periodically flood the grow tray with nutrient solution and then allows it to drain back into the reservoir, facilitating efficient nutrient uptake and oxygenation of the plant roots.

This cyclical process guarantees that plants receive ideal amounts of nutrients and oxygen. The system employs a timer to control the pump, ensuring precise flooding intervals.

Additionally, the grow tray is often filled with inert growing mediums like clay pellets or rockwool, which provide stability and further enhance root aeration.

The Ebb and Flow system is highly effective for a variety of plants, offering flexibility and scalability for both small and large-scale hydroponic operations.

Aeroponic System

The Aeroponic System represents an advanced hydroponic method by utilizing root mist nutrient delivery to promote maximum nutrient uptake.

This technique facilitates an oxygen-rich growth environment, promoting accelerated plant development and enhanced root system health.

Employing PVC components in this system can further enhance efficiency and durability, making it a preferred choice for precision agriculture.

Root Mist Nutrient Delivery

Leveraging advanced technology, the aeroponic system employs a misting mechanism to deliver nutrient-rich solutions directly to the plant roots, ensuring peak absorption and growth efficiency.

This method allows for precise control over nutrient delivery, greatly enhancing the cultivation process.

By maintaining an ideal nutrient-to-water ratio, aeroponic systems promote rapid plant growth and higher yields compared to traditional hydroponic methods.

- Micro-Mist Nozzles: Utilize fine spray to maximize nutrient uptake.

- Nutrient Solution Reservoir: Stores and recirculates the essential nutrient mix.

- Automated Timer Systems: Schedule misting intervals for consistent root hydration.

- PVC Piping: Provides a durable, corrosion-resistant framework for nutrient distribution.

These components collectively create a sophisticated environment conducive to superior plant health and productivity.

Oxygen-Rich Growth Environment

In addition to efficient nutrient delivery, aeroponic systems create an oxygen-rich growth environment that greatly enhances root respiration and overall plant health.

This system suspends plant roots in air, periodically misting them with nutrient solutions, thereby maximizing oxygen exposure.

Enhanced oxygen availability facilitates aerobic respiration, which is crucial for peak energy production within root cells. This process guarantees robust root development and accelerates nutrient uptake.

Moreover, the continuous aeration prevents anaerobic conditions, reducing the risk of root diseases such as root rot.

The precise control of environmental parameters in aeroponics allows for consistent, high-quality yields. Given these attributes, aeroponic systems are highly effective for cultivating a wide range of crops, from leafy greens to fruit-bearing plants.

Dutch Bucket System

A Dutch Bucket System, also known as a Bato Bucket System, employs individual containers for each plant, optimizing nutrient delivery and water efficiency in hydroponic cultivation.

This system is particularly advantageous for growing larger plants such as tomatoes and cucumbers, offering precise control over the root environment.

Each bucket is connected to a central nutrient reservoir through drip irrigation, ensuring consistent and targeted feeding.

- Scalability: Easily expandable by adding more buckets without significant modifications.

- Versatility: Suitable for various plant types, particularly larger crops.

- Efficient Resource Use: Minimizes water and nutrient waste through recirculation.

- Maintenance: Simplified due to isolated plant environments, reducing disease spread and allowing easy individual plant management.

This method enhances both productivity and resource efficiency in hydroponic systems.

Aquaponic Integration

Aquaponic integration merges the principles of hydroponics and aquaculture, creating a symbiotic environment where aquatic animals and plants mutually benefit from each other’s biological processes.

In this system, fish waste provides an organic nutrient source for plant growth, while the plants filter and purify the water, which is recirculated back to the fish tanks.

Utilizing PVC piping within aquaponic systems enhances the structural integrity and allows for efficient water flow management. The design typically includes components such as grow beds, sump tanks, and biofilters, ensuring ideal conditions for both plant and aquatic life.

DIY PVC System

Constructing a DIY PVC hydroponic system requires a deep understanding of hydroponic principles and precise construction techniques to guarantee the best nutrient delivery and plant growth.

Essential components include:

- PVC Piping: Select high-quality, food-grade PVC pipes to construct the framework. Different diameters cater to various plant sizes and support system stability.

- Water Pump: A reliable submersible pump ensures continuous nutrient flow. Choose one with adjustable flow rates to accommodate system size.

- Nutrient Solution Reservoir: A sturdy, non-reactive container stores the nutrient solution, maintaining consistent pH and concentration levels.

- Net Pots and Grow Media: Utilize net pots to hold plants, and appropriate growing media (e.g., clay pellets) to support root development and efficient nutrient uptake.

Each element must be meticulously assembled to achieve the best hydroponic functionality.

Commercial PVC Systems

Commercial PVC systems represent an advanced application of hydroponic technology, leveraging sophisticated engineering and high-quality materials to optimize large-scale plant production.

These systems are designed to guarantee efficiency through precise nutrient delivery and environmental control.

Utilizing robust PVC piping, they guarantee durability and resistance to corrosion, which is critical for sustained operation in commercial settings.

Advanced automation integrates seamlessly with these systems, allowing real-time monitoring and adjustments to pH levels, nutrient concentration, and water flow rates. This level of control minimizes resource wastage and enhances crop yields.

Additionally, modular construction facilitates scalability, enabling easy expansion as demand grows. By incorporating state-of-the-art technology, commercial PVC hydroponic systems offer a reliable and efficient solution for high-volume agricultural enterprises.

Conclusion

Essentially, the various types of PVC hydroponic systems symbolize a labyrinth of innovation and sustainability within agricultural engineering.

Whether it be the vertical tower or the nutrient film technique, each system represents a unique pathway towards optimizing plant growth and resource efficiency.

By exploring these structures, one enters a space where technology and nature intertwine, fostering a future where food production transcends traditional limitations.

Therefore, these systems are not mere apparatuses but harbingers of agricultural evolution.