What Type of Filter Do I Need for Hydroponics? Solutions!

Selecting the appropriate filter for your hydroponic system is critical for water quality and plant health.

- Mechanical filters, like sponge and mesh filters, remove debris and particulates.

- Biological filters employ beneficial microorganisms to convert harmful compounds.

- Chemical filters, using activated carbon and ion exchange resins, eliminate dissolved contaminants.

- UV sterilizers guarantee microbial control by eradicating harmful pathogens with ultraviolet light.

- Regular maintenance, including cleaning and replacing filter media, is essential for peak performance.

Understanding these filter types and their functions helps in making an informed decision. If you want to optimize your hydroponic setup further, continue exploring advanced filtration techniques.

Key Takeaways

Importance of Filters

Given the vital role water quality plays in hydroponic systems, the implementation of effective filtration mechanisms is essential to guarantee the best possible plant health and growth.

Hydroponic systems rely on nutrient-rich water solutions to deliver essential minerals directly to plant roots. Contaminants such as particulate matter, pathogens, and dissolved impurities can disrupt nutrient uptake, leading to impaired growth or disease.

Effective filtration ensures that water remains free from harmful substances, maintaining ideal pH levels and nutrient balance. High-quality filters remove debris and microbial contaminants, reducing the risk of root rot and other waterborne diseases.

This not only enhances plant health but also improves overall system efficiency, ensuring consistent and robust crop yields.

Mechanical Filters

Mechanical filters play a vital role in hydroponic systems by effectively removing particulate matter and debris, thereby ensuring excellent water quality.

The efficiency of these filters in capturing contaminants directly impacts the maintenance frequency, necessitating regular inspections to prevent clogging and system inefficiencies.

Additionally, the compatibility of mechanical filters with various hydroponic setups must be carefully considered to maintain seamless integration and performance.

Debris Removal Efficiency

The efficacy of mechanical filters in hydroponic systems is determined by their ability to efficiently capture and remove particulate debris, thereby maintaining peak water quality and system performance.

Mechanical filters, such as sponge, mesh, and pre-filters, are designed to intercept solid waste, undissolved nutrients, and organic matter. Their effectiveness hinges on pore size and material composition, which dictate the range of particle sizes filtered out.

High-efficiency filters can capture finer particulates, hence preventing clogging of pumps and emitters, and reducing biofilm formation.

The selection of an appropriate mechanical filter is important for optimizing water clarity and nutrient delivery, thereby ensuring a stable growing environment for plants.

Precision in filter choice directly correlates with improved system longevity and plant health.

Filter Maintenance Frequency

Regular maintenance of mechanical filters is essential for sustaining peak filtration performance and ensuring the longevity of hydroponic systems.

Mechanical filters typically require cleaning every one to two weeks, depending on the system’s load and the size of particulate matter present.

High-efficiency systems that handle substantial plant debris may necessitate more frequent attention.

To maintain top filtration, it is vital to disassemble the filter, thoroughly rinse all components with clean water, and inspect for wear or clogging. Replacement of filter media should follow manufacturer guidelines, usually every few months.

Consistent maintenance prevents blockages, enhances water flow, and supports a stable growing environment, ultimately fostering healthier plant growth and maximizing system efficiency.

Compatibility With Systems

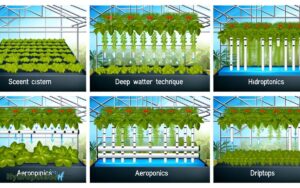

Ensuring compatibility of mechanical filters with various hydroponic systems requires a thorough understanding of system specifications, including flow rate, particulate load, and the specific needs of the plants being cultivated.

Different hydroponic systems such as NFT, DWC, or aeroponics demand specific filtration capacity and efficiency to maintain peak nutrient solutions.

Selecting a filter that matches the system’s flow rate is essential to prevent clogging and maintain uniform water distribution.

Additionally, the particulate load, which includes organic and inorganic debris, must be considered to ensure that the chosen filter can effectively remove contaminants without frequent maintenance interruptions.

Properly matched filters enhance system performance, ensuring healthier plant growth and maximizing yield potential.

As such, a detailed assessment of system parameters is indispensable for filter selection.

Biological Filters

Biological filters, essential for maintaining nutrient balance and water quality in hydroponic systems, utilize beneficial microorganisms to convert harmful compounds into less toxic forms.

These filters facilitate the nitrification process, where nitrifying bacteria oxidize ammonia into nitrites and subsequently into nitrates, which plants can readily absorb.

The biofilm that develops within the filter media serves as a habitat for these microorganisms, ensuring continuous biological activity.

Effective biological filtration mitigates the risk of toxic ammonia and nitrite accumulation, promoting ideal plant health and growth.

Properly establishing and maintaining these filters requires a stable environment, including adequate oxygen levels and consistent temperatures, to support microbial life. Regular monitoring is important to guarantee the biological filter’s efficiency remains uncompromised.

Chemical Filters

Chemical filters in hydroponic systems employ various substances, such as activated carbon or ion exchange resins, to remove dissolved impurities and contaminants from the nutrient solution, thereby enhancing water quality and ensuring ideal plant growth.

These filters are critical in maintaining the perfect balance of nutrients and preventing the accumulation of harmful chemicals.

Activated carbon, for instance, adsorbs organic compounds and chlorine, while ion exchange resins target specific ions that may disrupt the nutrient balance.

Benefits of chemical filters include:

- Improved nutrient uptake: Guarantees plants receive the precise nutrients they need.

- Protection against toxins: Eliminates potentially harmful substances.

- Stable pH levels: Prevents drastic pH fluctuations.

- Enhanced water clarity: Boosts light penetration for photosynthesis.

- Extended system lifespan: Reduces wear and tear on hydroponic equipment.

UV Sterilizers

In addition to chemical filters, UV sterilizers serve as a powerful tool for maintaining water purity in hydroponic systems. They use ultraviolet light to eradicate harmful microorganisms by exposing water to UV-C light.

This light penetrates the cellular structure of bacteria, viruses, and algae, disrupting their DNA and rendering them inactive. The method is highly effective, providing a chemical-free solution to microbial contamination.

The efficiency of UV sterilizers depends on factors such as the intensity of the UV light, exposure time, and water clarity.

Proper installation and maintenance are crucial, including regular cleaning of the UV lamp and quartz sleeve. These steps are essential to guarantee optimal performance and longevity of the sterilizer.

This technology is indispensable for achieving sterile conditions in hydroponic environments.

Activated Carbon Filters

Activated carbon filters are an essential component in hydroponic systems. They are crucial due to their efficacy in purifying water by adsorbing a wide range of unwanted contaminants.

These filters operate through a process of physical adsorption. Activated carbon’s highly porous structure traps impurities such as chlorine, volatile organic compounds (VOCs), and other chemical pollutants.

By ensuring cleaner water, activated carbon filters play a vital role in the health and growth of hydroponically cultivated plants.

Purifying Water Effectively

By utilizing the porous structure of activated carbon, hydroponic systems can effectively remove impurities and contaminants from the water, ensuring ideal plant growth and health.

The activated carbon works by adsorbing a wide range of organic and inorganic substances, thereby maintaining a cleaner and more stable nutrient solution.

Activated carbon filters are particularly proficient in eliminating chlorine, chloramine, and volatile organic compounds (VOCs), which can be detrimental to plant development.

Key benefits include:

- Enhanced Nutrient Uptake: Ensures that plants absorb nutrients more efficiently.

- Improved Water Quality: Removes harmful chemicals that can limit plant growth.

- Optimal Plant Health: Reduces the risk of diseases and nutrient lockout.

- Cost-Effective Maintenance: Prolongs the lifespan of other filtration components.

- Sustainability: Provides an eco-friendly solution with renewable filtration media.

Removing Unwanted Contaminants

Eliminating unwanted contaminants from hydroponic systems is essential for fostering peak plant growth, and activated carbon filters play a pivotal role in this process.

These filters utilize activated carbon, known for its high adsorption capacity, to remove organic compounds, chlorine, and other impurities from the nutrient solution.

The porous structure of activated carbon provides an extensive surface area, enabling it to trap contaminants effectively.

By eliminating these pollutants, activated carbon filters help maintain a clean, stable environment, ensuring that plant roots can efficiently absorb nutrients without interference.

This purification process not only enhances water quality but also contributes to the overall health and productivity of the hydroponic system, making activated carbon filters an indispensable component for serious growers.

Sediment Filters

Sediment filters play a crucial role in hydroponic systems by removing particulate matter that can clog equipment and hinder plant growth.

These filters are essential for maintaining a clean nutrient solution, guaranteeing ideal conditions for plant health. They work by capturing particles such as sand, silt, and rust, which if left unchecked, could obstruct water flow and damage pumps.

A high-quality sediment filter offers the following advantages:

- Enhanced system efficiency: Prevents clogging of delicate equipment.

- Improved plant health: Ensures a cleaner nutrient solution.

- Reduced maintenance: Minimizes the need for frequent cleaning.

- Extended equipment lifespan: Protects pumps and other components.

- Consistent nutrient delivery: Maintains ideal water flow.

Selecting the correct sediment filter is crucial for the success of any hydroponic setup.

Foam Filters

Foam filters are an essential component in hydroponic systems, designed to capture and remove fine particulate matter and organic debris, ensuring a clean and efficient nutrient solution.

These filters operate by providing a high surface area for particles to adhere to, which helps maintain a stable growing environment.

They are particularly effective in systems with a high concentration of organic matter, such as those utilizing fish or organic nutrient sources.

The table below offers a clear comparison of foam filters:

| Feature | Description | Benefit |

|---|---|---|

| High Surface Area | Large contact area for trapping particles | Enhanced filtration efficiency |

| Porosity Variance | Different pore sizes available | Customizable to specific needs |

| Reusability | Can be cleaned and reused multiple times | Cost-effective and sustainable |

Foam filters are integral for maintaining the health of hydroponic systems.

Choosing the Right Filter

Selecting the appropriate filter for a hydroponic system involves taking into account factors such as the type of particulate matter present, system capacity, and specific crop requirements.

An effective filter guarantees ideal nutrient delivery and root health, thereby enhancing overall plant growth and productivity.

Here are important factors to keep in mind when choosing the right filter:

- Particulate Size: Evaluate the size of debris and particles that need to be filtered out.

- Flow Rate: Make sure the filter can handle the system’s water flow without causing pressure drops.

- Filter Material: Choose materials that are durable and compatible with the hydroponic environment.

- Maintenance Frequency: Consider how often the filter will need to be cleaned or replaced.

- Compatibility: Ensure the filter fits seamlessly with existing system components.

Selecting wisely guarantees a thriving hydroponic setup.

Filter Maintenance

Filter maintenance is crucial to guarantee peak performance and longevity of your hydroponic system. Implementing a regular cleaning schedule is key.

Timely replacement of filter media is also essential. Thorough inspection for clogs should be done regularly. These measures will prevent blockages, promote proper nutrient flow, and maintain the health of your plants.

It is important to remember that neglecting filter maintenance can lead to decreased efficiency and potential system failures. Regular upkeep will ensure that your hydroponic system operates smoothly and effectively in the long run.

Regular Cleaning Schedule

Establishing a consistent cleaning schedule is crucial for maintaining the peak performance and longevity of hydroponic filters. Regular maintenance prevents blockages, promotes ideal water flow, and enhances nutrient absorption by plants.

A well-structured cleaning regimen includes several critical steps:

- Inspect filters weekly for debris and blockages.

- Rinse filters bi-weekly with lukewarm water to remove accumulated particulates.

- Use a soft brush to gently scrub filter surfaces, making sure not to damage delicate components.

- Check for wear and tear monthly, identifying any parts that may need replacement.

- Sanitize filters quarterly with an appropriate, hydroponic-safe disinfectant to prevent pathogen buildup.

Adhering to these practices ensures your hydroponic system functions efficiently, promoting healthier plant growth and higher yields. Additionally, regular monitoring of nutrient levels and system components helps prevent potential issues before they affect plant health. Understanding the differences between aeroponics vs hydroponics can also aid in optimizing your setup, as each method has unique advantages depending on your specific needs. By maintaining a clean and well-regulated environment, you can maximize productivity and achieve consistent, high-quality harvests.

Replacing Filter Media

In addition to regular cleaning, periodically replacing the filter media is essential for maintaining excellent filtration efficiency and ensuring the overall health of your hydroponic system.

Filter media, such as activated carbon, mechanical sponges, or bio-balls, degrade over time and lose their effectiveness.

For instance, activated carbon becomes saturated with impurities, reducing its capacity to purify water.

Mechanical sponges may become clogged with particulate matter, impeding water flow and reducing oxygen levels. Bio-balls, essential for biological filtration, can accumulate harmful biofilm if not replaced periodically.

To prevent these issues, adhere to manufacturer recommendations for filter media replacement intervals. Regular replacement not only sustains ideal water quality but also prevents the buildup of toxins that could jeopardize plant health.

Inspecting for Clogs

Regularly monitoring the filter for clogs is essential to guaranteeing ideal water flow and maintaining the overall efficiency of your hydroponic system.

Neglecting this critical aspect can lead to a cascade of issues, including reduced nutrient uptake and potential plant stress.

To effectively inspect for clogs:

- Visual Inspection: Regularly check the filter housing and media for debris buildup.

- Flow Rate Monitoring: Compare current water flow rates to baseline measurements.

- Pressure Checks: Assess any unusual pressure increases in the system.

- Routine Cleaning: Implement a schedule for periodic removal of filter components for cleaning.

- Replacement Indicators: Be alert to signs that the filter media needs replacing, such as discoloration or persistent clogs.

Consistent maintenance ensures peak performance and longevity of your hydroponic setup.

Common Filter Issues

Hydroponic systems frequently encounter filter clogging due to the accumulation of organic matter, mineral deposits, and algae growth, which can impede water flow and nutrient delivery.

Organic matter such as plant roots and decomposed material can obstruct filter screens, reducing efficiency.

Mineral deposits, particularly from hard water, can form scale, further restricting flow. Algae proliferation within the system can exacerbate blockages, leading to reduced oxygen levels and compromised plant health.

Additionally, improper filtration media or inadequate filter maintenance can exacerbate these issues, causing nutrient imbalances and system inefficiencies.

Understanding these common filter problems is essential for maintaining an ideal hydroponic environment, ensuring consistent nutrient availability, and promoting robust plant growth.

Tips for Optimal Filtration

To achieve peak filtration in hydroponic systems, it is essential to select appropriate filter media that effectively addresses the specific contaminants present in the nutrient solution. Implementing ideal filtration practices requires a thorough understanding of filter types and their functionalities.

Here are key tips to guarantee superior filtration:

- Select high-quality mechanical filters to capture particulate matter, preventing clogging and ensuring smooth nutrient flow.

- Incorporate activated carbon filters to remove organic compounds and impurities, enhancing water quality.

- Regularly clean and replace filters to maintain efficiency and avoid system downtime.

- Utilize UV sterilizers to eliminate pathogens and algae, promoting a healthier growing environment.

- Monitor pH and nutrient levels consistently to ensure the filtration system is functioning optimally.

These strategies will greatly enhance the performance of your hydroponic system.

Conclusion

In the intricate dance of hydroponic systems, filters serve as the unsung heroes, ensuring nutrient solutions remain pristine.

Mechanical filters capture debris, biological filters foster beneficial bacteria, chemical filters remove impurities, and UV sterilizers neutralize pathogens.

Choosing the appropriate filter depends on specific system requirements and ongoing maintenance is vital to prevent common issues.

By prioritizing ideal filtration, hydroponic cultivators can create an environment where plants thrive, akin to an orchestra performing in perfect harmony.