10 Key Differences: Circulating Vs Non-Circulating Hydroponics

Circulating hydroponic systems utilize continuous nutrient flow, ensuring consistent nutrient availability and efficient oxygenation through mechanical means, making them suitable for high-maintenance, high-yield crops. In contrast, non-circulating systems, characterized by static nutrient solutions and passive oxygenation, are simpler and have lower initial costs but may incur higher ongoing expenses due to resource consumption and increased maintenance needs.

Nutrient stratification and pH management are critical in non-circulating setups. Selection between the two should consider factors like crop type, resource availability, and scalability requirements.

For a more thorough understanding of how these systems can impact your specific hydroponic setup, continue exploring the detailed comparisons.

Key Takeaways

- Circulating systems provide continuous nutrient flow, ensuring consistent availability and reducing resource waste.

- Non-circulating systems are simpler and have lower initial setup costs but may require more frequent nutrient replenishments.

- Circulating systems offer better oxygenation through constant movement or air pumps, crucial for preventing root rot.

- Maintenance for circulating systems is more intensive due to moving parts and regular checks on pumps and nutrients.

System Overview

Hydroponics systems are innovative agricultural technologies that facilitate plant growth without soil, using nutrient-rich water solutions.

These systems can be broadly categorized into circulating and non-circulating types.

Circulating systems, also known as recirculating or closed systems, continuously pump the nutrient solution through the plant roots, ensuring consistent nutrient availability and efficient water use.

Conversely, non-circulating systems, or open systems, deliver the nutrient solution to the plant roots in a one-way flow, reducing mechanical complexity but potentially increasing water and nutrient consumption.

Both methods offer unique advantages and challenges, making the selection dependent on factors such as crop type, resource availability, and desired scalability.

Understanding these systems' operational dynamics is essential for optimizing plant health and maximizing yield.

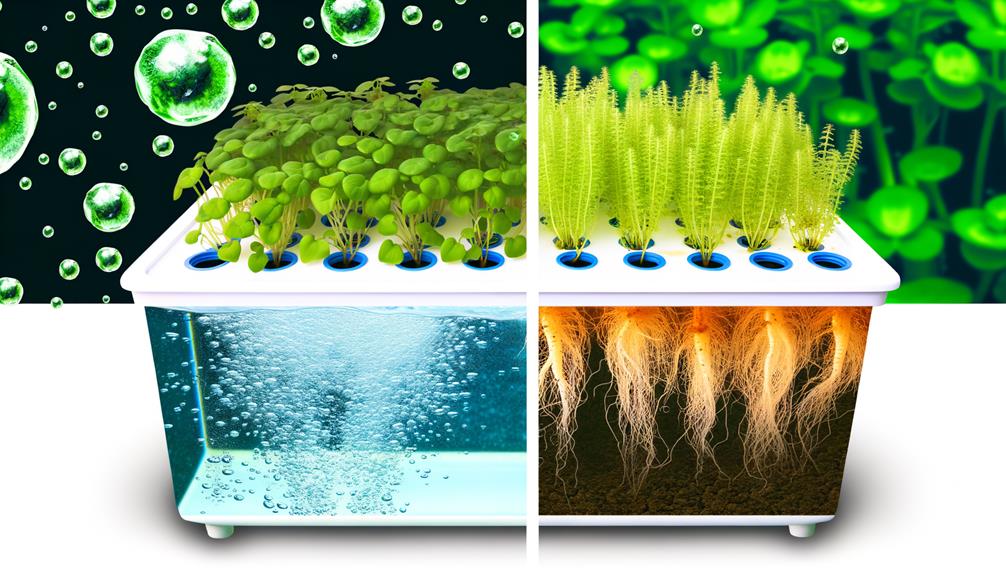

Nutrient Delivery

Guaranteeing precise nutrient delivery in hydroponics systems is critical for achieving perfect plant growth and maximizing agricultural yield.

In circulating hydroponics, nutrient solutions are continuously moved through the system, providing consistent nutrient availability. This method allows for real-time adjustments and uniform nutrient distribution.

Conversely, non-circulating systems rely on a static nutrient solution, which can lead to nutrient stratification and requires careful monitoring to maintain balance.

Key considerations include:

- Nutrient Concentration: Maintaining ideal levels to prevent deficiencies or toxicities.

- pH Stability: Guaranteeing the nutrient solution remains within the ideal pH range for nutrient uptake.

Understanding these factors is essential for effective nutrient management in both types of hydroponic systems.

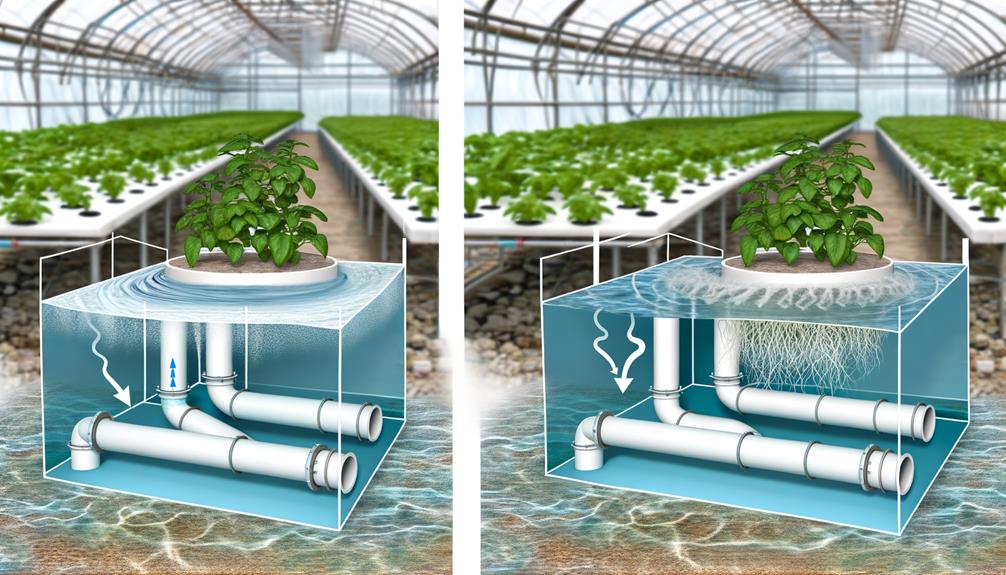

Oxygenation

Consistently maintaining adequate oxygen levels in the root zone is essential for ideal plant health and growth in hydroponic systems. Oxygenation facilitates root respiration, nutrient uptake, and overall metabolic function.

In circulating hydroponics, systems such as nutrient film technique (NFT) and deep water culture (DWC) utilize continuous water flow or air pumps to guarantee a constant oxygen supply. Conversely, non-circulating systems like the Kratky method rely on static water levels, with air gaps above the nutrient solution to provide passive oxygenation.

Research indicates that less-than-ideal oxygen levels can lead to hypoxic stress, root rot, and diminished growth rates. Consequently, selecting a system that meets the oxygenation needs of specific plant species is critical for achieving superior hydroponic performance.

Maintenance Requirements

Proper maintenance of hydroponic systems is essential to guarantee peak plant growth and system longevity.

Circulating systems require more frequent oversight due to their reliance on pumps and moving parts, which necessitate regular inspection and cleaning to prevent clogs and mechanical failures.

Non-circulating systems, while simpler, still demand consistent attention to nutrient solution levels and pH balance.

Key maintenance tasks include:

- Monitoring and adjusting nutrient solutions: Confirming ideal nutrient concentrations and pH levels.

- Regular cleaning: Preventing algae buildup and microbial contamination.

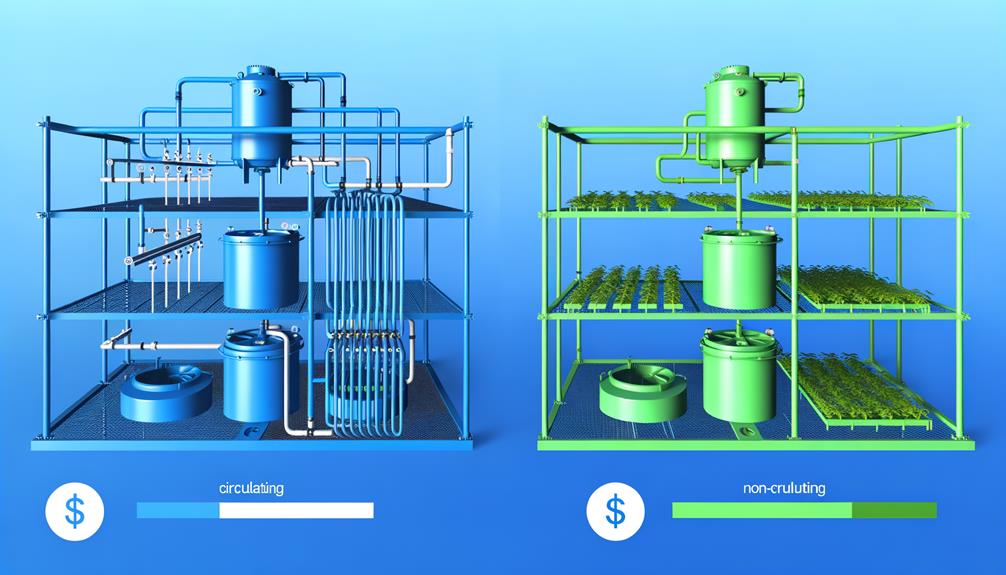

Cost Considerations

While rigorous maintenance is essential for ideal hydroponic system performance, understanding the associated costs is equally important for long-term sustainability.

Circulating systems typically incur higher initial setup costs due to the need for pumps, timers, and additional plumbing. However, they offer efficiencies in nutrient and water use that may reduce operational costs over time.

Conversely, non-circulating systems often have lower upfront costs but may require more frequent nutrient solution replacements, leading to higher ongoing expenses.

Energy consumption is another critical factor; circulating systems generally demand more electricity, impacting utility costs.

A thorough cost analysis, including capital expenditure and operational expenses, is imperative for selecting the most economically viable hydroponic system tailored to specific needs and resource availability.

Best Use Cases

When evaluating the best use cases for hydroponics systems, it is essential to take into account ideal plant varieties, space requirements, and maintenance needs.

Research indicates that certain crops, such as leafy greens and herbs, thrive exceptionally well in hydroponic environments.

Additionally, the compact nature of hydroponic setups makes them ideal for urban settings where space is limited, while the maintenance demands vary depending on the complexity of the system employed.

Optimal Plant Varieties

Hydroponic systems are particularly well-suited for cultivating leafy greens, herbs, and certain fruiting plants due to their efficient nutrient delivery and controlled environmental conditions.

Research indicates ideal plant varieties for hydroponics include:

- Leafy Greens: Varieties such as lettuce, spinach, and kale show rapid growth and high yield in hydroponic environments.

- Herbs: Basil, mint, and cilantro thrive due to the precise control over water and nutrient levels, which enhances flavor and aroma.

These plant categories leverage the hydroponic system's advantages, ensuring superior growth rates, quality, and resource efficiency.

Space Requirements

Maximizing the benefits of hydroponic systems requires an understanding of space requirements, which vary greatly based on plant type and growth stage.

In circulating systems, such as Nutrient Film Technique (NFT) and Deep Water Culture (DWC), space efficiency is achieved by enhancing vertical and horizontal arrangements. These systems are ideal for leafy greens and herbs, which require minimal root space.

Conversely, non-circulating systems like the Kratky method necessitate larger containers to support root expansion, making them suitable for larger plants or those with extensive root systems, like tomatoes and peppers.

Understanding these spatial dynamics guarantees ideal plant growth and resource utilization, particularly vital in controlled environments where space is at a premium.

Maintenance Needs

Effective maintenance of hydroponic systems hinges on understanding the specific needs and best use cases for each type of system and plant variety.

Circulating systems, such as Nutrient Film Technique (NFT) and Deep Water Culture (DWC), require regular monitoring of nutrient levels, pH balance, and pump functionality. Non-circulating systems, like the Kratky method, are less maintenance-intensive but demand periodic nutrient solution replenishment and vigilant pest management.

Maintenance tasks vary considerably based on system type:

- Circulating Systems: Frequent checks on water quality and pump operations are essential.

- Non-Circulating Systems: Regular nutrient solution top-offs and pest control are critical.

Understanding these nuances guarantees maximum plant health and system efficiency.

Conclusion

In comparing circulating and non-circulating hydroponic systems, each presents unique advantages and challenges.

Circulating systems efficiently deliver nutrients and oxygen but require more complex maintenance. Non-circulating systems offer simplicity and lower initial costs but may face challenges in oxygenation.

According to research, circulating systems can increase crop yield by up to 30% compared to non-circulating systems.

The choice between systems should be informed by specific cultivation goals, resource availability, and operational expertise.