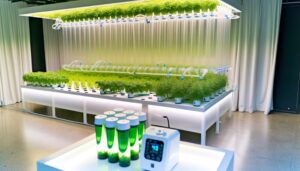

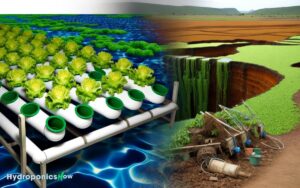

Complete Guide to Maintaining Hydroponic Plants: 5 Essential Steps

Maintaining hydroponic plants demands precise management of various factors. Regularly monitor and adjust pH levels to a range of 5.5 to 6.5, and guarantee nutrient solutions are balanced with essential macro and micronutrients, maintaining EC levels between 1.2-2.0 mS/cm.

Monitor water quality by checking dissolved oxygen, pH, and EC levels frequently. Provide 14-16 hours of full-spectrum light daily.

Ensure effective air circulation to prevent fungal growth and regulate humidity. Maintain temperatures between 65-75°F using digital thermostats and adequate ventilation.

Implement Integrated Pest Management for proactive pest control. Keep nutrient solutions within 1200-1500 ppm and system components well-maintained.

For a deeper understanding, explore each of these steps thoroughly.

Key Takeaways

- Monitor and adjust pH levels daily, maintaining a range between 5.5 and 6.5 for optimal nutrient uptake.

- Replace nutrient solutions every 1-2 weeks and verify EC levels between 1.2-2.0 mS/cm.

- Provide 14-16 hours of full-spectrum LED light daily for robust plant growth.

- Ensure effective air circulation with oscillating fans and exhaust systems to prevent fungal growth.

Monitor Ph Levels

Maintaining ideal pH levels in hydroponic systems is essential for nutrient absorption and overall plant health. Preferred pH for most hydroponic crops ranges between 5.5 and 6.5. Deviations from this range can result in nutrient lockout, impairing plant growth.

To monitor pH, utilize a reliable digital pH meter, ensuring it is calibrated regularly with standard buffer solutions (pH 4.0, 7.0, and 10.0). Take readings daily, ideally at the same time, to account for diurnal fluctuations.

When adjustment is necessary, employ pH up or pH down solutions, adding them gradually to prevent abrupt changes that could stress plants.

Document all pH readings and adjustments meticulously to identify trends and refine maintenance practices over time.

Nutrient Solutions

To guarantee ideal growth in hydroponic systems, maintaining balanced nutrient ratios is essential, involving precise concentrations of macronutrients and micronutrients.

Regular solution monitoring is vital to detect nutrient imbalances and prevent deficiencies or toxicities.

Utilize calibrated instruments to measure electrical conductivity (EC) and total dissolved solids (TDS) for accurate assessment of nutrient solution strength.

Balanced Nutrient Ratios

Achieving ideal growth in hydroponic systems necessitates precise calibration of nutrient solutions to maintain balanced nutrient ratios tailored to the specific needs of the plants.

Essential macronutrients such as nitrogen (N), phosphorus (P), and potassium (K) must be proportioned accurately, typically in a 3-1-2 ratio for vegetative growth and a 1-3-2 ratio for flowering stages.

Additionally, micronutrients like iron (Fe), manganese (Mn), and zinc (Zn) should be included in trace amounts to prevent deficiencies.

Utilizing a high-quality hydroponic nutrient mix guarantees these elements are solubilized and bioavailable.

Employing a conductivity meter and pH meter, verify that electrical conductivity (EC) levels and pH are within suitable ranges, respectively 1.2-2.0 mS/cm and 5.5-6.5, for nutrient uptake efficiency.

Regular Solution Monitoring

Consistent monitoring of nutrient solutions is essential to guarantee optimal nutrient availability and prevent imbalances that could hinder hydroponic plant growth.

Employ a high-quality pH meter and electrical conductivity (EC) meter to routinely assess the solution’s pH and nutrient concentration. Ideal pH levels generally range between 5.5 and 6.5, promoting nutrient absorption. Maintain EC values within species-specific recommendations to avoid nutrient toxicity or deficiency.

Regularly replace the nutrient solution, typically every 1-2 weeks, to prevent the accumulation of salts and pathogens. Additionally, verify dissolved oxygen levels are sufficient by using air pumps or oxygenating stones.

Document all measurements and adjustments to track trends and make informed management decisions. Accurate monitoring fosters robust plant health and maximizes yield potential.

Water Quality

Maintaining ideal water quality is essential for the health and productivity of hydroponic plants, necessitating regular monitoring and adjustment of parameters such as pH, electrical conductivity (EC), and dissolved oxygen levels.

Accurate pH control between 5.5 and 6.5 guarantees nutrient availability and uptake. Monitoring EC levels helps gauge nutrient concentration, preventing deficiencies or toxicities. Dissolved oxygen, vital for root respiration, should be maintained above 5 ppm to avoid hypoxic conditions.

Key steps include:

- pH Adjustment: Use pH up or down solutions to maintain the best range.

- EC Monitoring: Employ a calibrated EC meter to track nutrient solution strength.

These practices guarantee a balanced environment conducive to plant growth.

Lighting Requirements

Proper lighting is essential for the photosynthetic processes in hydroponic plants, necessitating an understanding of both ideal light duration and suitable light types.

Typically, hydroponic systems require 14-16 hours of light per day, with adjustments based on specific plant species.

Utilizing full-spectrum LED lights, which mimic natural sunlight, can enhance growth efficiency and guarantee robust plant development.

Optimal Light Duration

Determining the ideal light duration for hydroponic plants involves understanding the specific photoperiod requirements of the plant species being cultivated, as well as the intensity and spectrum of the artificial lighting system employed.

Prime photoperiods generally fall into three categories:

- Short-day plants: Require less than 12 hours of light per day to trigger flowering.

- Long-day plants: Thrive with 14-18 hours of light daily, promoting vegetative growth and flowering.

Adjusting light duration guarantees metabolic processes such as photosynthesis and respiration occur efficiently, maximizing growth rates and yields.

Monitoring light exposure through timers and sensors can automate these cycles, providing precision and consistency.

Suitable Light Types

Selecting the appropriate light types for hydroponic plants necessitates an understanding of the spectral needs of various plant species and the efficiency of different artificial lighting technologies.

High-Intensity Discharge (HID) lamps, such as Metal Halide (MH) and High-Pressure Sodium (HPS), offer robust light output, with MH being ideal for vegetative growth and HPS for flowering phases.

Alternatively, Light Emitting Diodes (LEDs) provide customizable spectra, energy efficiency, and lower heat output, making them a versatile choice for diverse growth stages.

Fluorescent lights, including T5 and Compact Fluorescent Lamps (CFLs), are suitable for seedlings and leafy greens due to their broad spectrum and moderate intensity.

Properly calibrating light distance and duration is essential to maximize photosynthetic efficiency and plant health.

Air Circulation

Effective air circulation is essential in hydroponic systems to prevent fungal growth, regulate humidity, and guarantee adequate oxygen exchange for plant roots. Proper air movement can be achieved through strategic use of oscillating fans and exhaust systems.

To enhance air circulation, consider the following practices:

- Install oscillating fans: Position these fans to guarantee even distribution of air across the entire grow area, minimizing stagnant zones.

- Use exhaust systems: Implement exhaust fans to expel warm, humid air and introduce fresh, oxygen-rich air, maintaining ideal humidity levels.

These steps help create a stable environment conducive to healthy plant growth.

Temperature Control

Maintaining precise temperature control is critical in hydroponic systems to guarantee ideal metabolic functioning and growth rates of plants. Optimal temperature ranges typically fall between 65-75°F (18-24°C) for most hydroponic crops.

Utilize digital thermostats and hydroponic-specific heating and cooling units to monitor and adjust temperatures accurately. Employ insulated reservoirs to maintain nutrient solution temperature within the best range, preventing thermal fluctuations.

Install fans and ventilation systems to facilitate even air distribution and prevent localized hot spots. For precise control, consider integrating environmental controllers that automate temperature regulation based on real-time data.

Regularly calibrate sensors and equipment to verify accuracy, and routinely inspect for potential malfunctions or inefficiencies. Proper temperature management is fundamental for maximizing yield and crop quality in hydroponic systems.

Pest Management

Implementing an integrated pest management (IPM) strategy is essential for controlling pest populations in hydroponic systems without compromising plant health.

IPM involves a multi-faceted approach that includes monitoring, identification, and intervention. Regularly inspect plants for signs of infestation, such as discolored leaves, webbing, or insect presence.

Employ biological controls like beneficial insects (e.g., ladybugs) to naturally reduce pest numbers. Use chemical controls as a last resort, selecting hydroponic-safe pesticides to avoid phytotoxicity.

- Monitoring and Identification: Regularly examine plants for early signs of pests to enable timely intervention.

- Biological Controls: Introduce natural predators like ladybugs or nematodes to keep pest populations in check.

Regular Maintenance

Regular maintenance of hydroponic systems involves meticulous monitoring of nutrient solution levels, pH balance, and system components to guarantee ideal plant growth and prevent potential issues. To achieve this, it is imperative to regularly check and adjust the following parameters:

| Parameter | Ideal Range | Frequency of Check |

|---|---|---|

| Nutrient Solution | 1200-1500 ppm | Daily |

| pH Balance | 5.5-6.5 | Daily |

| Water Temperature | 18-24°C | Daily |

| System Components | Functional/Non-functional | Weekly |

| Root Health | White/Clean | Weekly |

Careful adherence to these practices guarantees prime conditions for hydroponic plants, minimizing the risk of deficiencies, toxicities, or mechanical failures.

Conclusion

The meticulous stewardship of hydroponic systems encompasses vigilant monitoring of pH levels, precise formulation of nutrient solutions, stringent water quality control, ideal lighting provision, adequate air circulation, and stringent temperature regulation.

Additionally, proactive pest management and consistent maintenance are essential.

By adhering to these rigorous protocols, the health and productivity of hydroponic plants can be sustained, ensuring the realization of their full potential in a controlled environment. This approach minimizes the risk of disease and nutrient deficiencies, fostering optimal development at every stage. By following the complete hydroponic plant growth steps, growers can systematically manage water, lighting, and nutrient levels to enhance yield and quality. Consistent monitoring and adjustments further contribute to a stable and efficient growing system.

Such diligent care culminates in the flourishing of a sophisticated, high-yield cultivation system.