10 Essential Steps to Flush Your Hydroponic System

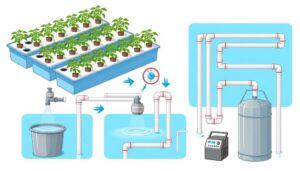

Flushing your hydroponic system is essential to remove built-up salts, contaminants, and nutrient residues, preventing root damage and maintaining a prime growth environment. Begin by turning off the power and draining the nutrient solution completely.

Disassemble components and clean them with non-abrasive brushes and mild agents, guaranteeing all soap residues are rinsed away. Prepare a flushing solution with a commercial agent and dechlorinated water, run it through the system for at least 24 hours, and then rinse with clean water.

Refill with a freshly calibrated nutrient mix to support the next growth stage. Mastering these steps guarantees peak plant health and development.

Key Takeaways

- Turn off the power and drain the nutrient solution using a siphon pump or drain valve.

- Disassemble components and clean thoroughly with non-abrasive brushes and mild, non-toxic cleaning agents.

- Prepare a flushing solution by mixing a commercial agent with dechlorinated water, adjusting pH to 6.0-6.5.

- Circulate the flush solution for at least 24 hours, ensuring even distribution and effective nutrient removal.

Understanding the Need to Flush

Flushing a hydroponic system is a critical maintenance procedure that helps remove accumulated salts, nutrient residues, and other contaminants from the growing medium and water reservoir.

Over time, these accumulations can disrupt nutrient uptake, leading to deficiencies or toxicities that adversely affect plant health and growth.

Regular flushing guarantees the system's ideal performance by resetting the nutrient solution's balance, thereby preventing root damage and promoting efficient nutrient absorption.

For innovative growers aiming for maximum yield and quality, understanding the necessity of flushing is paramount.

This practice not only prolongs the lifespan of the hydroponic system but also maintains an environment conducive to healthy, vigorous plant development.

Properly executed, it can greatly enhance overall productivity and sustainability.

Choosing the Right Time

Determining the appropriate time to flush a hydroponic system is essential for maintaining plant health and maximizing yield.

Key indicators include specific growth stages, such as pre-harvest periods, and observable signs of nutrient build-up, which can affect plant performance.

Additionally, adhering to an ideal cycle frequency guarantees the system remains balanced and nutrients are effectively managed.

Growth Stage Indicators

Identifying the ideal time to flush a hydroponic system hinges on carefully observing specific growth stage indicators that signal the plant's readiness for nutrient adjustment.

These indicators include the shift from vegetative to flowering stages, where nutrient requirements change considerably. During the pre-flowering phase, plants demand a higher concentration of phosphorus and potassium, necessitating a nutrient flush to prevent imbalances.

Additionally, monitoring leaf coloration and growth patterns provides critical insights. Yellowing leaves or slowed growth can indicate nutrient lockout or excess salts, prompting a timely flush.

Precision in identifying these stages guarantees peak nutrient absorption, promoting robust growth and maximizing yield potential.

Employing advanced growth stage monitoring tools further enhances accuracy and effectiveness in nutrient management.

Nutrient Build-Up Signs

Observing nutrient build-up signs is essential for choosing the best time to flush a hydroponic system, ensuring that plants receive a balanced nutrient profile without the detrimental effects of excess salts.

Key indicators include visible salt deposits on growing medium surfaces and system components, which can impede nutrient uptake. Leaf discoloration, particularly chlorosis, and stunted growth are symptomatic of nutrient imbalance caused by excessive salts.

Conducting regular electrical conductivity (EC) measurements provides quantitative data on nutrient concentration, enabling precise adjustments. A significant rise in EC values suggests an accumulation of dissolved solids, necessitating a system flush.

Monitoring pH levels is also vital; deviations from ideal ranges indicate potential nutrient lockout, further underscoring the need for timely flushing to restore equilibrium.

Optimal Cycle Frequency

Understanding the ideal cycle frequency for flushing a hydroponic system is essential for maintaining nutrient balance and preventing adverse effects on plant health.

Typically, a bi-weekly to monthly flushing schedule is recommended, depending on the specific nutrients and plant species involved. Regular flushing helps to mitigate the risks of salt buildup and nutrient lockout, which can impede plant growth and yield.

Advanced hydroponic systems may benefit from real-time monitoring technologies to gauge electrical conductivity (EC) and pH levels, offering precise insights into when flushing is necessary.

Employing automation and sensor integration can further optimize the process, ensuring peak nutrient absorption and promoting robust plant health.

Striking the right balance fosters an innovative and efficient hydroponic environment.

Gathering Necessary Supplies

To effectively flush your hydroponic system, begin by assembling essential cleaning tools such as brushes, sterilizing agents, and buckets.

Guarantee you have the appropriate water and nutrient solutions for the flushing process, adhering to specific concentrations and pH levels.

Prioritize safety and hygiene by using gloves and sanitizing all equipment to maintain a sterile environment.

Essential Cleaning Tools

A thorough list of essential cleaning tools is paramount for guaranteeing the efficient maintenance and longevity of your hydroponic system.

Key supplies include a high-quality, non-abrasive scrub brush to remove biofilm and residues without damaging system components. A dedicated siphon pump is indispensable for effectively draining and replenishing the system's water.

Utilize a fine-mesh filter to capture debris during flushing processes. Opt for a pH meter and EC meter to guarantee nutrient solutions remain within ideal ranges post-cleaning.

Sterilize with food-grade hydrogen peroxide or isopropyl alcohol to eliminate pathogens. Microfiber cloths are recommended for drying surfaces without leaving lint.

Precision and the right tools guarantee an innovative, thriving hydroponic environment.

Water and Nutrient Solutions

Having assembled your essential cleaning tools, the next step involves gathering the appropriate water and nutrient solutions necessary for flushing your hydroponic system effectively.

Begin with dechlorinated water, as chlorine can hinder plant nutrient absorption. Utilize a reverse osmosis (RO) system or dechlorination tablets to achieve this.

For nutrient solutions, opt for a high-quality flushing agent specifically designed for hydroponic systems. These agents help in dissolving residual salts and nutrient build-up efficiently.

Make sure the flushing solution is compatible with your specific plant type to avoid nutrient shock. Carefully read the manufacturer's instructions to determine the correct dilution ratios and application frequency.

This meticulous preparation guarantees that your hydroponic system maintains peak performance and fosters robust plant growth.

Safety and Hygiene Practices

Establishing strict safety and hygiene protocols is essential to guarantee both effective system maintenance and the health of the plants.

Begin by gathering vital supplies: sterile gloves, pH-adjusted water, plant-safe disinfectants, and clean containers.

Utilize sterile gloves to prevent contamination during the flushing process.

Verify pH-adjusted water is free from impurities, maintaining ideal nutrient uptake.

Employ plant-safe disinfectants to sanitize all equipment, thereby mitigating pathogen risk.

Clean containers are important for holding nutrient solutions and waste.

Adhere to these protocols meticulously to sustain a sterile environment, fostering plant health and system longevity.

This systematic approach not only enhances operational efficiency but also aligns with innovative hydroponic practices.

Draining the System

To drain the hydroponic system effectively, begin by turning off the power supply to prevent any electrical hazards.

Once deactivated, locate the primary drain valve or outlet of your system. Using a suitable container, capture the nutrient solution as it exits to prevent spillage.

If your system lacks a dedicated drain valve, consider employing a siphon pump for efficient removal. Monitor the fluid flow meticulously to guarantee complete drainage.

Regularly check for clogs or airlocks that might impede the process. After draining, inspect the reservoir and connected tubing for residual solution to guarantee thorough emptying.

This meticulous attention to detail not only maintains system integrity but also prepares it for subsequent cleaning and nutrient replenishment phases.

Cleaning the Components

Regularly cleaning the components of your hydroponic system is essential for preventing the buildup of algae, pathogens, and mineral deposits. Neglecting proper maintenance can lead to clogged tubing, reduced nutrient absorption, and an unhealthy growing environment for your plants. To maintain system efficiency, clean reservoirs, pumps, and growing trays with a mild disinfectant and rinse thoroughly to remove any residue. Additionally, learning how to remove bugs hydroponics methods, such as introducing beneficial insects or using organic pest control solutions, can help keep your plants healthy and thriving.

Begin by disassembling key elements such as pumps, reservoirs, tubing, and grow trays.

Utilize a non-abrasive brush and a mild, non-toxic cleaning agent to scrub all surfaces, ensuring thorough removal of biological residues.

Pay special attention to corners and crevices where buildup is most likely to occur.

Rinse each component meticulously with clean water to eliminate any soap residues that could harm plant roots.

Employing ultraviolet sterilization or a dilute hydrogen peroxide solution can further enhance pathogen eradication.

Reassemble the system carefully, verifying all connections are secure to maintain peak functionality and prevent leaks.

This meticulous process fosters a healthier, more efficient hydroponic environment.

Preparing the Flush Solution

Accurately preparing the flush solution is critical for effectively clearing nutrient buildup and guaranteeing an ideal growth environment for your plants.

Begin by selecting a high-quality commercial flushing agent designed specifically for hydroponics. Follow the manufacturer's recommended dilution ratios precisely, using pure, dechlorinated water to mix the solution.

Confirm the water's pH is calibrated to a suitable level, typically around 6.0-6.5, to enhance the flushing efficiency. Utilize a clean, sterilized mixing container to prevent contamination.

Once mixed, verify the solution's electrical conductivity (EC) to ensure it aligns with the specified parameters.

Consistency in measurement and adherence to recommended guidelines guarantees the flush solution will effectively cleanse the system, paving the way for healthier plant growth and improved nutrient absorption.

Running the Flush Solution

Initiate the flushing process by carefully introducing the prepared flush solution into the hydroponic system, guaranteeing even distribution throughout the entire network. This step is essential to eliminate nutrient build-up and potential contaminants.

To achieve the best results, follow these guidelines:

- Monitor pH Levels: Regularly check the pH of the flush solution to maintain an ideal range, guaranteeing effective nutrient removal without stressing the plants.

- Circulation Time: Allow the flush solution to circulate through the system for a minimum of 24 hours. This duration guarantees thorough cleansing of all system components.

- Inspect Flow Rates: Verify that the solution flows uniformly across all channels and reservoirs, preventing localized nutrient accumulation and promoting extensive system purification.

Precision in these steps guarantees a superior flushing process.

Rinsing With Clean Water

After the flush solution has thoroughly cleansed the system, the next step involves rinsing with clean water to remove any residual flush agents and remaining contaminants. This step is critical for ensuring the integrity of the hydroponic environment and maintaining peak plant health. Follow these guidelines for effective rinsing:

| Step | Action | Duration |

|---|---|---|

| 1 | Drain flush solution | Immediate |

| 2 | Fill with clean water | 5 minutes |

| 3 | Circulate water | 15 minutes |

| 4 | Drain rinse water | Immediate |

| 5 | Repeat if necessary | As needed |

Ensure the water used is devoid of impurities and contaminants. By meticulously following these steps, you safeguard the system from any residual chemicals, setting a pristine stage for subsequent nutrient introduction.

Refilling With Fresh Nutrients

Once the system has been thoroughly rinsed, the next vital step is to refill the reservoir with a balanced nutrient solution tailored to the specific needs of your plants. This step is essential for maintaining peak plant health and maximizing growth.

Follow these steps to guarantee precision and effectiveness:

- Select Appropriate Nutrients: Choose a nutrient mix that matches the growth stage of your plants—whether vegetative or flowering. Confirm the mix contains essential macro and micronutrients.

- Measure and Mix: Accurately measure the nutrient solution according to the manufacturer's instructions. Use precise measuring tools to maintain consistency.

- Monitor and Adjust pH: After mixing, check the pH level of the solution. Adjust it to the ideal range (typically 5.5-6.5) for nutrient uptake.

These steps guarantee a robust and thriving hydroponic system.

Conclusion

In the intricate dance of hydroponic cultivation, akin to a well-conducted symphony, the act of flushing serves as the important interlude that guarantees harmony and liveliness.

Each step, from draining to refilling, mirrors the meticulous tuning of instruments, guaranteeing peak performance.

By adhering to this disciplined regimen, cultivators safeguard plant health, akin to preserving the integrity of a masterpiece.

Consequently, the periodic flushing of a hydroponic system becomes an essential ritual in the pursuit of botanical excellence.