What Is Vertical Hydroponic Farming

Vertical hydroponic farming is an advanced agricultural technique that employs multilevel, soilless cultivation systems to maximize yield per square meter. Utilizing nutrient-rich water solutions, controlled environments, and LED grow lights, this method dramatically reduces land footprint—up to 95%—and enhances resource efficiency.

Key metrics such as photosynthetic photon flux density (PPFD) and precise temperature, humidity, and CO₂ controls guarantee ideal plant growth. With yield increases of 200-300% over traditional farming and 90% reduced water usage, vertical hydroponics supports sustainable urban agriculture and consistent food production.

Discover more about the intricacies of this innovative farming method and its key components.

Key Takeaways

- Vertical hydroponic farming uses stacked layers to grow plants in a nutrient-rich water solution without soil.

- It maximizes space, enabling high plant densities and increased yields per square meter.

- Controlled environments optimize growth conditions, enhancing resource efficiency and reducing waste.

- Key components include automated nutrient systems, LED grow lights, and environmental controls.

History of Hydroponics

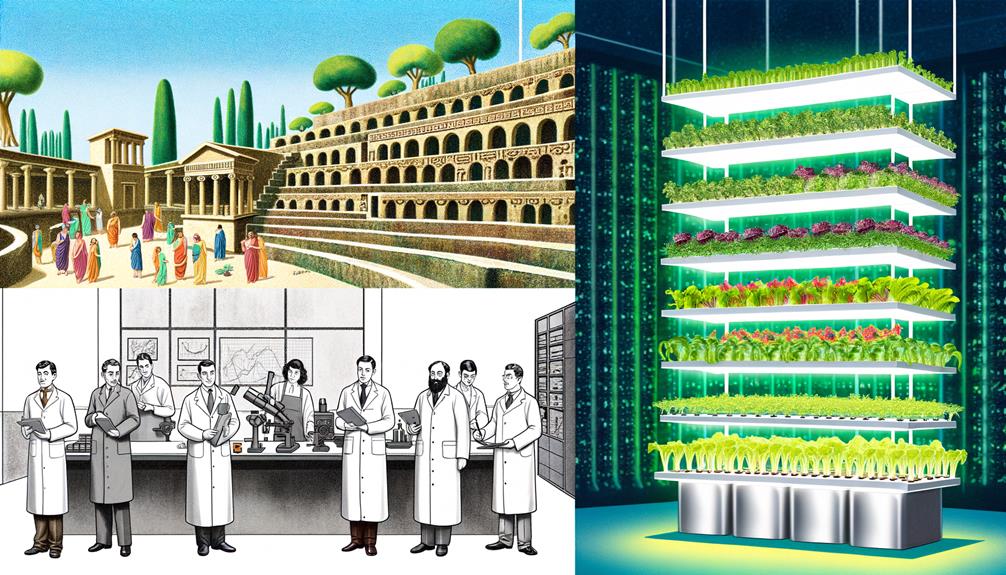

The history of hydroponics traces back to the ancient civilizations of Babylon and Egypt, where early methodologies for soil-less cultivation were documented.

Babylon's Hanging Gardens, one of the Seven Wonders of the Ancient World, utilized a primitive form of hydroponics via a complex irrigation system. Similarly, Egyptian hieroglyphs reveal the use of water culture in agriculture.

The 1920s marked a pivotal era with Dr. William Frederick Gericke's formalization of hydroponics, coining the term and pioneering controlled environment agriculture (CEA).

By the mid-20th century, advancements in nutrient solutions and synthetic substrates catalyzed commercial applications.

Modern hydroponics now leverages precise nutrient delivery systems, environmental control technologies, and data analytics, optimizing yield, resource efficiency, and crop quality for innovative agricultural practices.

Principles of Vertical Farming

Vertical farming leverages efficient space utilization by employing multi-tiered, stacked layers to maximize yield per square meter.

This layered crop system capitalizes on vertical space, enabling the cultivation of a diverse range of crops in a controlled environment.

Such arrangements can greatly enhance production efficiency, reducing the land footprint by up to 95% compared to traditional farming methods.

Efficient Space Utilization

Maximizing spatial efficiency in vertical hydroponic farming involves the strategic stacking of multiple layers of crops within a controlled environment to optimize resource utilization. This approach leverages vertical space, drastically increasing yield per square meter compared to traditional horizontal farming.

Key metrics, such as photosynthetic photon flux density (PPFD) and nutrient distribution, are meticulously monitored to guarantee uniform growth conditions across all tiers.

Benefits include:

- Increased Crop Density: More plants per unit area, resulting in higher productivity.

- Resource Optimization: Enhanced utilization of water, nutrients, and light through precise control mechanisms.

Layered Crop Systems

Implementing layered crop systems in vertical hydroponic farming necessitates the integration of advanced technology to guarantee uniform light distribution, efficient nutrient delivery, and perfect microclimatic conditions across all levels.

This approach employs LED grow lights with adjustable spectra to validate photosynthetically active radiation (PAR) is maximized, thereby maximizing crop yield.

Automated nutrient delivery systems employ precision irrigation techniques, utilizing sensors and IoT devices to monitor and adjust nutrient concentrations in real-time.

Additionally, climate control systems, including HVAC and CO2 enrichment technologies, maintain ideal temperature and humidity levels.

Data analytics derived from environmental sensors provide actionable insights, promoting continuous improvement in crop performance.

Hence, layered crop systems epitomize the pinnacle of resource efficiency and productivity in contemporary vertical farming practices.

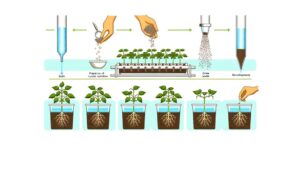

How Vertical Hydroponics Works

Utilizing a soilless growing medium, vertical hydroponic systems rely on nutrient-rich water solutions to sustain plant growth in stacked layers. These systems facilitate peak use of space through vertical integration, enabling higher crop yields in confined urban environments.

Essential components include:

- Nutrient Delivery Systems: Automated pumps and drippers guarantee precise nutrient dispersion.

- Lighting Solutions: LED grow lights provide tailored spectral outputs to maximize photosynthesis.

Plants are typically grown in inert substrates such as rock wool or coconut coir, which support root structure without soil.

The nutrient solution, meticulously formulated, circulates continuously, enhancing plant uptake and reducing waste. This method guarantees consistent and rapid growth cycles, making it ideal for modern agricultural demands.

Benefits of Vertical Hydroponics

The integration of vertical hydroponic systems into urban agriculture presents numerous advantages, including optimized space utilization, enhanced crop yields, and resource efficiency.

By leveraging vertical stacking, these systems maximize the use of limited urban spaces, allowing for considerably higher plant densities per square meter. Empirical studies demonstrate yield increases of up to 200-300% compared to traditional farming methods.

Additionally, controlled environment agriculture (CEA) within vertical hydroponics guarantees precise nutrient delivery and water usage, reducing resource consumption by up to 90%. This method also minimizes the need for pesticides and herbicides, promoting sustainable farming practices.

Moreover, vertical hydroponics supports year-round production, independent of external climatic conditions, thereby assuring consistent supply chains and contributing to urban food security.

Types of Vertical Systems

How do various configurations of vertical hydroponic systems, such as modular towers, A-frames, and rotating systems, address the unique spatial and resource challenges of urban agriculture?

Modular towers maximize vertical space utilization, allowing dense plant growth in minimal footprint areas. A-frames offer multi-tiered structures that enhance light penetration and airflow, optimizing photosynthesis and plant health. Rotating systems guarantee even light distribution and nutrient access by continuously moving plants.

Key advantages include:

- Space Efficiency: Vertical designs multiply plant density per square meter.

- Resource Optimization: Systems minimize water and nutrient waste through recirculation.

These configurations collectively advance urban agriculture's sustainability and productivity.

Key Components Needed

Key components integral to vertical hydroponic farming encompass fundamental equipment and an effective nutrient delivery system.

Fundamental equipment includes grow lights, pumps, and structural frameworks which guarantee ideal growth conditions.

The nutrient delivery system is crucial for supplying plants with precise concentrations of nutrients, directly impacting growth rates and yield efficiency.

Essential Equipment Overview

Integral to the success of vertical hydroponic farming, a thorough understanding of essential equipment—such as nutrient delivery systems, grow lights, and pH control tools—is paramount. These components guarantee ideal growth conditions and system efficiency.

Key equipment includes:

- Grow Lights: High-intensity discharge (HID), light-emitting diodes (LEDs), and fluorescent lights, each offering specific spectral qualities suited to various growth stages.

- pH Control Tools: Automated pH controllers and manual pH testing kits, critical for maintaining nutrient solution pH within the ideal range of 5.5 to 6.5.

Precision in equipment selection and utilization directly impacts yield quality and resource efficiency.

Nutrient Delivery System

Guaranteeing ideal nutrient delivery in vertical hydroponic systems necessitates the integration of advanced components such as nutrient reservoirs, pumps, and delivery mechanisms to maintain consistent and precise nutrient distribution.

Nutrient reservoirs serve as the primary storage unit for hydroponic solutions, demanding meticulous monitoring to guarantee optimal pH and electrical conductivity (EC) levels.

High-efficiency pumps facilitate seamless nutrient flow, reducing the risk of clogging and guaranteeing uniform delivery across all vertical tiers.

Precision delivery mechanisms, including drip emitters and micro-sprinklers, assure targeted nutrient application, minimizing waste and enhancing plant absorption rates.

Implementing automation technology, such as digital controllers and sensors, further elevates system efficiency by enabling real-time adjustments based on plant growth data, guaranteeing maximum yield and resource utilization.

Choosing the Right Plants

Selecting appropriate plant species is essential for optimizing the efficiency and productivity of vertical hydroponic farming systems. Determining which crops thrive in controlled environments directly correlates with yield maximization and resource utilization. Ideal candidates generally exhibit robust growth under artificial lighting and possess a compact morphology conducive to vertical stacking.

Key considerations include:

- Growth cycle duration: Shorter cycles lead to more frequent harvests.

- Root structure: Plants with smaller root systems are preferable as they require less spatial allocation.

Popular choices often involve leafy greens, herbs, and small fruiting plants, which have demonstrated superior adaptability to hydroponic conditions.

Empirical data underscores these species' efficacy in enhancing output and sustainability within vertical farming paradigms.

Nutrient Solutions Explained

Nutrient solutions are critical to vertical hydroponic farming, requiring precise formulations to guarantee ideal plant growth.

Essential components include macronutrients such as nitrogen, phosphorus, and potassium, as well as trace micronutrients like zinc and manganese.

Equally important is the careful balancing of pH levels, typically maintained between 5.5 and 6.5, to facilitate nutrient absorption.

Essential Nutrient Components

In vertical hydroponic farming, the formulation of nutrient solutions is essential, necessitating precise ratios of macronutrients such as nitrogen, phosphorus, and potassium, alongside essential micronutrients like iron, manganese, and zinc. Achieving ideal growth conditions requires a data-driven approach to nutrient management.

Key components include:

- Macronutrients: N-P-K ratios are calibrated to specific crop requirements, enhancing vegetative and reproductive phases.

- Micronutrients: Trace elements like iron (Fe), manganese (Mn), and zinc (Zn) are meticulously monitored to prevent deficiencies that can impede photosynthesis and enzyme functions.

Such precision guarantees robust plant health and maximizes yield in vertically stacked environments, aligning with innovative agricultural practices.

Balancing Ph Levels

Maintaining ideal pH levels in hydroponic nutrient solutions is essential for guaranteeing nutrient availability and uptake efficiency by the plants. Suitable pH ranges from 5.5 to 6.5, facilitating maximum solubility of macro and micronutrients.

Deviations from this range can precipitate nutrient lockout, impeding plant growth and yield. Precision monitoring using pH meters and automated dosing systems can maintain these parameters within the desired range.

Data from various studies indicate that pH fluctuations greater than 0.5 units can greatly impact nutrient absorption efficiency, specifically for elements like iron and manganese.

Employing buffering agents such as phosphoric acid or potassium hydroxide guarantees rapid correction of pH imbalances, thereby enhancing the vertical hydroponic system's productivity and sustainability.

Light and Climate Control

Effective light and climate control are essential for enhancing plant growth and maximizing yields in vertical hydroponic farming systems.

Advanced LED lighting technologies enable precise spectral tuning, influencing photosynthetic rates and morphogenesis. Meanwhile, climate control systems maintain ideal temperature and humidity levels, vital for plant health and growth efficiency.

Integration of these technologies can lead to:

- Increased Photosynthetic Efficiency: Tailored light spectra improve energy absorption.

- Enhanced Growth Rates: Stable environmental conditions promote faster development.

Utilizing smart sensors and IoT devices allows for real-time monitoring and adjustments, ensuring superior growing conditions.

This data-driven approach minimizes energy inputs while maximizing output, essential for sustainable and scalable vertical farming operations.

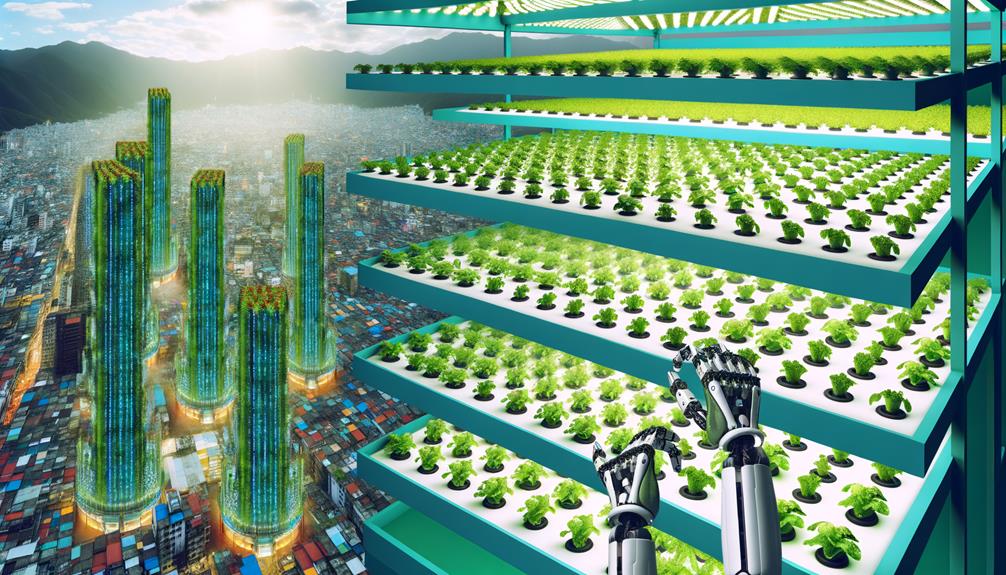

Urban Farming Applications

Leveraging vertical hydroponic systems in urban farming applications addresses the challenges of limited space and resource scarcity, providing a sustainable solution to meet growing food demands.

This approach maximizes vertical space utilization, achieving up to 90% water savings compared to traditional soil-based agriculture. Urban vertical farms can yield approximately 240 times more produce per square meter annually, optimizing photosynthetic efficiency through precision-controlled LED lighting.

Integrating IoT sensors and automated nutrient delivery systems guarantees real-time monitoring and adjustment, enhancing crop quality and growth rates.

By localizing food production, vertical hydroponic farming minimizes transportation emissions and supply chain disruptions, thereby contributing to urban food security and environmental sustainability.

This paradigm shift aligns with contemporary urban planning and smart city initiatives.

Future Trends and Innovations

Building on the success of urban vertical hydroponic farming, future trends and innovations are poised to revolutionize the industry through advancements in automation, genetic engineering, and renewable energy integration. These developments promise to greatly enhance yield efficiency, resource optimization, and sustainability metrics. As technology progresses, aspiring individuals looking to become a hydroponic farmer will have access to smarter systems that require minimal manual intervention while maximizing crop production. Innovations such as AI-driven nutrient monitoring and adaptive LED lighting will further refine growing conditions, ensuring consistent and high-quality yields. With these advancements, urban farming will play a crucial role in addressing food security challenges and reducing the environmental footprint of traditional agriculture.

Key innovations include:

- Automation and AI: Integrating machine learning algorithms for real-time monitoring and predictive maintenance.

- Genetic Engineering: Developing crop varieties engineered for higher nutrient uptake and resistance to pathogens.

These trends are underpinned by rigorous data analysis and cutting-edge technology, ensuring that vertical hydroponic farming continues to evolve and meet the demands of a growing global population.

Conclusion

Vertical hydroponic farming, with its roots in ancient agricultural practices and principles of maximizing space, emerges as a beacon of innovation in modern agriculture.

By stacking plant beds and optimizing nutrient delivery, this method transforms urban landscapes into lush, green towers.

The technology's ability to enhance crop yields, minimize resource use, and adapt to confined spaces paints a vivid picture of a sustainable future.

As advancements in nutrient solutions and climate control continue, vertical hydroponics promises to revolutionize food production.