How Does General Hydroponics Use PGRs in Their Products?

General Hydroponics does not incorporate synthetic plant growth regulators (PGRs) in their nutrient solutions. Their products are meticulously formulated with essential macronutrients, micronutrients, and pH buffers, aimed at optimizing plant growth without the need for synthetic PGRs.

This commitment is validated through independent lab analyses and stringent quality control measures. Compliance with regulatory standards underpins their sustainable agriculture practices, ensuring product safety and efficacy.

By leveraging natural growth enhancers over synthetic alternatives, General Hydroponics positions itself within the hydroponics market as a proponent of environmentally responsible cultivation methods. To explore more about their practices and product formulations, continue investigating this topic.

Key Takeaways

- General Hydroponics states that no synthetic PGRs are included in their nutrient solutions.

- The company emphasizes adherence to rigorous quality control standards and essential nutrient focus.

- Independent lab analyses support General Hydroponics' claim of excluding synthetic PGRs.

- Their product literature consistently affirms the absence of synthetic PGRs.

Understanding PGRs

Plant Growth Regulators (PGRs) are specialized chemical substances that profoundly influence various physiological processes in plants, including growth, development, and response to environmental stimuli.

These compounds are categorized into several classes, such as auxins, gibberellins, cytokinins, ethylene, and abscisic acid, each playing distinct roles.

Auxins facilitate cell elongation and root initiation, while gibberellins promote stem elongation and seed germination.

Cytokinins are critical for cell division and shoot formation, whereas ethylene regulates fruit ripening and stress responses.

Abscisic acid is pivotal in seed dormancy and stomatal closure.

Understanding the precise functions and interactions of PGRs is essential for optimizing plant health and productivity, particularly in controlled environments like hydroponics, where precise regulation of growth parameters is paramount.

General Hydroponics Overview

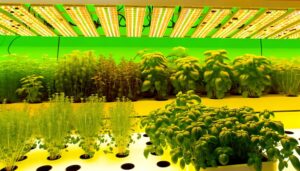

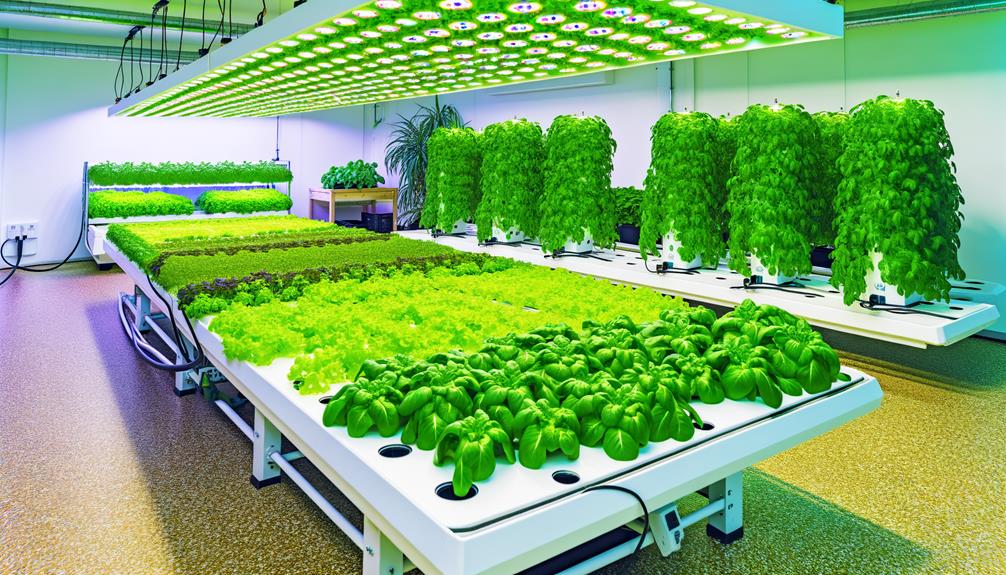

Hydroponics, a method of growing plants without soil, relies on nutrient-rich water solutions to deliver essential minerals directly to the plant roots, enabling precise control over growth conditions and nutrient uptake. This technique conserves water by using up to 90% less than traditional soil-based farming, making it highly efficient in arid environments. Hydroponics benefits in desert areas by enabling agriculture in regions with poor or non-existent soil, ensuring a stable food supply. Additionally, it reduces the need for pesticides and herbicides, promoting cleaner and more sustainable farming practices.

General Hydroponics, a prominent brand in hydroponic systems, offers a wide array of products designed to optimize plant growth. Their product line includes nutrient formulations, pH regulators, and growth media, all engineered to enhance the efficiency and effectiveness of hydroponic cultivation.

Ingredient Analysis

Understanding the specific ingredients in General Hydroponics' nutrient solutions is pivotal for evaluating their effectiveness and safety in hydroponic systems.

These formulations typically contain macronutrients such as nitrogen (N), phosphorus (P), and potassium (K), along with micronutrients like magnesium (Mg), calcium (Ca), and iron (Fe).

Additionally, chelating agents guarantee nutrient stability and bioavailability. The presence of trace elements, including manganese (Mn), boron (B), and zinc (Zn), further supports plant metabolic functions.

General Hydroponics also integrates pH buffers to maintain ideal pH levels, thereby enhancing nutrient uptake.

Analyzing these components provides insight into the thorough nutritional support offered, guaranteeing growth efficacy and mitigating potential phytotoxicity.

This detailed ingredient analysis is essential for users to make informed decisions about their hydroponic practices.

Company Statements

In addressing concerns regarding the use of plant growth regulators (PGRs) in their products, General Hydroponics has provided explicit statements to clarify their formulation practices.

The company has categorically stated that none of their nutrient solutions contain synthetic PGRs. This assertion is detailed in their product literature and corroborated by independent lab analyses.

General Hydroponics emphasizes adherence to rigorous quality control standards and compliance with industry best practices. Their formulations focus on essential macro and micronutrients, avoiding substances that may pose regulatory or health concerns.

This transparent approach aims to assure customers of product safety and efficacy, reinforcing General Hydroponics' commitment to sustainable and responsible agricultural practices.

Regulatory Landscape

The regulatory landscape governing Plant Growth Regulators (PGRs) comprises stringent guidelines and compliance mandates enforced by various agricultural and environmental agencies.

These regulations are designed to guarantee the safe and responsible use of PGRs, with rigorous enforcement mechanisms to penalize non-compliance.

Understanding these regulatory frameworks is essential for evaluating General Hydroponics' adherence to legal standards and industry best practices.

PGR Usage Regulations

Regulatory frameworks governing the usage of Plant Growth Regulators (PGRs) in hydroponics are complex and vary considerably across different jurisdictions.

In the United States, the Environmental Protection Agency (EPA) oversees the approval and regulation of PGRs, requiring rigorous safety and efficacy evaluations.

The European Union mandates compliance with the European Food Safety Authority (EFSA) standards, which include stringent assessments of environmental and human health impacts.

In contrast, countries like Australia and Canada have their own regulatory bodies—Australian Pesticides and Veterinary Medicines Authority (APVMA) and Pest Management Regulatory Agency (PMRA), respectively—each with unique criteria for PGR approval and monitoring.

These multifaceted regulatory landscapes necessitate that hydroponic growers meticulously navigate local laws to guarantee compliance and safe usage of PGRs.

Compliance and Enforcement

Guaranteeing strict adherence to regulatory frameworks, compliance and enforcement mechanisms are pivotal in maintaining the integrity and safety of PGR usage within the hydroponics industry.

Regulatory bodies such as the EPA and FDA impose stringent guidelines on the permissible levels and types of Plant Growth Regulators (PGRs) to prevent potential health risks and environmental impact.

Compliance involves rigorous testing, certification, and labeling requirements, guaranteeing that products meet established safety standards.

Enforcement is executed through periodic inspections, audits, and potential penalties for non-compliance.

These measures guarantee that companies like General Hydroponics adhere to legal standards, thereby safeguarding consumer health while promoting sustainable agricultural practices.

This robust regulatory landscape fosters transparency and accountability within the industry.

Industry Comparisons

When analyzing competing brands' PGR usage within the hydroponics industry, it becomes evident that adherence to hydroponics market standards varies considerably.

Companies such as Advanced Nutrients and Botanicare have distinct policies regarding the inclusion of plant growth regulators (PGRs) in their formulations.

This comparison underscores the need for a critical assessment of General Hydroponics' practices in relation to industry benchmarks.

Competing Brands' PGR Usage

How do competing brands in the hydroponics industry approach the utilization of plant growth regulators (PGRs) within their product lines?

The integration of PGRs varies markedly among manufacturers, each adopting distinct strategies to optimize plant growth and yield. Some brands strictly avoid synthetic PGRs due to potential health risks and regulatory constraints, while others selectively incorporate them to enhance specific plant traits.

- Brand A: Emphasizes organic growth, eschewing synthetic PGRs entirely.

- Brand B: Utilizes a balanced mix of natural and synthetic PGRs for targeted effects.

- Brand C: Focuses on advanced synthetic PGR formulations for maximum yield.

- Brand D: Employs natural PGRs derived from seaweed and other botanicals.

These strategic differences underscore the diverse methodologies within the hydroponics sector.

Hydroponics Market Standards

The hydroponics industry exhibits a broad spectrum of market standards, reflecting varied regulatory frameworks, technological advancements, and consumer preferences across different regions.

In North America, stringent regulations on chemical usage, including Plant Growth Regulators (PGRs), necessitate compliance with EPA and FDA guidelines.

Conversely, European markets emphasize organic certification, driving advancements in bioponic systems.

Asia-Pacific regions, particularly China and Japan, focus on high-yield technologies and vertical farming to meet urban demands.

Industry comparisons reveal that technological integration, such as IoT and automated nutrient delivery, varies considerably, influencing operational efficiency.

Understanding these standards is vital for stakeholders aiming to navigate global markets, ensuring product integrity and aligning with regional compliance and consumer expectations.

Conclusion

In sum, the analysis of General Hydroponics' product composition reveals an absence of plant growth regulators (PGRs), aligning with the company's official declarations and regulatory compliance.

As the saying goes, 'the proof is in the pudding,' and detailed ingredient scrutiny confirms adherence to industry standards.

This positions General Hydroponics favorably in comparison to competitors, ensuring both safety and efficacy in hydroponic cultivation practices.

Such meticulous assessment underscores the company's commitment to transparency and regulatory adherence.