10 Steps to Build a Recirculating Hydroponic System

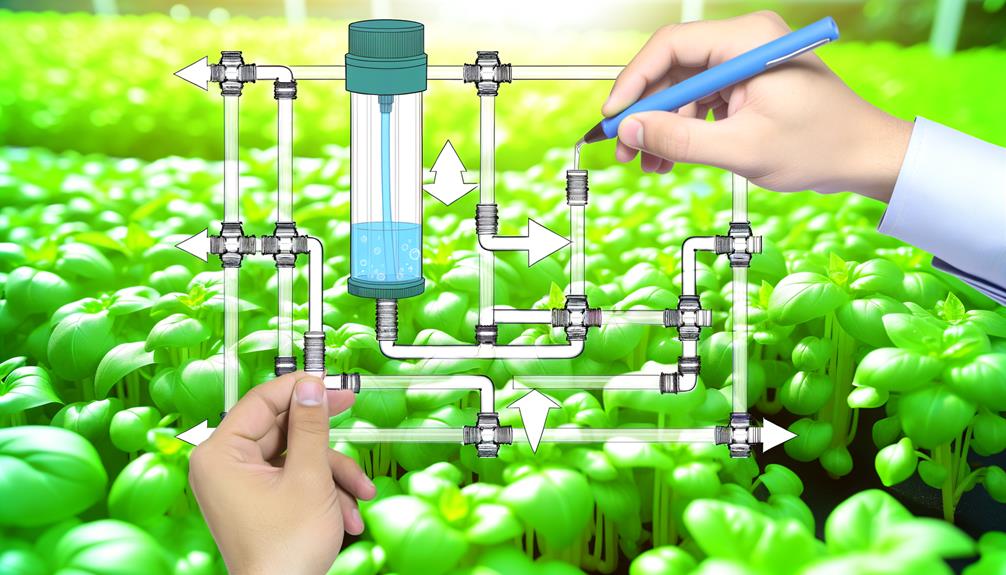

Building a recirculating hydroponic system involves setting up a closed-loop system where nutrient-rich water is continuously cycled through the plant roots, maximizing nutrient uptake and growth. Start with a food-grade plastic reservoir, a submersible pump of adequate capacity, and PVC pipes for nutrient delivery.

Construct a stable, precise framework using treated lumber and guarantee all connections are secure. Install the reservoir with an inert, opaque container to avoid contamination and algae growth.

Connect the pump and tubing, ensuring secure fittings to prevent leaks. For further guidance on maintaining your system for ideal plant health and productivity, continue exploring.

Key Takeaways

- Choose food-grade plastic for the reservoir to avoid chemical leaching.

- Select a submersible pump with adequate capacity to maintain consistent nutrient flow.

- Use PVC pipes and secure fittings to ensure leak-proof nutrient delivery.

- Build a stable and level framework using treated lumber for structural integrity.

Understanding Recirculating Systems

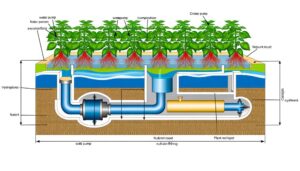

In a recirculating hydroponic system, nutrient-rich water is continuously cycled through plant roots, ensuring efficient nutrient uptake and water use. This method maximizes resource efficiency by maintaining a closed-loop system where nutrients are not wasted but reused.

The core components include a reservoir, a pump, and a series of channels or grow beds where plants are housed. The pump circulates the nutrient solution from the reservoir through the plant roots and back, maintaining ideal nutrient levels and oxygenation.

This dynamic flow system prevents nutrient stagnation and enhances plant growth rates. By precisely controlling the nutrient mixture and water pH, recirculating systems provide a versatile and sustainable solution for modern agricultural practices, fostering innovation in crop production.

Gathering Your Materials

Acquiring the necessary materials is a critical step in constructing an efficient and effective hydroponic system. This includes selecting high-quality growing mediums, nutrient solutions, and appropriate containers to support plant growth. Choosing the best DIY hydroponic system ensures optimal water and nutrient delivery, leading to healthier plants and higher yields. Additionally, proper lighting and ventilation play a crucial role in maintaining the ideal growing environment.

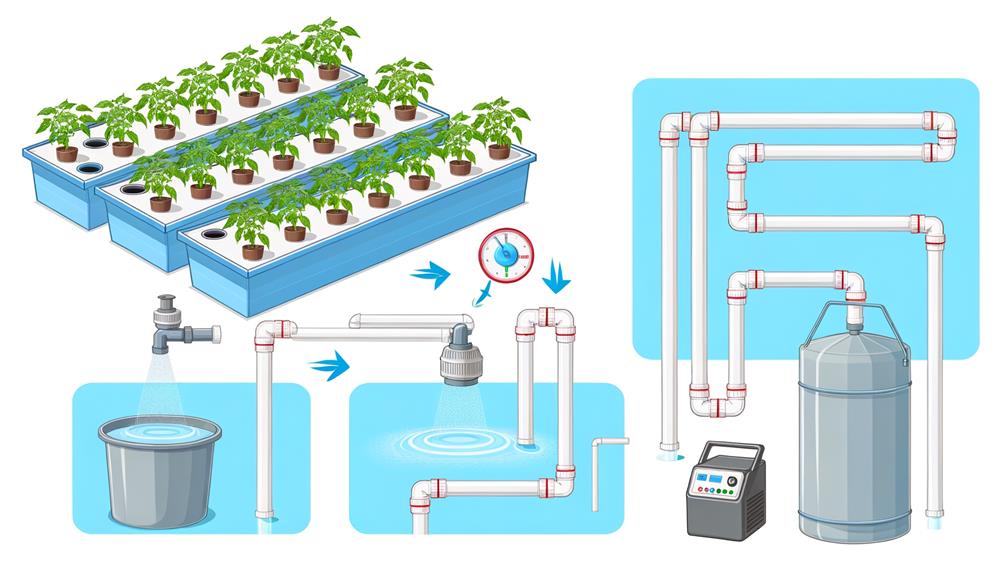

Begin with a reservoir, preferably a food-grade plastic container to avoid chemical leaching.

Next, secure a submersible pump with sufficient capacity for your system's size.

Obtain PVC pipes for nutrient delivery, making certain they are correctly sized and compatible with your pump.

Essential fittings include elbows, tees, and end caps.

Purchase high-quality grow trays, net pots, and a reliable air pump paired with air stones for oxygenation.

Nutrient solutions formulated specifically for hydroponics are imperative.

Finally, invest in a pH meter and an EC meter to monitor nutrient solution parameters precisely.

These components collectively guarantee ideal plant growth and system functionality.

Constructing the Framework

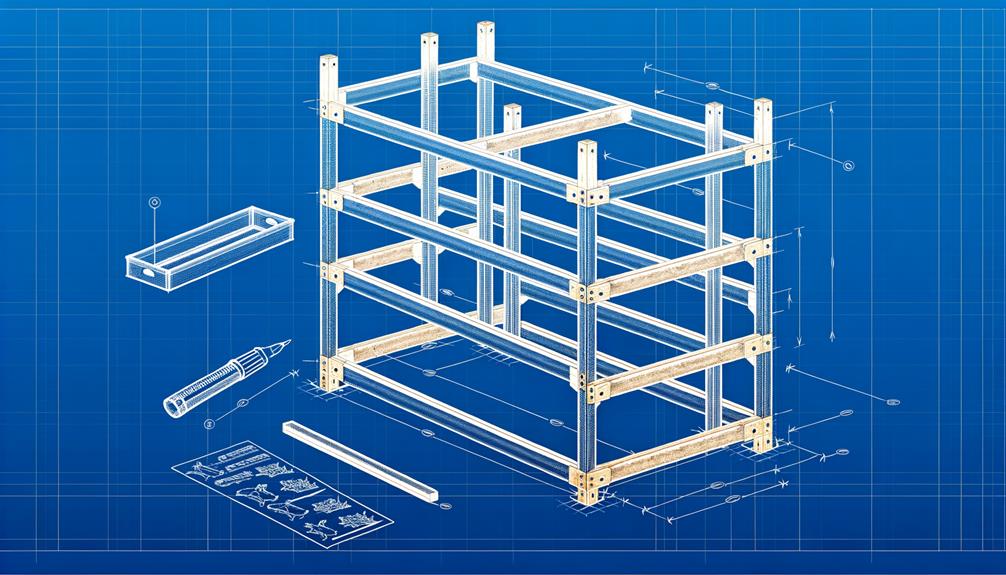

To begin constructing the framework, secure a stable base for your hydroponic system to guarantee proper support and alignment. Utilize robust materials such as treated lumber or sturdy metal to form the base, making sure it is level and capable of bearing the system's weight.

Precision in measurement is essential; use a spirit level to confirm horizontal alignment. Next, install the vertical supports, making certain they are perpendicular to the base. These supports will hold the growing containers and facilitate ideal nutrient flow.

Attach cross beams to connect the vertical supports, creating a rigid structure. Confirm all joints are tightly fastened using appropriate connectors, such as brackets and screws, to prevent any structural weaknesses.

This guarantees longevity and reliability in your hydroponic system.

Setting Up the Reservoir

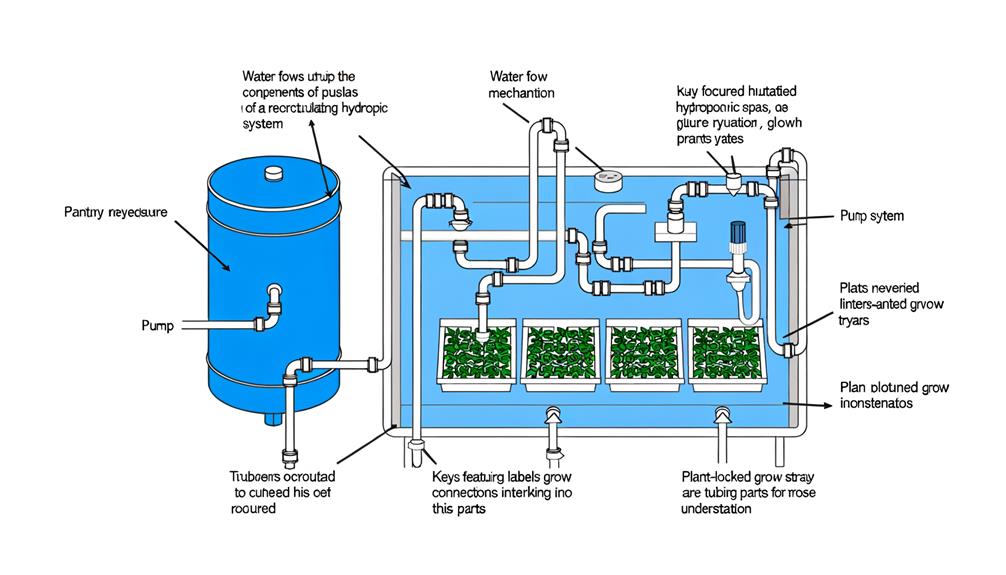

Selecting an appropriate reservoir is essential for ensuring a consistent and reliable supply of nutrient solution to your hydroponic system. The reservoir's material must be inert to avoid chemical reactions with the nutrient solution. Opt for opaque containers to minimize algae growth. The size should match the system's demands, ensuring adequate capacity for nutrient solution and buffer volume.

| Material | Characteristics |

|---|---|

| Plastic | Lightweight, non-reactive |

| Stainless Steel | Durable, non-corrosive |

| Glass | Inert, but fragile |

| Food-grade Polyethylene | Safe, cost-effective |

Ensure the reservoir is equipped with a secure lid to prevent contamination. Regular monitoring of the solution's pH and EC (Electrical Conductivity) is vital for ideal plant growth. Maintain a stable temperature to protect nutrient integrity.

Installing the Pump and Tubing

To guarantee efficient nutrient delivery in your hydroponic system, start by selecting a pump with the appropriate flow rate and pressure for your setup.

Once the pump is chosen, securely connect the tubing to prevent leaks and maintain a consistent flow.

Proper installation of these components is essential for system reliability and plant health.

Choosing Pump Specifications

Determining the appropriate pump specifications is essential for guaranteeing ideal water flow and nutrient distribution in your hydroponic system.

Begin by calculating the total volume of your reservoir and the required flow rate, typically measured in gallons per hour (GPH). A general rule of thumb is to have the entire reservoir volume recirculated every 1-2 hours.

Additionally, consider the head height, the vertical distance the pump must move water, as it directly affects pump efficiency.

Opt for submersible pumps for smaller systems due to their compact design and ease of maintenance. For larger setups, inline pumps offer enhanced power and scalability.

Verify the pump's material is resistant to corrosion and safe for nutrient solutions to maintain system integrity.

Connecting Tubing Securely

Once you have chosen the appropriate pump, the next step is to install it and connect the tubing securely to guarantee consistent water flow and nutrient delivery in your hydroponic system.

Start by positioning the pump at the lowest point of your reservoir to maximize water intake.

Next, cut the tubing to the required length, making sure of a snug fit to prevent leaks.

Finally, use hose clamps to secure the tubing connections to the pump and grow bed.

- Position the Pump: Place it at the reservoir's base for maximum water intake.

- Cut Tubing: Measure and cut to make sure of a tight, leak-proof fit.

- Secure Connections: Use hose clamps to firmly attach tubing to the pump and grow bed.

These steps will guarantee a robust and efficient hydroponic system.

Maintaining Your Hydroponic System

Maintaining your hydroponic system requires vigilant nutrient solution monitoring and regular cleaning and sterilization.

Accurate monitoring of pH and nutrient levels is essential to guarantee ideal plant growth and prevent deficiencies.

Additionally, routine cleaning and sterilization of all system components help prevent contamination and disease outbreaks, thereby securing the longevity of your system.

Nutrient Solution Monitoring

Accurate monitoring of the nutrient solution is essential to guarantee suitable growth and health of plants in a hydroponic system. This precision guarantees that plants receive the ideal balance of nutrients required.

Key aspects of nutrient solution monitoring include:

- pH Levels: Regularly measure the pH to maintain it within the ideal range of 5.5 to 6.5. This range maximizes nutrient uptake.

- Electrical Conductivity (EC): Monitor EC to gauge the concentration of nutrients. An appropriate EC value varies but generally lies between 1.0 to 2.5 mS/cm.

- Temperature: Keep the nutrient solution temperature between 65°F and 75°F to prevent root shock and guarantee efficient nutrient absorption.

Consistent monitoring and adjustments based on these parameters will sustain a robust hydroponic system.

Cleaning and Sterilization

To guarantee peak performance and longevity of your hydroponic system, regular cleaning and sterilization of all components are imperative.

Begin by draining the nutrient solution and disassembling the system. Use a 10% bleach solution or hydrogen peroxide to sterilize reservoirs, tubing, and grow trays. Confirm thorough rinsing with clean water to remove any residual chemicals.

Scrub surfaces with a soft brush to eliminate buildup and prevent microbial contamination. Pay special attention to pumps and filters, as they are prone to clogging.

Implement a routine cleaning schedule, ideally between crop cycles, to maintain an ideal growing environment.

This meticulous maintenance not only prevents disease but also enhances nutrient uptake efficiency, confirming robust plant health and consistent yields.

Conclusion

In summary, constructing a recirculating hydroponic system requires meticulous planning and precise execution, akin to orchestrating a symphony where each component plays a critical role.

By understanding the system's intricacies, gathering appropriate materials, building a stable framework, properly setting up the reservoir, and guaranteeing efficient pump and tubing installation, one can achieve a harmonious balance that promotes ideal plant growth.

Regular maintenance is essential to sustain this balance and guarantee the system's longevity and productivity.