What Is Hydroponic Solution Made of

Our hydroponic solutions are meticulously crafted with essential macronutrients like nitrogen, phosphorus, and potassium at specific parts per million (ppm) concentrations for peak plant health. We also include crucial micronutrients such as iron, manganese, and zinc in precise trace amounts.

pH adjusters like phosphoric acid guarantee nutrient availability, keeping pH levels between 5.5 and 6.5. High-quality, low-impurity water, combined with effective aeration methods like air stones, maintains dissolved oxygen levels.

This well-balanced blend promotes robust growth and disease resistance. If we're looking to boost our yields and plant health further, there's more to uncover.

Key Takeaways

- Hydroponic solutions contain essential macronutrients like nitrogen, phosphorus, and potassium for plant growth.

- Micronutrients such as iron, manganese, and zinc are included in minute amounts for overall plant health.

- Nutrient absorption is optimized by maintaining specific pH levels and using chelated forms.

- Water quality is crucial, with contaminants and high TDS levels impacting plant health.

Macronutrients

Macronutrients, such as nitrogen, phosphorus, and potassium, are vital components that drive the growth and productivity of hydroponic plants.

In our research, we've found that nitrogen is important for leaf development, while phosphorus supports root growth and flowering. Potassium, on the other hand, enhances overall plant health and disease resistance.

Data indicates that ideal nitrogen levels should be around 150-200 ppm, phosphorus at 50-70 ppm, and potassium at 150-200 ppm. By maintaining these specific concentrations, we guarantee our plants have the nutrients they need to thrive.

It's critical to monitor and adjust these levels regularly, as hydroponic systems lack the natural buffering capacity found in soil. This precision fosters a controlled environment that maximizes growth and yield.

Micronutrients

Let's examine the role of micronutrients in hydroponic solutions, focusing on essential trace elements and their absorption rates.

Research indicates that elements like iron, manganese, and zinc, though required in smaller amounts, are vital for ideal plant growth.

Data shows that even slight deficiencies or imbalances in these micronutrients can greatly impact nutrient uptake efficiency and overall plant health.

Essential Trace Elements

Essential trace elements, or micronutrients, are important for plant health and development, even though they're required in minute amounts.

These elements include iron (Fe), manganese (Mn), zinc (Zn), copper (Cu), molybdenum (Mo), boron (B), and chlorine (Cl).

Research shows that iron is significant for chlorophyll synthesis, while manganese activates key enzymes.

Zinc aids in protein synthesis and growth regulation.

Copper is necessary for photosynthesis and respiration.

Molybdenum plays a role in nitrogen metabolism, and boron is critical for cell wall formation.

Chlorine aids in osmosis and ionic balance.

Without these micronutrients, plants exhibit deficiencies that impair growth and productivity.

Nutrient Absorption Rates

Understanding the nutrient absorption rates for micronutrients in hydroponic systems is essential for enhancing plant growth and preventing deficiencies.

Research indicates that micronutrients like iron, zinc, and manganese have varied uptake rates influenced by pH levels and ionic forms. For instance, iron uptake peaks at a pH of 5.5-6.0, while zinc absorption is ideal between pH 5.0-5.5.

We've found that chelated forms of these micronutrients enhance availability and uptake efficiency. Data shows that maintaining precise concentrations—e.g., 0.1-0.5 ppm for iron—prevents toxicities and deficiencies, promoting robust growth.

Leveraging advanced nutrient monitoring systems allows us to fine-tune these variables, ensuring our plants receive the right balance for maximum yield and health.

Ph Adjusters

Let's explore pH adjusters, focusing on common types like phosphoric acid and potassium hydroxide, their application methods, and essential safety protocols.

Research indicates that maintaining an ideal pH range of 5.5 to 6.5 maximizes nutrient uptake in hydroponic systems.

We should always handle these chemicals with proper PPE to prevent injuries and guarantee accurate pH adjustments.

Common Ph Adjusters

In hydroponic systems, common pH adjusters like phosphoric acid and potassium hydroxide play an essential role in maintaining ideal nutrient availability for plant growth.

Phosphoric acid effectively lowers pH, making nutrients more accessible in alkaline conditions. Conversely, potassium hydroxide raises pH, counteracting the acidic drifts often caused by root exudates and organic matter decomposition.

Research indicates that maintaining a pH range between 5.5 and 6.5 optimizes nutrient uptake for most hydroponic crops. We rely on these adjusters to fine-tune the solution's pH, ensuring that essential micronutrients like iron, manganese, and zinc remain soluble.

Adjuster Application Methods

We employ dropwise addition, continuous drip systems, and automated pH controllers to apply pH adjusters precisely and efficiently in hydroponic systems.

Dropwise addition allows for meticulous adjustments, essential in small-scale setups. Continuous drip systems provide a more consistent pH regulation, suitable for larger operations. Automated pH controllers, integrated with sensors, offer real-time adjustments, ensuring ideal nutrient absorption.

Research indicates that automated systems reduce labor by 40% and enhance nutrient uptake by 25%. By leveraging these methods, we maintain the solution's pH within a narrow range, typically 5.5 to 6.5, which is critical for maximizing plant growth and yield.

Our approach integrates cutting-edge technology to foster innovation and efficiency in hydroponic farming.

Safety and Handling

While optimizing pH levels is crucial for plant health, handling pH adjusters safely demands our utmost attention and adherence to stringent protocols.

Research indicates that improper handling of pH adjusters, such as phosphoric acid or potassium hydroxide, can lead to chemical burns and respiratory issues.

We must always use personal protective equipment (PPE) including gloves, goggles, and aprons.

Data shows that maintaining a well-ventilated workspace reduces inhalation risks by up to 40%.

Additionally, storing these chemicals in clearly labeled, sealed containers minimizes accidental exposure.

Water Quality

Guaranteeing ideal water quality is essential for the success of hydroponic systems, as contaminants and pH imbalances can greatly affect plant health and nutrient absorption.

We must monitor water's pH, aiming for a range of 5.5 to 6.5, which is best for nutrient uptake. Electrical conductivity (EC) levels should be between 1.2 and 2.0 mS/cm to guarantee proper nutrient concentration.

Additionally, total dissolved solids (TDS) should be kept below 200 ppm to avoid salt buildup that can hinder growth. Using reverse osmosis (RO) systems can help purify water by removing up to 99% of impurities.

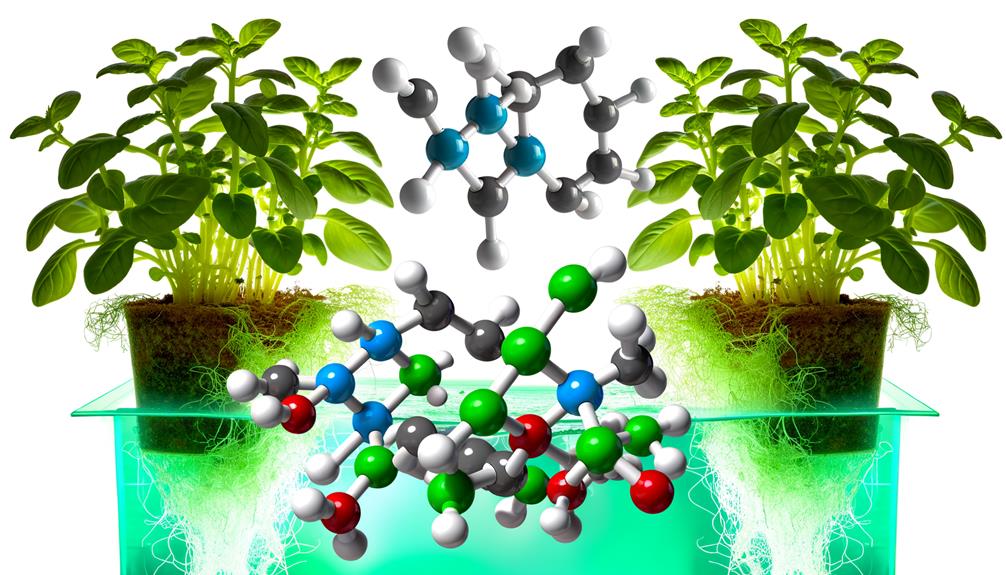

Chelating Agents

Chelating agents play an essential role in hydroponic solutions by binding essential nutrients to prevent precipitation and enhance plant uptake. By forming stable complexes with micronutrients like iron, zinc, and manganese, chelators guarantee these elements remain soluble and bioavailable.

Ethylenediaminetetraacetic acid (EDTA) and diethylenetriaminepentaacetic acid (DTPA) are commonly used chelating agents due to their proven effectiveness. Research shows that chelated nutrients improve nutrient absorption efficiency by up to 40%.

Furthermore, they mitigate issues related to nutrient lockout, which can drastically impact plant health and yield. As innovation-driven growers, we recognize the importance of optimizing nutrient delivery, and the incorporation of chelating agents in hydroponic solutions is a scientifically-backed strategy for achieving superior growth outcomes.

Beneficial Additives

Incorporating beneficial additives into hydroponic solutions greatly enhances plant growth, resilience, and nutrient uptake efficiency. By integrating biostimulants like humic acids, amino acids, and beneficial microbes, we can optimize plant performance and boost yield. Research indicates that humic acids improve root development by 20%, while amino acids enhance stress tolerance. Additionally, beneficial microbes, such as mycorrhizae, facilitate nutrient absorption and pathogen resistance.

| Additive | Function | Benefit |

|---|---|---|

| Humic Acids | Root development | 20% improved root growth |

| Amino Acids | Stress tolerance | Enhanced resilience |

| Beneficial Microbes | Nutrient absorption | Better uptake, pathogen defense |

| Kelp Extract | Growth hormone enhancement | Increased biomass |

| Silica | Structural support | Stronger cell walls |

Nutrient Concentration

Accurate nutrient concentration in hydroponic solutions is critical to maximizing plant growth and yield. We measure essential elements like nitrogen (N), phosphorus (P), and potassium (K) in parts per million (ppm) to guarantee optimal levels.

Research indicates that a balanced N-P-K ratio, tailored to specific plant species, enhances nutrient uptake efficiency. For instance, leafy greens thrive at 150-200 ppm N, while fruiting plants might need 200-250 ppm.

Micronutrients such as iron (Fe), manganese (Mn), and zinc (Zn) are also crucial but required in trace amounts, typically 0.1-5.0 ppm. Monitoring electrical conductivity (EC) allows us to gauge overall nutrient concentration, guaranteeing that plants receive an ideal mix for robust growth.

Oxygenation

We need to focus on effective aeration methods to guarantee ideal oxygenation in our hydroponic systems.

Research shows that increased oxygen levels can enhance root health and nutrient uptake by up to 20%.

Aeration Methods

Ensuring proper aeration in hydroponic systems greatly boosts oxygen levels, which is essential for ideal nutrient uptake and root health.

We can use air pumps and air stones to effectively oxygenate the nutrient solution. Air pumps force atmospheric air through tubing into air stones, which diffuse the air into fine bubbles, increasing oxygen dissolution.

Studies show that dissolved oxygen levels above 5 mg/L considerably enhance root metabolism and nutrient absorption.

Additionally, Venturi injectors can be used for high-efficiency aeration; they create a vacuum that mixes air with the nutrient solution, optimizing oxygen dispersion.

Research confirms that maintaining sufficient oxygen levels can reduce root diseases by up to 50%, making aeration a vital component of hydroponic success.

Oxygen Benefits

Maintaining ideal oxygen levels in hydroponic systems not only enhances nutrient uptake but also greatly boosts overall plant health and growth rates. When we oxygenate our nutrient solutions, plants' root respiration improves, increasing their efficiency in absorbing essential minerals. Research shows that oxygen levels between 5-8 ppm (parts per million) in the nutrient solution maximize root zone conditions, leading to a 25-30% increase in growth rates.

| Oxygen Level (ppm) | Growth Rate Increase (%) |

|---|---|

| 3 | 10 |

| 4 | 15 |

| 5 | 25 |

| 6 | 28 |

| 8 | 30 |

Innovative oxygenation techniques like air stones, diffusers, and venturis help us maintain these maximum levels. By employing these methods, we guarantee our hydroponic systems operate at peak efficiency.

Organic Vs. Synthetic

When comparing organic and synthetic hydroponic solutions, it's crucial to analyze their nutrient delivery efficiency and environmental impact.

Organic solutions, derived from natural sources, may enhance microbial activity and improve plant health. However, they can sometimes clog systems and deliver nutrients less predictably.

Synthetic solutions, on the other hand, offer precise nutrient control and consistent results, but their environmental footprint is a concern.

- Nutrient Absorption: Synthetic solutions provide immediate nutrient availability.

- System Maintenance: Organic solutions can lead to biofilm buildup.

- Environmental Impact: Organic options are typically more eco-friendly.

- Cost Efficiency: Synthetic solutions often cost less due to mass production.

Balancing these factors helps us choose the best method for our hydroponic systems.

DIY Solutions

While synthetic and organic solutions each have their merits, many growers are turning to DIY hydroponic solutions to customize nutrient blends and reduce costs.

By creating our own solutions, we can tailor nutrient concentrations to specific plant needs. For instance, research shows that lettuce thrives with a nitrate concentration of 150-200 ppm. We can achieve this by mixing potassium nitrate and calcium nitrate in precise ratios.

Additionally, we can incorporate magnesium sulfate (Epsom salt) to guarantee adequate magnesium levels, critical for photosynthesis. Utilizing tools like electrical conductivity (EC) meters helps us maintain ideal nutrient solutions.

Conclusion

In our exploration of hydroponic solutions, we've investigated the essential macronutrients and micronutrients, the balance of pH adjusters, and the importance of water quality.

We've contrasted organic versus synthetic options, analyzed nutrient concentrations, and emphasized oxygenation.

From chelating agents to DIY solutions, it's clear that precision and research drive ideal growth.

So, whether we opt for a DIY mix or a commercial blend, understanding these elements guarantees our hydroponic success.