How to Grow Watercress Hydroponically – A Step-by-Step Guide

Yes, watercress can be grown hydroponically. Utilizing controlled nutrient solutions and enhanced environmental parameters boosts growth dynamics and yield potential (Resh, 2013).

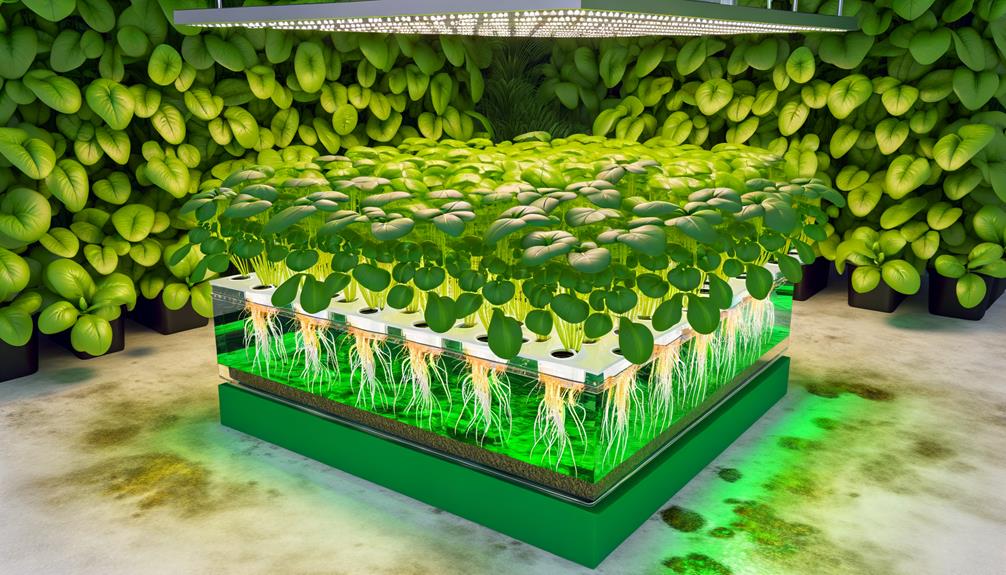

Hydroponic systems such as Nutrient Film Technique (NFT) and Deep Water Culture (DWC) provide effective platforms for watercress cultivation, minimizing soil-borne disease risks like Pythium spp. (Stanghellini & Rasmussen, 1994), and enabling high-density, year-round production.

Essential equipment includes grow lights, nutrient reservoirs, and pH meters (Jones, 2005). Maintaining ideal conditions such as 10-20°C temperature, 60-70% relative humidity, and precise nutrient balance guarantees robust growth.

For further exploration of hydroponic watercress, more specialized details await.

Key Takeaways

- Watercress can be effectively grown hydroponically using systems like NFT, DWC, or Aeroponics.

- Hydroponic cultivation accelerates watercress growth and increases yield potential.

- Growing watercress hydroponically eliminates soil-borne disease risks.

- Hydroponic systems allow for high-density, year-round watercress production.

Benefits of Hydroponic Watercress

Hydroponic watercress cultivation offers numerous advantages, including optimized nutrient delivery, enhanced growth rates, and reduced risk of soil-borne diseases.

By utilizing a controlled nutrient solution, watercress plants receive precise concentrations of essential minerals, facilitating superior growth dynamics (Resh, 2013). Enhanced nutrient uptake efficiency results in accelerated biomass accumulation and increased yield potential.

Furthermore, the elimination of soil as a growing medium mitigates the risk of pathogens such as Pythium spp., which are notorious for causing root rot (Stanghellini & Rasmussen, 1994).

Additionally, hydroponic systems allow for the fine-tuning of environmental parameters such as pH, electrical conductivity, and oxygen levels, further augmenting plant health and productivity.

These systems offer a robust framework for high-density, year-round watercress production, meeting both commercial and research needs.

Choosing the Right System

When selecting an appropriate hydroponic system for cultivating watercress, it is essential to evaluate various types such as Nutrient Film Technique (NFT), Deep Water Culture (DWC), and aeroponics, each offering distinct advantages in nutrient delivery and root aeration (Resh, 2012).

System space requirements must be assessed to guarantee adequate growth area and efficient use of available resources (Jensen, 1997).

Additionally, a thorough cost-benefit analysis considering initial setup, operational costs, and maintenance demands will inform the most economically and logistically viable choice (Jones, 2005).

Types of Hydroponic Systems

Selecting the appropriate hydroponic system for cultivating watercress requires an extensive understanding of the various system types, including Nutrient Film Technique (NFT), Deep Water Culture (DWC), and aeroponics. Each of these systems offers distinct advantages and limitations based on factors like space, budget, and maintenance requirements.

NFT, characterized by a thin film of nutrient solution flowing over the roots, is efficient for small-scale setups but demands precise monitoring to prevent root desiccation.

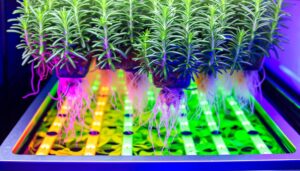

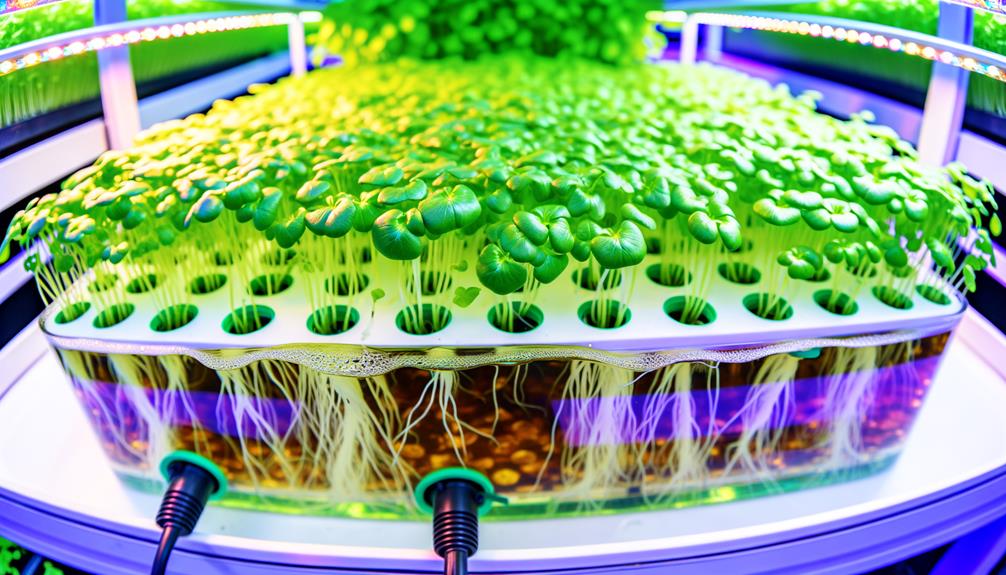

DWC, where plants are suspended with roots submerged in oxygenated nutrient solution, offers simplicity and robustness, making it ideal for beginners.

Aeroponics, which involves misting roots with nutrient solutions, maximizes oxygen exposure and growth rates. However, it comes with higher initial costs and technical complexity (Jones, 2016).

Ultimately, each system's selection should align with specific cultivation goals.

System Space Requirements

Understanding the spatial requirements of different hydroponic systems is essential to guaranteeing ideal watercress growth, as each system demands specific space configurations that impact both plant health and yield efficiency.

For instance, Vertical Farming Systems (VFS) maximize vertical space, allowing higher plant density per square meter, which is vital in urban agriculture (Despommier, 2010).

Conversely, Deep Water Culture (DWC) systems necessitate expansive horizontal space to accommodate water reservoirs and oxygenation devices, important for root health (Resh, 2013).

Nutrient Film Technique (NFT) systems offer a balanced approach, requiring moderate horizontal and vertical space but require precise channel placement to guarantee nutrient flow consistency (Jones, 2016).

Selecting the right system is thus essential to maximizing spatial efficiency and achieving ideal watercress productivity.

Cost and Maintenance

The cost and maintenance requirements of hydroponic systems for growing watercress vary greatly, with each system presenting distinct financial outlays and upkeep demands that influence long-term sustainability and productivity.

Nutrient film technique (NFT) systems, for instance, demand moderate initial investments but offer ease of maintenance due to minimal water usage and efficient nutrient delivery (Resh, 2012).

Conversely, deep water culture (DWC) systems, while cheaper to set up, necessitate constant aeration and vigilant monitoring to prevent root diseases (Jones, 2005).

Aeroponic systems, though technologically advanced and highly efficient, involve significant upfront costs and complex maintenance protocols, including frequent cleaning to avoid nozzle blockages (Jensen & Collins, 1985).

Ultimately, selecting the right system hinges on balancing initial expenditures with ongoing maintenance commitments.

Essential Equipment

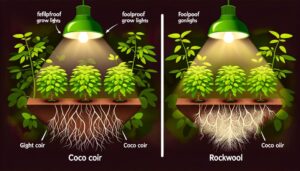

A thorough hydroponic system for growing watercress necessitates specific equipment such as grow lights, nutrient reservoirs, and pH meters to guarantee ideal plant health and productivity.

High-intensity discharge (HID) or LED grow lights are essential to simulate optimal light conditions, promoting vigorous growth (Massa et al., 2008).

Nutrient reservoirs must be equipped with precise dosing systems to deliver a balanced nutrient solution, ensuring the availability of essential macro and micronutrients (Jones, 2005).

pH meters are vital for maintaining the nutrient solution within the ideal pH range of 6.0 to 6.5, critical for nutrient uptake efficiency (Adams, 2004).

Implementing automated monitoring systems can further enhance precision and reduce labor, fostering an innovative approach to hydroponic watercress cultivation.

Ideal Growing Conditions

Ideal hydroponic cultivation of watercress demands meticulous control of environmental parameters, including temperature, humidity, and light intensity, to replicate the plant's natural growing conditions (Resh, 2013). Maintaining ideal conditions is essential for maximizing growth and yield.

Key parameters include:

- Temperature: Watercress thrives at temperatures between 10-20°C (van Os, 1999). Extreme temperatures can inhibit growth and affect nutrient uptake.

- Humidity: Ideal relative humidity levels range from 60-70% to prevent desiccation and promote healthy leaf development (Jensen, 2001).

- Light Intensity: Adequate light is vital; a photoperiod of 12-16 hours with an intensity of 300-400 µmol/m²/s is recommended (Sonneveld and Voogt, 2009).

Achieving these conditions guarantees robust watercress cultivation in hydroponic systems.

Nutrient Solutions

To complement the ideal environmental conditions, precise formulation and management of nutrient solutions are critical in hydroponic watercress cultivation.

Essential macro-nutrients like nitrogen (N), phosphorus (P), and potassium (K) should be meticulously balanced alongside micro-nutrients such as iron (Fe), manganese (Mn), and zinc (Zn) (Resh, 2013).

The best electrical conductivity (EC) range for watercress is between 1.2 to 2.4 mS/cm, ensuring nutrient availability without causing phytotoxicity (Jones, 2005).

pH levels must be tightly regulated between 6.0 and 6.5 to maximize nutrient uptake efficiency (Sonneveld & Voogt, 2009).

Advanced nutrient solution techniques, such as fertigation and real-time monitoring systems, foster precise nutrient delivery, thereby enhancing growth rates and phytochemical content (Gruda, 2009).

Harvesting and Maintenance

Implementing strategic harvesting techniques and routine maintenance protocols are pivotal for sustaining peak growth and maximizing yield in hydroponic watercress cultivation. Regularly harvesting watercress not only stimulates continual growth but also mitigates overcrowding, which can hinder photosynthetic efficiency.

To optimize productivity, consider the following:

- Harvest Frequency: Harvest every 1-2 weeks to encourage regrowth and prevent nutrient depletion.

- Trimming Techniques: Employ precision cutting tools to trim 2-3 inches above the base, ensuring minimal damage to plant structures.

- System Maintenance: Conduct weekly inspections of the hydroponic system, checking pH levels (optimal range: 6.0-6.5), nutrient concentration, and root health (Adams, 2020).

These practices foster a robust growth environment, ensuring high-quality watercress production.

Conclusion

In summary, cultivating watercress hydroponically reveals a verdant tapestry of advantages, ranging from optimized growth conditions to sustainable resource management.

By meticulously selecting the appropriate system and equipment, adhering to ideal growing parameters, and administering precise nutrient solutions, one can achieve a flourishing yield.

This method not only elevates the quality of watercress but also underscores the potential of hydroponics as a beacon for innovative agricultural practices.

The harvest, therefore, becomes a demonstration of the symbiosis of technology and nature.