Why Is My Hydroponic Lettuce Limp

Our hydroponic lettuce can become limp due to issues like nutrient imbalances, less-than-ideal water quality, and environmental stressors. Ensuring precise nutrient ratios, maintaining pH levels between 5.8 and 6.5, and controlling electrical conductivity is essential for best growth.

Water temperature should stay within 65-70°F for maximum nutrient solubility, and robust oxygenation helps prevent root hypoxia. Additionally, proper light conditions and stable temperatures support healthy photosynthesis and growth.

Regularly monitoring and adjusting these factors can keep our lettuce crisp and vibrant. For a thorough look at managing these conditions, there's more to explore on each aspect.

Key Takeaways

- Nutrient imbalances, particularly deficiencies in essential elements, can cause limp lettuce.

- Improper pH levels outside the range of 5.8 to 6.5 can lead to nutrient lockout and limp plants.

- Insufficient oxygen levels in the water can result in root hypoxia, causing limp lettuce.

- Inadequate light conditions, either too little or excessive light, can weaken lettuce, making it limp.

Nutrient Imbalances

Nutrient imbalances in hydroponic lettuce systems often result from incorrect ratios of essential macronutrients and micronutrients, leading to stunted growth and nutrient deficiencies.

We must guarantee that our nutrient solution contains the proper concentrations of nitrogen, phosphorus, potassium, calcium, magnesium, and sulfur, alongside trace elements like iron, manganese, zinc, boron, copper, and molybdenum.

Any deviation can disrupt cellular processes, impair photosynthesis, and reduce chlorophyll production.

By regularly testing the nutrient solution using an EC meter and adjusting based on precise nutrient formulations, we can maintain the ideal nutrient environment.

Additionally, employing chelated forms of micronutrients can enhance uptake efficiency.

Let's prioritize balanced nutrient profiles to maximize lettuce growth and innovation in our hydroponic systems.

Water Quality

When considering water quality, we must guarantee the pH levels are meticulously maintained, as lettuce thrives in a specific range of 5.8 to 6.5.

It's essential that our water supply remains contaminant-free, preventing harmful pathogens and chemicals from disrupting plant growth.

Additionally, we need to maintain a precise nutrient balance to optimize lettuce health and yield.

Ph Levels Matter

Maintaining ideal pH levels is essential for guaranteeing the water quality in hydroponic systems, as it directly affects nutrient availability and lettuce growth.

In hydroponics, the best pH range is typically between 5.5 and 6.5. Deviations can lead to nutrient lockout, where essential minerals become inaccessible to the plants. When pH levels are too high or too low, the solubility of key nutrients like nitrogen, phosphorus, and potassium is compromised.

We must regularly monitor and adjust the pH using pH up or down solutions to maintain this critical balance. Accurate pH management guarantees robust root health, efficient nutrient uptake, and ultimately, crisp, healthy lettuce.

Contaminant-Free Supply

Guaranteeing a contaminant-free water supply is paramount in hydroponic systems, as impurities can disrupt nutrient absorption and compromise lettuce health.

We must utilize reverse osmosis or deionization techniques to eliminate dissolved solids, heavy metals, and pathogens.

Regularly testing for total dissolved solids (TDS) and electrical conductivity (EC) helps us maintain ideal purity.

Chlorine and chloramine, common in tap water, can adversely affect root systems; therefore, we recommend activated carbon filtration.

Additionally, microbial contaminants like Pythium spp. can cause damping-off disease; UV sterilization or ozonation can mitigate this risk.

Nutrient Balance Essentials

Achieving ideal nutrient balance in hydroponic lettuce cultivation demands precise control over water quality parameters, such as pH levels and nutrient concentrations.

We need to monitor pH meticulously, guaranteeing it remains within the optimal range of 5.5 to 6.5. Deviations can hinder nutrient uptake, resulting in limp, undernourished lettuce.

Regarding nutrient concentrations, maintaining the electrical conductivity (EC) between 1.0 and 1.4 mS/cm is essential. Excessive or insufficient EC levels can cause nutrient imbalances, stressing the plants.

Additionally, water temperature should be regulated, ideally between 65°F and 70°F, to maximize nutrient solubility and prevent root diseases.

Ph Levels

In hydroponic lettuce systems, maintaining the ideal pH range of 5.5 to 6.5 is essential for nutrient uptake and plant health.

We need to regularly test the pH levels using calibrated meters and adjust them with pH up or down solutions.

Consistent monitoring and precise adjustments guarantee that our lettuce plants thrive and avoid nutrient lockout issues.

Optimal Ph Range

Maintaining an ideal pH range between 5.5 and 6.5 is crucial for hydroponic lettuce as it directly affects nutrient availability and uptake.

When the pH deviates from this range, the solubility of essential minerals like nitrogen, phosphorus, and potassium decreases, impeding their absorption. This imbalance can lead to nutrient deficiencies, manifesting as limp or stunted growth.

By optimizing the pH, we guarantee the ion exchange capacity remains high, promoting efficient nutrient transport across cellular membranes.

In addition, a stable pH minimizes the risk of pathogenic growth, which can thrive in suboptimal conditions.

Achieving this delicate balance requires precise monitoring and adjustments, leveraging advanced pH control systems to maintain consistency, thereby fostering robust, healthy lettuce growth in our hydroponic systems.

Testing and Adjusting

To guarantee we stay within the ideal pH range, it's imperative that we regularly test and adjust the pH levels of our hydroponic solution using reliable pH meters and appropriate buffering agents.

Consistent monitoring guarantees our lettuce receives optimal nutrient uptake. We should aim for a pH range of 5.5 to 6.5. If the pH drifts outside this range, nutrient lockout can occur, leading to limp, undernourished plants.

By using a calibrated pH meter, we can obtain precise readings. If adjustments are necessary, we can employ pH up or pH down solutions. These buffering agents modify the solution's acidity or alkalinity, guaranteeing our hydroponic environment remains conducive to healthy lettuce growth.

Regularly recalibrating our meters is also essential for accuracy.

Light Conditions

Ideal light conditions play a critical role in guaranteeing robust growth and maximizing the yield of hydroponic lettuce.

We need to confirm that our lettuce receives a prime light spectrum, encompassing both blue and red wavelengths, which are essential for photosynthesis and vegetative growth. Utilizing LED grow lights allows us to tailor the light spectrum precisely.

The photoperiod, or the duration of light exposure, should ideally be between 14 to 16 hours per day, mimicking natural daylight cycles. Insufficient light can lead to etiolation, where plants become elongated and weak. Conversely, excessive light can cause photoinhibition, damaging the plant cells.

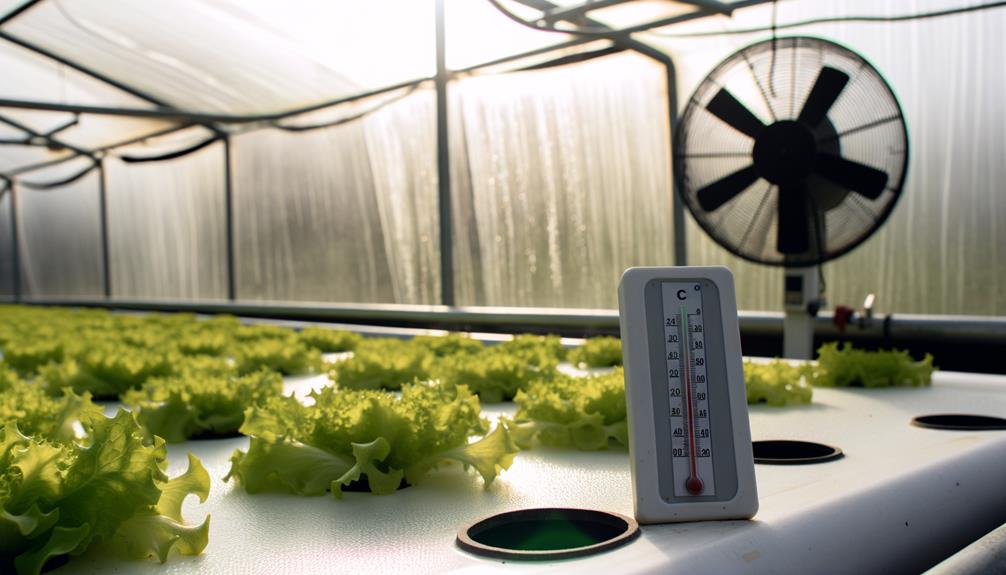

Temperature Fluctuations

Temperature fluctuations can wreak havoc on hydroponic lettuce growth, leading to issues like bolting and reduced nutrient uptake.

When temperatures vary widely, lettuce plants may enter a stress response, impacting their physiological processes. We need to maintain an ideal temperature range to guarantee consistent growth and nutrient absorption.

Here are three critical points to manage temperature effectively:

- Ideal Temperature Range: Keep water and air temperatures between 65-70°F (18-21°C) to prevent thermal stress.

- Temperature Monitoring Systems: Implement automated climate control systems to maintain stable conditions.

- Insulation and Ventilation: Utilize insulation to minimize external temperature influences and guarantee proper ventilation to dissipate excess heat.

Oxygen Levels

Maintaining ideal oxygen levels in the nutrient solution is just as essential as controlling temperature, as insufficient dissolved oxygen can lead to root hypoxia and hinder lettuce growth.

When oxygen levels drop, roots can't efficiently uptake nutrients and water, causing lettuce to become limp.

To optimize oxygenation, we should use air stones or diffusers to maintain dissolved oxygen concentrations above 5 ppm. Implementing a recirculating system guarantees constant aeration, while monitoring equipment like dissolved oxygen meters provides real-time feedback.

Additionally, maintaining a solution temperature between 18-22°C helps retain higher oxygen solubility.

Pest Infestations

Pest infestations present a significant challenge in hydroponic lettuce production, demanding vigilant monitoring and integrated pest management strategies to mitigate potential damage. We need to identify common pests like aphids, spider mites, and whiteflies that thrive in controlled environments. Employing an integrated approach guarantees we maintain crop health and productivity.

Key strategies include:

- Biological control: Introducing natural predators like ladybugs or parasitic wasps can keep pest populations in check without harmful chemicals.

- Cultural practices: Regularly inspecting plants and maintaining ideal environmental conditions can deter pests from establishing.

- Mechanical control: Using sticky traps and screens helps physically remove or block pests from accessing the crops.

Disease Management

Effectively managing diseases in hydroponic lettuce requires a thorough understanding of the pathogens that can infiltrate our systems and the conditions that facilitate their spread.

We must monitor our nutrient solutions, as imbalances can promote pathogens like Pythium and Fusarium. Ensuring ideal oxygenation levels in nutrient reservoirs minimizes anaerobic conditions, which pathogenic fungi prefer.

We should also implement UV sterilization or ozonation to reduce microbial load in water. Regularly inspecting roots for discoloration or slime helps us catch root rot early.

Sanitation practices, such as disinfecting tools and using pathogen-free planting materials, are critical.

Conclusion

In the end, our hydroponic garden is much like a finely tuned orchestra. Each element—nutrients, water quality, pH levels, light, temperature, oxygen, pest control, and disease management—plays its part.

When one component falters, the entire symphony suffers, resulting in limp lettuce.

Let's act as conductors, ensuring each section harmonizes perfectly, so our leafy greens can perform at their peak.

Remember, balance and vigilance are key to a thriving hydroponic system.