10 Key Differences: Air Pump vs Water Pump in Hydroponics

Air pumps and water pumps play vital roles in hydroponic systems with distinctive functionalities. Air pumps guarantee root oxygenation, essential for preventing hypoxic conditions and promoting vigorous root growth in systems like Deep Water Culture (DWC).

They operate at lower wattages and are rated by airflow capacity. Water pumps, on the other hand, are pivotal for nutrient solution circulation, guaranteeing uniform nutrient distribution and preventing deficiencies in setups such as Nutrient Film Technique (NFT).

These pumps are more energy-intensive but provide robust flow rates and efficient nutrient delivery. Understanding their functions and applications is essential for optimizing hydroponic system performance.

Key Takeaways

- Air pumps enhance root oxygenation, preventing hypoxia and promoting vigorous root growth in hydroponic systems.

- Water pumps ensure even nutrient distribution, crucial for larger hydroponic setups like NFT systems.

- Air pumps operate at lower wattages (5-15 Watts), making them energy-efficient for small to medium systems.

- Water pumps require more energy (20-100 Watts) but provide robust flow rates for extensive nutrient delivery.

Air Pumps Overview

Air pumps are frequently utilized in hydroponic systems to guarantee adequate oxygenation of the nutrient solution, thereby promoting ideal root health and plant growth.

The continuous aeration achieved through air pumps mitigates hypoxic conditions, which can lead to root rot and less-than-ideal nutrient uptake.

By delivering dissolved oxygen directly to the root zone, air pumps facilitate aerobic respiration essential for robust metabolism and growth.

Industry-standard air pumps are typically rated by their airflow capacity, measured in liters per minute (LPM), ensuring scalability for diverse system sizes.

Empirical evidence underscores that optimal dissolved oxygen levels, typically 5-8 ppm, can increase root biomass and enhance nutrient assimilation.

Consequently, air pumps serve as indispensable components in advanced hydroponic setups aimed at maximizing yield and plant health.

Water Pumps Overview

Integral to hydroponic systems, water pumps are essential for maintaining consistent nutrient solution circulation and delivery to plant roots. By guaranteeing that the nutrient solution remains evenly distributed, these pumps facilitate ideal plant growth and prevent nutrient deficiencies.

Key considerations when selecting a water pump include:

- Flow Rate: The volume of water the pump can move per hour, typically measured in gallons per hour (GPH).

- Head Height: The maximum height the pump can push water, vital for vertical or multi-tiered systems.

- Pump Type: Submersible pumps for smaller systems versus inline pumps for larger, more complex setups.

These factors collectively guarantee that the hydroponic environment remains efficient and productive.

Oxygenation Benefits

Oxygenation plays a pivotal role in hydroponic systems, directly influencing root health and nutrient uptake efficiency.

Enhanced oxygen levels promote vigorous root growth, reducing the risk of root rot and other anaerobic diseases.

Additionally, increased dissolved oxygen facilitates more efficient nutrient absorption, optimizing plant development and yield.

Root Health Enhancement

Ensuring ideal root health in hydroponic systems necessitates a thorough understanding of the oxygenation benefits provided by both air and water pumps. Oxygenation is critical for preventing root hypoxia and promoting robust growth.

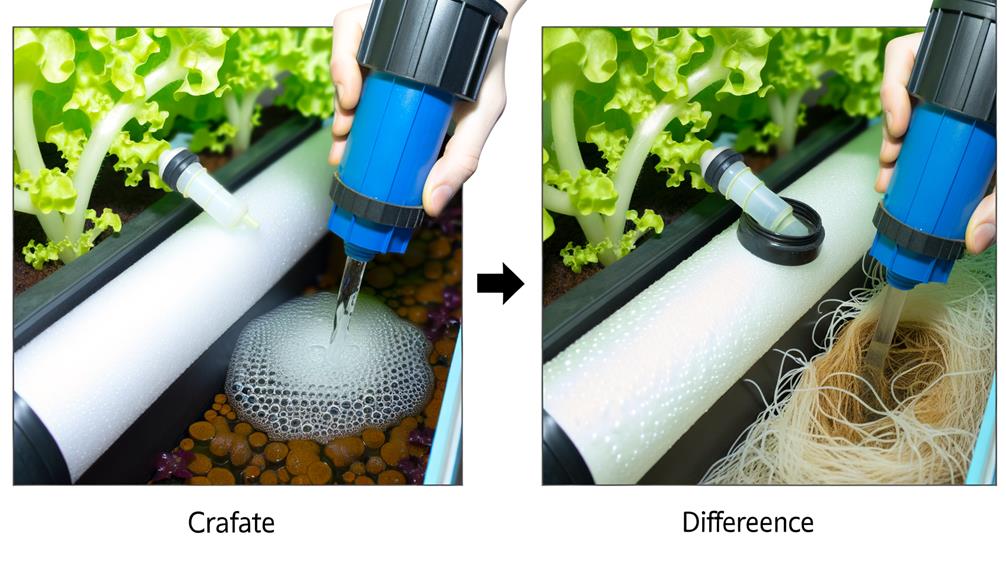

Air pumps deliver oxygen directly to the root zone through air stones, creating dissolved oxygen (DO) and enhancing root respiration. Conversely, water pumps circulate nutrient solutions, ensuring even DO distribution and preventing stagnation.

Key benefits of oxygenation include:

- Enhanced root respiration: Facilitates efficient energy production within root cells.

- Disease prevention: Reduces conditions favorable to anaerobic pathogens.

- Improved root morphology: Encourages development of a denser root system.

Understanding these mechanisms is essential for maximizing hydroponic system efficiency and root health.

Nutrient Uptake Efficiency

A well-oxygenated root environment greatly enhances nutrient uptake efficiency by facilitating ideal ion exchange and transport processes within the root cells.

Oxygenation, achieved through air or water pumps, considerably impacts the root zone's redox potential, promoting optimal root respiration and ATP production.

Evidence suggests that higher dissolved oxygen levels improve the solubility and mobility of essential nutrients like nitrogen, phosphorus, and potassium.

This enhanced nutrient availability directly correlates with increased biomass yield and plant vigor.

Additionally, oxygen-rich conditions mitigate hypoxic stress, thereby reducing the prevalence of root diseases.

Innovative hydroponic systems leveraging precise oxygenation techniques can consequently achieve superior nutrient assimilation, elevating overall plant performance and productivity.

Nutrient Delivery

In hydroponic systems, nutrient delivery mechanisms greatly impact plant health and growth rates.

The choice between air and water pumps influences nutrient distribution methods, with each offering varying levels of efficiency and consistency.

Additionally, the maintenance requirements for these systems differ, affecting long-term operational sustainability.

Nutrient Distribution Methods

Effective nutrient distribution methods are crucial in hydroponic systems to guarantee ideal plant growth and health. The mechanism of nutrient delivery can greatly impact root absorption efficiency and overall plant health. Both air and water pumps play critical roles in this process by facilitating the movement of nutrient-rich solutions.

- Drip Systems: Utilize emitters to deliver nutrients directly to the plant roots.

- Nutrient Film Technique (NFT): Circulates a thin film of nutrient solution over the roots.

- Deep Water Culture (DWC): Submerges roots in a continuously oxygenated nutrient solution.

These methods leverage advanced hydroponic technologies to optimize nutrient uptake, minimize waste, and enhance plant production.

Efficiency and Consistency

Ensuring efficiency and consistency in nutrient delivery is paramount for maintaining ideal plant growth and achieving high yields in hydroponic systems. Both air and water pumps play vital roles in nutrient delivery, yet they differ in performance metrics. Water pumps provide a direct, controlled nutrient flow, enhancing uptake efficiency and reducing stagnation. Conversely, air pumps aerate the nutrient solution, optimizing oxygenation but potentially causing inconsistent nutrient distribution. Empirical data underscores these distinctions:

| Feature | Water Pump | Air Pump |

|---|---|---|

| Nutrient Uptake Efficiency | High | Moderate |

| Oxygenation | Moderate | High |

| Consistency in Delivery | High | Variable |

| Energy Consumption | Variable (depending on flow rate) | Low |

Understanding these nuances enables hydroponic practitioners to tailor systems that maximize plant health and productivity through precise nutrient management. This careful customization helps growers optimize growth conditions, leading to higher yields and healthier plants. When comparing deep water culture vs hydroponics as a broader category, it’s essential to recognize that DWC is just one of many hydroponic methods, each with its own advantages and challenges. By selecting the right system and adjusting nutrient delivery accordingly, cultivators can achieve superior results tailored to their specific crops and environments.

System Maintenance Needs

Maintaining ideal nutrient delivery in hydroponic systems necessitates regular monitoring and maintenance of both air and water pumps to guarantee consistent performance and prevent system failures.

Ensuring the longevity and efficiency of these critical components involves several key steps:

- Routine Inspections: Regularly check for blockages and wear in pumps to preempt malfunctions.

- Cleaning Protocols: Implement stringent cleaning routines to prevent clogging and biofilm buildup.

- Component Replacement: Periodically replace worn-out parts like diaphragms, seals, and impellers to maintain optimal performance.

These practices are essential for maintaining the operational integrity of hydroponic systems, promoting robust plant growth, and achieving high yields.

Installation and Maintenance

Proper installation and regular maintenance are essential for optimizing the performance and longevity of both air pumps and water pumps in hydroponic systems.

For air pumps, ascertain correct placement above the water level to prevent backflow and verify all tubing connections are airtight to maximize oxygenation efficiency. Regularly inspect and clean air stones to prevent clogging, which can hinder root aeration.

Meanwhile, water pumps demand secure mounting to minimize vibrations and noise, alongside periodic cleaning of impellers and filters to maintain consistent water flow rates.

Both systems benefit from routine inspections for wear and tear, leaks, and electrical integrity.

Employing these best practices not only enhances system efficacy but also mitigates risks of operational failures, thereby fostering robust plant growth.

Cost Comparison

When evaluating the cost implications of air pumps versus water pumps in hydroponic systems, it is essential to take into account both initial investment and ongoing operational expenses.

Air pumps generally have a lower upfront cost compared to water pumps, but the latter might offer long-term savings through reduced maintenance needs.

Key factors influencing the cost comparison include:

- Initial Purchase Price: Air pumps are typically less expensive initially.

- Maintenance Requirements: Water pumps often require less frequent servicing.

- Replacement Cycle: Air pumps may need more frequent replacements due to wear.

Thus, a thorough cost analysis must consider these elements to determine the most economically viable option for a hydroponic setup.

Energy Efficiency

Evaluating the energy efficiency of air pumps versus water pumps in hydroponic systems requires a detailed analysis of their respective power consumption and operational performance. Air pumps, typically operating at lower wattages, offer energy savings and are suitable for small to medium-sized systems. Conversely, water pumps, while more energy-intensive, deliver robust flow rates essential for larger setups.

To illustrate:

| Parameter | Air Pumps | Water Pumps |

|---|---|---|

| Power Consumption | 5-15 Watts | 20-100 Watts |

| System Suitability | Small/Medium | Medium/Large |

| Operational Hours | Continuous | Intermittent |

| Energy Cost | Lower | Higher |

This nuanced understanding underscores the need for selecting the appropriate pump type based on specific hydroponic requirements and energy efficiency considerations.

Best Use Cases

Identifying the best use cases for air pumps and water pumps in hydroponics involves analyzing system size, plant type, and desired growth outcomes.

Air pumps are suitable for smaller systems like Deep Water Culture (DWC) where oxygenation is critical for root health.

Conversely, water pumps excel in larger setups like Nutrient Film Technique (NFT) and Ebb and Flow systems, providing efficient nutrient delivery.

- Air pumps are ideal for maintaining dissolved oxygen levels in small-scale DWC systems.

- Water pumps are essential for nutrient circulation in large-scale NFT systems.

- Air pumps support root health in systems where stagnant water poses a risk.

This strategic deployment guarantees enhanced plant growth and resource efficiency.

Conclusion

In the intricate dance of hydroponics, air pumps and water pumps serve as the crucial players, each with distinct roles akin to musicians in a symphony.

The air pump, like a flute, infuses life-sustaining oxygen, enhancing root respiration.

Conversely, the water pump, reminiscent of a cello, guarantees the seamless flow of nutrient solutions.

Proper orchestration of both elements, through meticulous installation and maintenance, culminates in a harmonious balance, optimizing plant growth and resource efficiency.