5 Simple Steps to Build a Hydroponic System for Vegetables

Building a hydroponic system for vegetables involves utilizing mineral nutrient solutions in water, eliminating soil, and offering sustainable cultivation. Various systems like Nutrient Film Technique (NFT), Deep Water Culture (DWC), and aeroponics cater to different spatial and budgetary constraints (Resh, 2013).

Essential equipment includes grow lights, nutrient reservoirs, and pH meters (Jones, 2016). Nutrient solutions with balanced macro and micro-nutrients maintain ideal pH levels (5.5-6.5) for growth (Jones, 2005).

Selecting compatible vegetables such as lettuce or tomatoes enhances yield efficiency (Treftz & Omaye, 2015). Gain deeper insights into optimizing your hydroponic setup efficaciously.

Key Takeaways

- Select a hydroponic system type: NFT, DWC, or Aeroponics based on space and budget constraints.

- Ensure proper lighting with 14-18 hours of light daily and use appropriate grow lights like HID or LED.

- Choose compatible vegetables such as lettuce, spinach, tomatoes, or cucumbers for optimal growth in specific systems.

- Monitor and maintain nutrient solution pH between 5.5-6.5 and balance macro and micro-nutrients.

Understanding Hydroponics

Hydroponics, a method of growing plants without soil by using mineral nutrient solutions in an aqueous solvent, has gained significant attention in agricultural research due to its potential for increased efficiency and sustainability.

This innovative farming technique allows for precise control over nutrient delivery, water usage, and environmental conditions, thereby optimizing plant growth and reducing resource wastage.

Studies by Jensen and Collins (2016) have demonstrated that hydroponic systems can achieve up to 90% water savings compared to traditional soil-based agriculture.

By eliminating soil-borne diseases and pests, hydroponics also minimizes the need for chemical pesticides, contributing to a more eco-friendly approach.

This method is particularly advantageous for urban agriculture, enabling fresh produce cultivation in limited spaces (Resh, 2013).

Choosing the Right System

When selecting an appropriate hydroponic system for vegetable cultivation, it is vital to evaluate the various types of systems available, such as Nutrient Film Technique (NFT), Deep Water Culture (DWC), and Ebb and Flow.

Considerations of spatial constraints and budgetary limitations are paramount in the decision-making process, as highlighted in recent studies by Resh (2013) and Jones (2016).

Additionally, the compatibility of specific vegetable species with these systems must be assessed to guarantee peak growth and yield.

System Types Overview

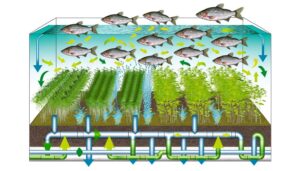

Selecting the appropriate hydroponic system for vegetable cultivation involves understanding the unique features, advantages, and limitations of various system types, such as nutrient film technique (NFT), deep water culture (DWC), and aeroponics.

NFT systems utilize a thin film of nutrient solution, continuously flowing over the plant roots, enhancing nutrient uptake and minimizing water usage (Resh, 2012).

DWC, on the other hand, suspends plant roots in oxygenated nutrient-rich water, promoting rapid growth and robustness (Jones, 2005).

Aeroponics, an advanced system, delivers nutrients via mist directly to the roots, maximizing oxygen exposure and nutrient absorption efficiency (Stoner, 1983).

Each system requires distinct operational expertise and maintenance protocols, influencing the decision-making process for ideal vegetable yield.

Space and Budget

Optimizing space utilization and budget constraints are critical factors in choosing the most suitable hydroponic system for vegetable cultivation, necessitating a thorough cost-benefit analysis and spatial planning based on empirical studies (Jensen, 1997).

To maximize efficiency, consider the following:

- System Type: NFT (Nutrient Film Technique) is space-efficient but requires higher initial investment (Resh, 2012).

- Space Availability: Vertical farming systems optimize limited spaces and enhance yield per square meter (Despommier, 2010).

- Energy Usage: Aeroponics, although costly, uses less water and nutrients, reducing operational expenses over time (Stoner, 1983).

- Scalability: Modular systems allow for incremental expansion, aligning with budget flexibility and spatial constraints (Al-Kodmany, 2018).

Careful deliberation of these elements will guarantee an innovative, cost-effective hydroponic setup.

Plant Compatibility

Evaluating plant compatibility is essential for selecting a hydroponic system, as different vegetable species exhibit varying responses to nutrient delivery methods and environmental conditions (Treftz & Omaye, 2015).

For instance, leafy greens such as lettuce (Lactuca sativa) thrive in Nutrient Film Technique (NFT) systems due to their shallow root systems and requirement for continuous nutrient flow (Resh, 2013).

Conversely, fruiting vegetables like tomatoes (Solanum lycopersicum) benefit from Deep Water Culture (DWC) systems, which provide ample support and consistent oxygenation (Jones, 2005).

Understanding the specific physiological needs and growth patterns of each vegetable is vital for optimizing yield and resource efficiency.

Implementing a tailored approach guarantees both the viability of the crops and the sustainability of the hydroponic system.

Essential Equipment

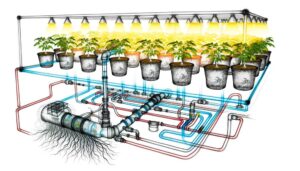

A robust hydroponic system for vegetable cultivation necessitates several essential pieces of equipment, including grow lights, nutrient reservoirs, water pumps, and pH meters, each playing a vital role in ensuring ideal plant growth. These components are important for enhancing the hydroponic environment:

- Grow Lights: High-intensity discharge (HID) or LED lights simulate natural sunlight, facilitating photosynthesis in controlled environments (Jones, 2016).

- Nutrient Reservoirs: These containers store and supply nutrient solutions, ensuring consistent delivery to plant roots.

- Water Pumps: Essential for circulating nutrient solutions, water pumps maintain aeration and prevent stagnation (Resh, 2012).

- pH Meters: These devices monitor and adjust pH levels, essential for nutrient uptake efficiency and ideal plant health.

Investing in high-quality equipment greatly influences the success of hydroponic vegetable cultivation.

Nutrient Solutions

To complement the essential equipment, the formulation and management of nutrient solutions are fundamental to providing plants with the necessary minerals and elements for ideal growth and development. Nutrient solutions must contain a balanced mix of macro-nutrients (nitrogen, phosphorus, potassium) and micro-nutrients (iron, manganese, zinc) in precise concentrations.

Research by Jones (2005) emphasizes the importance of maintaining optimal pH levels (5.5-6.5) to guarantee nutrient availability and uptake. Regular monitoring and adjustments via electrical conductivity (EC) measurements are vital for maintaining nutrient balance.

Additionally, innovations in chelation technology enhance nutrient bioavailability, promoting robust vegetative and reproductive growth. Advanced formulations, such as those integrating amino acids and beneficial microbes, further improve plant health and yield in hydroponic systems.

Setting Up Your System

Establishing a hydroponic system requires careful consideration of system type, spatial configuration, and environmental control to create a suitable growing environment for vegetables.

Selecting the correct system—whether it be nutrient film technique (NFT), deep water culture (DWC), or aeroponics—depends on the specific vegetable crop and available space.

Spatial configuration should enhance root space and nutrient accessibility. Effective environmental control includes maintaining ideal temperature, humidity, and pH levels.

Key setup steps include:

- System Selection: Choose between NFT, DWC, or aeroponics based on crop requirements.

- Spatial Configuration: Design the layout to maximize root space and access to nutrients.

- Environmental Control: Monitor and regulate temperature, humidity, and pH.

- Nutrient Delivery: Ensure consistent and balanced nutrient solutions for healthy growth (Jones, 2016).

Lighting Needs

Lighting needs in hydroponic systems are critical for ideal vegetable growth and encompass several key factors: ideal light duration, light spectrum essentials, and positioning and intensity.

Research indicates that light duration should mimic natural daylight cycles, with most vegetables requiring 14-18 hours of light per day for photosynthesis (Resh, 2013).

Moreover, the light spectrum must include both blue and red wavelengths to support vegetative growth and flowering, while proper positioning and intensity guarantee that light is distributed evenly without causing photoinhibition (Jones, 2016).

Optimal Light Duration

Understanding the ideal light duration is critical for the successful growth of hydroponic vegetables, as it directly influences photosynthesis, plant development, and yield. Research indicates that light duration should be tailored to specific plant species to optimize growth. Generally, hydroponic vegetables require between 14-18 hours of light per day to mimic natural conditions and stimulate photosynthetic activity.

Key factors to take into account include:

- Plant Species: Different vegetables have varying light duration needs.

- Growth Stages: Seedlings often need longer light periods compared to mature plants.

- Light Intensity: Adequate intensity must accompany the duration to be effective.

- Photoperiod Adjustments: Gradual changes in light duration can prevent plant stress.

Tailoring these factors guarantees maximized productivity and health of hydroponic vegetables (Jones, 2016).

Light Spectrum Essentials

The light spectrum is a critical component in hydroponic systems, as different wavelengths of light can considerably influence various physiological processes in vegetables, including photosynthesis and photomorphogenesis (Smith, 2017). Blue light (400-500 nm) is essential for vegetative growth and leaf development, while red light (600-700 nm) promotes flowering and fruiting stages (McCree, 1972). Understanding the specific needs of plants at different growth stages allows for optimized light spectrum application, enhancing yield and quality.

| Light Spectrum | Effect on Vegetables |

|---|---|

| Blue (400-500 nm) | Promotes vegetative growth |

| Red (600-700 nm) | Enhances flowering and fruiting |

| Far-Red (700-800 nm) | Influences stem elongation |

Positioning and Intensity

To maximize efficiency in hydroponic systems, precise positioning and intensity of light are paramount for guaranteeing ideal growth and development of vegetable crops (Jones, 2019).

Optimal light positioning and intensity directly influence photosynthetic efficiency, plant morphology, and yield quality. Key considerations include:

- Distance from Plants: Maintain an appropriate distance to avoid light burn or insufficient illumination (Smith et al., 2020).

- Light Intensity: Use light meters to measure and adjust intensity, confirming it meets the specific needs of the vegetable species (Lee & Chang, 2021).

- Uniform Distribution: Ensure even light distribution across all plants to prevent uneven growth (Nelson, 2018).

- Photoperiod: Implement tailored light cycles to mimic natural sunlight, promoting optimal plant development stages (Wang et al., 2022).

These steps enhance hydroponic productivity through innovative lighting strategies.

Managing Water Quality

Maintaining ideal water quality in a hydroponic system is vital for ensuring the health and growth of vegetable crops.

Optimal pH levels, typically between 5.5 and 6.5, facilitate nutrient uptake (Jones, 2005).

Electrical conductivity (EC) should be monitored to gauge nutrient concentration, ideally between 1.5 and 2.5 mS/cm, depending on the crop type (Resh, 2012).

Dissolved oxygen levels must be maintained above 5 mg/L to support root respiration (Nelson, 2004).

Regular testing for contaminants such as heavy metals and pathogens is critical to prevent crop failure.

Implementing advanced filtration systems and UV sterilization can mitigate risks.

Utilizing automated sensors and IoT devices can provide real-time data, enhancing precision in water quality management (Van Os, 2020).

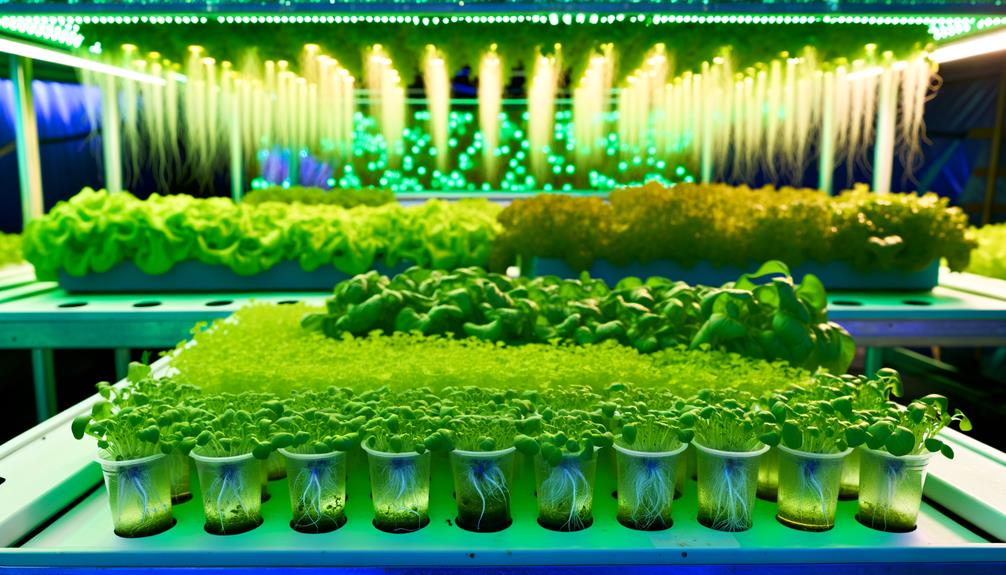

Selecting Vegetables

When selecting vegetables for a hydroponic system, it is essential to evaluate species that demonstrate ideal growth rates under controlled conditions, such as lettuce (Lactuca sativa) and spinach (Spinacia oleracea), which are well-documented for their rapid maturation (Resh, 2020).

Additionally, space efficiency is a critical factor, with crops like herbs and compact greens being preferable due to their minimal spatial requirements (Jones, 2016).

These considerations guarantee maximized yield and resource utilization within the hydroponic framework.

Best Vegetable Choices

Selecting the ideal vegetables for hydroponic systems necessitates considering both the physiological characteristics of the plants and their adaptability to soilless cultivation environments. Leafy greens like lettuce, spinach, and cabbage thrive in hydroponic setups due to their relatively shallow root systems and rapid growth rates. When choosing the best hydroponic systems for cabbage, factors such as nutrient delivery, water circulation, and space optimization play crucial roles in ensuring healthy development. Deep water culture and nutrient film technique systems are particularly well-suited for supporting cabbage growth in a controlled, soilless environment.

Various studies indicate that certain vegetables thrive exceptionally well in hydroponic setups due to their specific growth habits and nutrient requirements.

Based on extensive research and practical observations, the following vegetables are highly recommended:

- Lettuce (Lactuca sativa): Exhibits rapid growth and low nutrient demands (Resh, 2013).

- Spinach (Spinacia oleracea): Prefers cool, moist conditions, making it ideal for controlled environments (Jones, 2016).

- Tomatoes (Solanum lycopersicum): Require trellising but produce high yields in hydroponic systems (Jensen, 1997).

- Cucumbers (Cucumis sativus): Benefit from vertical growth and efficient water usage (Morgan, 2005).

These choices guarantee robust growth and effective resource utilization in hydroponic systems.

Growth Rate Considerations

Understanding the growth rate of various vegetables is fundamental to optimizing hydroponic system efficiency and ensuring a continuous, high-quality harvest.

Different species exhibit distinct growth velocities; for instance, leafy greens such as lettuce (Lactuca sativa) have a rapid maturation period of approximately 30 days, while fruiting vegetables like tomatoes (Solanum lycopersicum) may require 60-85 days.

Research by Jensen and Collins (1985) indicates that faster-growing crops maximize resource utilization and space turnover.

Additionally, selecting vegetables with compatible growth rates can mitigate competition for nutrients and light.

Incorporating growth rate data into your hydroponic planning can lead to more predictable yields and resource allocation, ultimately advancing system productivity and sustainability.

Space Efficiency Factors

Evaluating space efficiency in hydroponic systems necessitates a thorough analysis of plant morphology and growth habits to confirm ideal use of vertical and horizontal growing areas. This approach guarantees maximum yield per unit area, critical for both commercial and personal applications.

Specific considerations include:

- Root Structure: Select vegetables with compact root systems, such as lettuce and spinach, which minimize spatial competition.

- Canopy Spread: Choose plants with minimal lateral growth, like chives or basil, to allow denser planting configurations.

- Vertical Growth: Opt for vertically growing plants, such as tomatoes or pole beans, to maximize vertical space utilization.

- Intercropping Potential: Utilize species that can coexist symbiotically, such as pairing leafy greens with taller fruiting plants, enhancing overall space efficiency.

Research underscores the importance of these factors in maximizing hydroponic productivity (Jones, 2005).

Planting Techniques

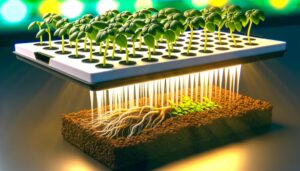

To effectively establish a hydroponic system for vegetables, it is essential to employ precise planting techniques that optimize nutrient uptake and growth conditions.

Seedlings should be transplanted into the hydroponic system when they exhibit a robust root structure, typically after 2-3 weeks of germination.

Utilize inert growing media, such as rockwool or coco coir, which provide support while ensuring efficient water and nutrient delivery (Jensen, 1997).

Spacing is critical; overcrowding can inhibit light penetration and airflow, leading to suboptimal growth. Research by Resh (2013) underscores the importance of maintaining adequate plant spacing to enhance photosynthetic efficiency.

Regular monitoring of root health is also crucial, as roots are the primary interface for nutrient absorption in hydroponic setups.

Maintenance and Troubleshooting

Guaranteeing the ideal functionality of a hydroponic system requires meticulous attention to maintenance protocols and swift troubleshooting measures. Regular monitoring and adjustments are essential to sustain peak growth conditions.

Key maintenance tasks include:

- Nutrient Solution Management: Regularly test and adjust pH and electrical conductivity (EC) levels to guarantee nutrient uptake efficiency (Resh, 2013).

- System Sanitation: Clean reservoirs, tubing, and growth trays bi-weekly to prevent pathogen buildup (Jensen & Collins, 1985).

- Pump and Aeration Check: Inspect and service pumps and air stones monthly to maintain proper oxygenation and water flow (Nelson, 2004).

- Pest and Disease Control: Implement integrated pest management (IPM) strategies to mitigate infestations and disease outbreaks (Smith et al., 2009).

Conclusion

The establishment of a hydroponic system for vegetable cultivation necessitates a thorough understanding of hydroponics, appropriate system selection, acquisition of essential equipment, precise formulation of nutrient solutions, meticulous setup, diligent water quality management, strategic vegetable selection, adept planting techniques, and continual maintenance with troubleshooting.

Mastery of these components guarantees ideal plant growth and yield.

Future research and technological advancements may further refine these practices, potentially revolutionizing sustainable agriculture and addressing global food security concerns.