How You Can Grow Hops Hydroponically: A Step-by-Step Guide

Yes, hops can be effectively cultivated using hydroponic systems. Hydroponics, involving growth in nutrient-rich solutions without soil, permits precision control over environmental variables such as pH, temperature, and light intensity.

This method mitigates soil-borne diseases, optimizes water usage, and enhances yield quality. Common systems like Deep Water Culture (DWC) and Nutrient Film Technique (NFT) provide continuous nutrient delivery and oxygenation.

Proper management of macro and micronutrients, full-spectrum LED lighting, and controlled temperature and humidity are vital. Advanced sensors and automation streamline these processes, ensuring superior growth conditions.

Learn more about essential equipment, nutrient management, pest control, and harvesting techniques.

Key Takeaways

- Hydroponics allows hops to be grown without soil, using nutrient-rich aqueous solutions.

- Enhanced control over environmental factors increases hops' yield and quality.

- Hydroponic systems reduce the risk of soil-borne diseases and pests.

- Efficient water usage in hydroponics minimizes environmental impact.

What Is Hydroponics?

Hydroponics, a method frequently employed in modern agriculture, involves the cultivation of plants in a nutrient-rich, aqueous solution without the use of soil. This system leverages water as the primary medium for delivering essential minerals and nutrients directly to plant roots.

Advanced hydroponic techniques utilize various substrates such as perlite, vermiculite, or rock wool to provide structural support while maintaining ideal aeration and moisture levels.

Precision control over environmental variables such as pH, temperature, and light intensity is paramount in hydroponic systems, ensuring maximal growth efficiency and yield.

This soil-less cultivation method is especially advantageous in controlled environments like greenhouses or indoor farms, where resource optimization and sustainability are prioritized to meet the demands of innovative agricultural practices.

Benefits of Hydroponic Hops

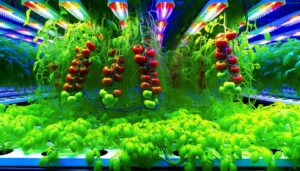

One of the primary advantages of cultivating hops hydroponically is the enhanced control over growth conditions, which leads to increased yield and quality.

By utilizing hydroponic systems, growers can fine-tune nutrient delivery, pH levels, and environmental parameters such as light and humidity. This precision allows for the optimization of photosynthesis and metabolic processes, resulting in more robust plant development. Additionally, this controlled approach minimizes the risk of soil-borne diseases and reduces water consumption compared to traditional soil-based methods. For example, those who grow dill hydroponically can ensure consistent access to essential nutrients, leading to faster growth and higher yields. Furthermore, hydroponic systems allow for year-round cultivation, making it easier to produce fresh herbs regardless of seasonal changes.

Additionally, hydroponic cultivation mitigates soil-borne diseases and pest infestations, contributing to healthier plants. The closed-loop systems employed in hydroponics also enable efficient water usage, reducing the overall environmental footprint.

Consequently, hydroponically grown hops exhibit superior consistency and potency, making them highly desirable for brewers seeking high-quality ingredients with predictable characteristics.

Choosing the Right System

Selecting an appropriate hydroponic system for cultivating hops necessitates a thorough understanding of various system types, such as Nutrient Film Technique (NFT), Deep Water Culture (DWC), and Ebb and Flow.

Each system presents unique advantages and challenges, influencing factors like nutrient delivery, root support, and oxygenation.

Additionally, key system components such as pumps, reservoirs, and grow lights must be meticulously chosen to optimize plant health and yield.

System Types Overview

Understanding the various hydroponic system types is essential for enhancing hop growth and ensuring successful cultivation.

Among the primary systems, Deep Water Culture (DWC) offers continuous nutrient availability through submersion, ideal for robust root development.

Nutrient Film Technique (NFT) provides a thin film of nutrients, promoting efficient uptake and oxygenation, which can enhance the growth rate.

Aeroponics, utilizing misted nutrient solutions, maximizes root oxygenation, potentially accelerating biomass production.

Ebb and Flow systems, characterized by periodic flooding and draining, maintain ideal nutrient and oxygen levels.

Each system has distinct advantages and operational complexities, necessitating a thorough analysis of resource availability, scalability, and maintenance requirements to align with the specific needs of hop cultivation.

Key System Components

To maximize hop cultivation hydroponically, it is essential to meticulously evaluate and select key system components such as pumps, reservoirs, grow lights, and nutrient delivery mechanisms based on their compatibility and efficiency.

Advanced submersible pumps guarantee consistent nutrient flow, while high-capacity reservoirs facilitate balanced nutrient distribution. Full-spectrum LED grow lights, simulating natural sunlight, promote vigorous photosynthesis. Precision nutrient delivery systems, incorporating automated dosing and pH adjustment, maintain ideal nutrient profiles.

Additionally, selecting an appropriate growth medium, such as coco coir or perlite, guarantees adequate root aeration and moisture retention. Integrating environmental control units to regulate temperature, humidity, and CO2 levels further enhances hop plant development.

Thorough system integration ensures robust and efficient hop production.

Essential Equipment Needed

A successful hydroponic hops cultivation system requires a range of specialized equipment designed to optimize plant growth and yield.

Essential components include a high-quality grow tent or greenhouse equipped with reflective interior surfaces to maximize light efficiency.

Advanced LED grow lights with adjustable spectrums are critical for providing the correct light wavelengths throughout the growth phases.

A reliable hydroponic system, such as Deep Water Culture (DWC) or Nutrient Film Technique (NFT), is indispensable for nutrient delivery.

Additionally, precise environmental controls, including HVAC systems for temperature and humidity regulation, CO2 injectors for enhanced photosynthesis, and pH and EC meters for real-time nutrient solution monitoring, are crucial.

Nutrient Solutions for Hops

Nutrient solutions are critical for the ideal growth of hydroponic hops, necessitating a precise balance of essential macro and micronutrients.

Maintaining an ideal pH level, typically between 5.8 and 6.5, guarantees nutrient availability and uptake efficiency.

Additionally, the frequency of nutrient solution replacement must be carefully managed to prevent nutrient imbalances and guarantee sustained plant health.

Essential Nutrient Components

Optimizing nutrient solutions for hydroponically grown hops necessitates a thorough understanding of essential macro and micronutrients, along with their specific concentration ranges and interactions. Key macro-nutrients such as Nitrogen (N), Phosphorus (P), and Potassium (K) play vital roles in vegetative growth, root development, and flowering. Equally important are micro-nutrients like Iron (Fe), Manganese (Mn), and Zinc (Zn), which facilitate enzymatic functions and physiological processes. Balancing these nutrients is essential for maximizing hop yield and quality. Below is a table detailing the ideal concentration ranges for these nutrients in hydroponic systems:

| Nutrient | Macro/Micro | Ideal Concentration (ppm) |

|---|---|---|

| Nitrogen (N) | Macro | 150-200 |

| Phosphorus (P) | Macro | 30-50 |

| Potassium (K) | Macro | 200-250 |

| Iron (Fe) | Micro | 2-3 |

| Manganese (Mn) | Micro | 0.5-1.0 |

Optimal Ph Levels

Maintaining an ideal pH range of 5.8 to 6.2 in nutrient solutions is vital for the efficient absorption of macro and micronutrients in hydroponically grown hops. This pH range maximizes the availability of nitrogen, phosphorus, potassium, and trace elements, essential for robust vegetative growth and cone development.

Deviations from this range can precipitate nutrient lockout, leading to deficiencies or toxicities that impair plant health. Continuous pH monitoring and adjustments using pH buffers or acid/base solutions guarantee stability.

Employing high-precision pH meters and automated dosing systems can enhance control, reducing the risk of human error. An ideal pH environment fosters vigorous root systems and guarantees that hops achieve their full genetic potential in a hydroponic setup.

Nutrient Solution Frequency

Determining the appropriate frequency for applying nutrient solutions is a critical factor in the successful hydroponic cultivation of hops, guaranteeing plants receive consistent and adequate nourishment for ideal growth and cone production. A suitable schedule must be maintained to balance nutrient absorption and root health.

Typically, nutrient solution application frequency can vary based on several parameters:

- Plant Development Stage: Young plants require less frequent but consistent nutrient supply, whereas mature plants need more frequent applications to support vigorous growth.

- System Type: Systems like Deep Water Culture (DWC) may require less frequent changes compared to Nutrient Film Technique (NFT) due to different root exposure levels.

These considerations guarantee hops receive suitable nourishment for robust development.

Light Requirements

Proper light requirements are essential for the successful hydroponic cultivation of hops, necessitating the use of full-spectrum grow lights to mimic the natural photoperiod and intensity of sunlight.

Hops (Humulus lupulus) require a photoperiod of approximately 16-18 hours of light during the vegetative stage to guarantee ideal growth and development.

Employing high-intensity discharge (HID) lights or light-emitting diodes (LEDs) with a spectrum of 400-700 nanometers will facilitate photosynthesis and promote robust plant morphology.

Importantly, maintaining a consistent light schedule is critical to prevent photoperiod stress, which can adversely affect flowering and cone production.

Advanced lighting systems equipped with programmable timers and adjustable spectra can greatly enhance the efficiency and yield of hydroponically grown hops.

Temperature and Humidity Control

Effective temperature and humidity control is vital in hydroponic hop cultivation to secure ideal plant health and maximize yield potential.

Prime conditions for hop growth necessitate precise regulation of environmental variables. Temperature should remain within the 18-25°C range to facilitate photosynthesis and enzymatic activities essential for growth. Meanwhile, maintaining humidity levels between 40-60% prevents mold proliferation and guarantees adequate transpiration.

Key strategies include:

- Climate Control Systems: Utilize automated HVAC systems to stabilize temperature and humidity.

- Sensor Technology: Implement advanced sensors for real-time monitoring and adjustments.

These methodologies enhance growth efficiency, leading to robust hop development and superior crop quality.

Managing Pests and Diseases

While maintaining ideal temperature and humidity is paramount, it is equally imperative to implement rigorous pest and disease management protocols to preserve the health and productivity of hydroponically grown hops.

Integrated Pest Management (IPM) strategies are essential, combining biological control agents such as predatory mites and beneficial nematodes with periodic monitoring and mechanical controls.

Employing systemic insecticides and fungicides, compatible with hydroponic systems, can also mitigate infestations and pathogenic outbreaks.

Additionally, maintaining optimal nutrient levels and pH balance deters pathogen proliferation.

Employing UV sterilization and guaranteeing proper air circulation can further reduce microbial threats.

Advanced diagnostic tools, like PCR assays, enable early detection of viral pathogens, facilitating prompt remediation.

This multi-faceted approach guarantees robust plant health and sustained yield.

Harvesting Hydroponic Hops

Achieving ideal yields from hydroponically grown hops necessitates precise timing and methodical techniques during the harvesting process. The best harvest window is critical, typically when 80% of hop cones exhibit a dry, papery texture and emit a robust aroma. Advanced hydroponic systems allow for controlled environmental conditions, guaranteeing consistency in hop maturation.

Key considerations include:

- Cone Maturity Assessment: Employing refractometers to measure lupulin gland development and moisture content.

- Harvest Automation: Utilizing automated trimmers and conveyors to enhance efficiency and reduce labor costs.

These strategies collectively guarantee that hydroponically grown hops meet the quality standards required for premium brewing applications.

Challenges to Consider

Despite the benefits of controlled environments in hydroponic systems, several challenges can impede the optimization of hop production.

Key issues include maintaining consistent nutrient concentrations and pH levels, which are critical for hop growth. Temperature regulation is another hurdle; hops require a specific temperature range to thrive, and deviations can impact yield and quality.

Additionally, the vertical growth habit of hops necessitates robust structural support systems within the hydroponic setup. Pest and disease management also poses a significant challenge, as the closed environment can exacerbate infestations.

Moreover, the high initial capital investment for hydroponic infrastructure and the ongoing operational costs may deter some growers. Addressing these obstacles requires precise monitoring, advanced technology, and significant expertise.

Conclusion

Hydroponic cultivation of hops presents a viable and innovative method for optimizing growth conditions and yield.

One compelling statistic reveals that hydroponic systems can use up to 90% less water than traditional soil-based agriculture. This efficiency, combined with precise control over nutrient delivery and environmental factors, underscores the potential for hydroponics to revolutionize hop production.

While challenges such as initial setup costs and pest management persist, the advantages of hydroponic cultivation offer a promising future for sustainable agriculture.