5 Simple Steps for You to Grow Squash Hydroponically

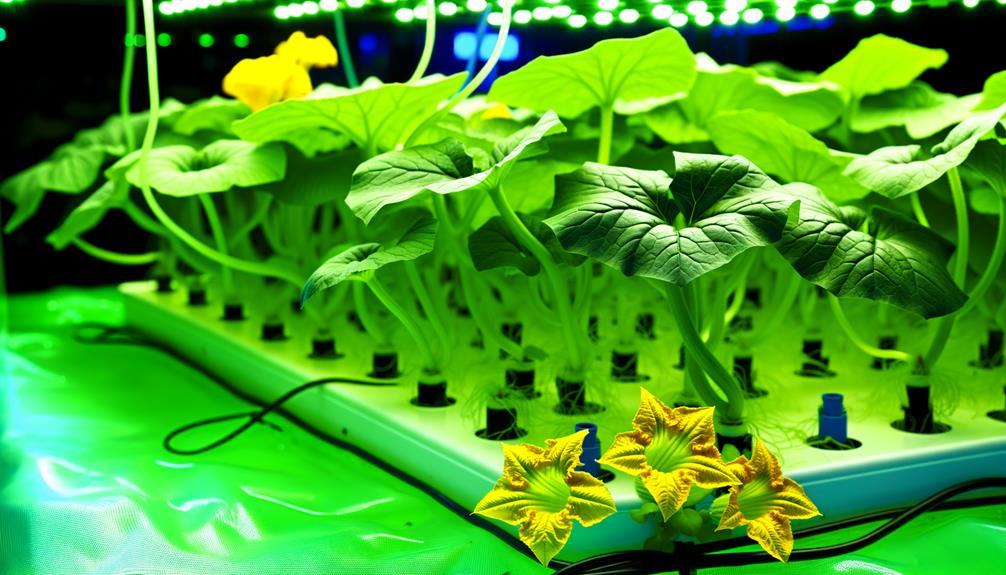

Yes, squash can be grown hydroponically with excellent results. Hydroponic systems such as nutrient film technique (NFT) or deep water culture (DWC) provide precise nutrient and water management, promoting rapid growth and high yields.

By avoiding soil, the risk of soil-borne diseases and pests is greatly reduced, ensuring healthier plants. Optimum nutrient formulations and controlled pH levels are essential for hydroponic success, as are full-spectrum LED lighting to mimic sunlight.

Proper support structures and manual pollination techniques are often necessary for robust growth and fruit set. Explore advanced methods to further enhance your hydroponic squash production.

Key Takeaways

- Yes, squash can be grown hydroponically with optimized nutrient delivery and controlled environments.

- Hydroponic systems like NFT and DWC ensure efficient water and nutrient usage for growing squash.

- Compact squash varieties, such as 'Black Beauty' zucchini, are ideal for hydroponic setups.

- Full-spectrum LED lighting and precise climate control enhance squash growth in hydroponic systems.

Benefits of Hydroponic Squash

Cultivating squash hydroponically offers numerous advantages, including enhanced growth rates, optimized nutrient delivery, and efficient water usage.

Hydroponic systems facilitate precise control over nutrient concentrations, ensuring that squash plants receive an ideal balance of essential elements like nitrogen, phosphorus, and potassium. This optimization accelerates metabolic processes, leading to faster growth and higher yields.

Additionally, hydroponic setups considerably reduce water consumption compared to traditional soil-based methods, as the closed-loop systems recycle water, minimizing waste.

The absence of soil also mitigates the risks associated with soil-borne diseases and pests, contributing to healthier plant development.

Advanced technologies such as automated nutrient dosing and pH monitoring further refine the growing environment, making hydroponic cultivation a sophisticated and sustainable approach for producing premium-quality squash. These innovations ensure precise control over essential growth factors, leading to higher yields and reduced resource waste. Farmers who grow hydroponic butter lettuce can apply similar techniques to optimize conditions for various crops, including squash. As a result, hydroponic farming becomes a reliable method for consistently achieving healthy, robust produce.

Choosing Squash Varieties

Selecting the appropriate squash varieties for hydroponic cultivation involves evaluating factors such as growth habit, space requirements, and susceptibility to diseases, ensuring compatibility with the specific hydroponic system used. Varieties like 'Black Beauty' zucchini and 'Early Prolific Straightneck' yellow squash are exemplary choices due to their compact growth habits and robust disease resistance. Conversely, vining varieties may necessitate more sophisticated support structures and spatial management within the hydroponic setup. Analyzing the specific characteristics of each variety can optimize yield and resource efficiency.

| Squash Variety | Key Characteristics |

|---|---|

| Black Beauty Zucchini | Compact growth, disease-resistant |

| Early Prolific Straightneck | Space-efficient, high-yielding |

| Tromboncino | Vining habit, requires trellising |

Selecting the right variety enhances overall system performance and crop output.

Hydroponic Systems for Squash

Selecting an appropriate hydroponic system for squash cultivation necessitates understanding efficient nutrient delivery methods, such as nutrient film technique (NFT) and deep water culture (DWC), to guarantee peak growth and yield.

Regular system maintenance, including monitoring pH levels and preventing pathogen buildup, is critical to sustaining plant health.

Employing these strategies will maximize resource utilization and enhance overall productivity in hydroponic squash production.

Nutrient Delivery Methods

Employing various hydroponic systems such as nutrient film technique (NFT), deep water culture (DWC), and drip irrigation is vital for optimizing nutrient delivery to squash plants.

NFT guarantees a continuous flow of nutrient-rich solution over the root zone, promoting efficient uptake and oxygen availability.

DWC, on the other hand, submerges roots directly in nutrient solutions, enabling constant access to nutrients and dissolved oxygen.

Drip irrigation precisely delivers nutrients to the root zone, reducing waste and guaranteeing uniform distribution.

Each method offers distinct advantages, facilitating tailored nutrient management strategies.

Advanced monitoring tools and automation can further enhance nutrient delivery, fostering robust growth and higher yields in hydroponically grown squash.

System Maintenance Tips

Ensuring the ideal performance of hydroponic systems for squash necessitates meticulous system maintenance practices that include regular monitoring of pH levels, nutrient concentrations, and water quality.

Consistent pH levels between 5.5 and 6.5 are essential for optimal nutrient uptake. Employing precise pH meters and calibration solutions is recommended.

Nutrient solution reservoirs should be checked and replenished weekly to maintain balanced macro and micronutrient profiles.

Water quality must be maintained by filtering impurities and routinely checking for electrical conductivity (EC) values, preferably between 1.2 to 2.0 mS/cm.

Additionally, system components such as pumps and tubing must be inspected bi-weekly for blockages or wear, ensuring continuous and efficient nutrient delivery.

Regular maintenance mitigates the risk of pathogen proliferation and maximizes squash yield.

Nutrient Solutions

Proper formulation and management of nutrient solutions are critical for maximizing the growth and yield of hydroponically grown squash. Essential macro and micronutrients must be meticulously balanced to support various growth stages. Nutrient solutions should contain:

| Nutrient | Concentration (ppm) |

|---|---|

| Nitrogen (N) | 150-200 |

| Phosphorus (P) | 50-60 |

| Potassium (K) | 200-250 |

Maintaining an electrical conductivity (EC) between 1.8 and 2.4 mS/cm and a pH range of 5.5 to 6.5 guarantees ideal nutrient uptake. Regular monitoring is imperative to adjust concentrations based on plant development. Advanced nutrient formulations can incorporate chelated elements to enhance bioavailability, thereby promoting vigorous growth and high yields. Employing automated dosing systems can further streamline nutrient management, guaranteeing precision and consistency.

Lighting Requirements

Lighting requirements for hydroponic squash cultivation necessitate precise control over light intensity, duration, and type.

Ideal light intensity guarantees maximal photosynthetic efficiency, while appropriate light duration aligns with the circadian rhythms of the plant.

Utilizing the best light types, such as full-spectrum LEDs, can greatly enhance growth and yield by closely mimicking natural sunlight conditions.

Optimal Light Intensity

Ideal light intensity for growing squash hydroponically is essential to maximizing photosynthesis and guaranteeing robust plant growth.

Squash plants require a Photosynthetically Active Radiation (PAR) range of 400-700 μmol/m²/s to maximize chlorophyll absorption.

Utilizing full-spectrum LED grow lights, which can deliver consistent light quality, is recommended.

Additionally, maintaining a light intensity of approximately 600-1000 μmol/m²/s at canopy level can greatly enhance vegetative and reproductive phases.

Employing precision light meters guarantees accurate monitoring and adjustments, vital for preventing photoinhibition or insufficient light exposure.

Leveraging advanced light management techniques, such as supplemental side lighting and dynamic light intensity modulation, can further improve yields and plant health.

Proper light intensity is indispensable for achieving ideal growth outcomes in hydroponically cultivated squash.

Light Duration Needs

Determining the ideal light duration for hydroponically grown squash is critical to guaranteeing the plants undergo adequate photoperiods for both vegetative growth and flowering stages. Light duration directly influences photomorphogenesis and photosynthesis, key processes for peak plant development. Typically, a light cycle of 16-18 hours per day during the vegetative phase is recommended, while a 12-14 hour light cycle is best during the flowering phase. Precise control of light duration can enhance yield and quality. Below is a table summarizing light duration needs for various growth stages:

| Growth Stage | Light Duration (hours/day) | Photoperiod Impact |

|---|---|---|

| Seedling | 16-18 | Promotes germination |

| Vegetative | 16-18 | Enhances leaf growth |

| Flowering | 12-14 | Stimulates flowering |

| Fruiting | 12-14 | Supports fruit set |

Proper management of these parameters guarantees robust growth and maximizes hydroponic efficiency.

Best Light Types

To enhance hydroponic squash growth, selecting the most efficient light types is essential for guaranteeing adequate photosynthetic photon flux density (PPFD) and spectral quality tailored to different growth phases.

Light-emitting diodes (LEDs) are highly recommended due to their energy efficiency, customizable spectra, and longevity. Full-spectrum LEDs, particularly those with a high red-to-blue light ratio, are ideal for vegetative growth and flowering stages.

High-Pressure Sodium (HPS) lights, though energy-intensive, offer high-intensity light suitable for fruiting. Metal Halide (MH) lights provide a blue-rich spectrum beneficial during early vegetative stages.

Integrating these light systems through a dynamic photoperiod strategy guarantees ideal growth rates and yield, fostering innovation in hydroponic squash cultivation.

Temperature and Humidity

Maintaining ideal temperature and humidity levels is essential for maximizing the growth and yield of hydroponically grown squash.

Optimal temperature ranges between 70-85°F (21-29°C) during the day and slightly cooler at night to stimulate robust photosynthetic activity and metabolic processes.

Humidity levels should be maintained between 50-70%, as excessive humidity can lead to fungal diseases, while low humidity can cause transpiration stress.

Utilizing automated climate control systems, such as HVAC units and humidifiers/dehumidifiers, guarantees precise regulation of these parameters.

Additionally, employing advanced monitoring systems equipped with sensors can provide real-time data, facilitating immediate adjustments.

This meticulous control of the growing environment fosters healthy development, leading to higher yields and improved fruit quality in hydroponically cultivated squash.

Watering and Ph Levels

In hydroponic squash cultivation, maintaining an ideal watering schedule is vital to guarantee adequate nutrient uptake and prevent root diseases.

The ideal pH range for nutrient solutions should be meticulously maintained between 5.5 and 6.5 to enhance nutrient availability and absorption.

Regular monitoring and adjustments of both water frequency and pH levels are fundamental to promote vigorous growth and high yield.

Optimal Watering Schedule

Achieving an ideal watering schedule for hydroponically-grown squash necessitates careful monitoring of both nutrient solution levels and pH balance to confirm maximum growth and yield.

Utilizing automated drip or ebb-and-flow systems confirms consistent delivery of oxygenated nutrient solutions. Key parameters include maintaining solution temperature between 65-75°F to optimize nutrient uptake and prevent root disease.

Daily monitoring and adjustments are essential; excessive watering can lead to root rot, while insufficient hydration impairs nutrient absorption. Employing electronic sensors to track real-time solution levels and pH can enhance precision.

Ideal Ph Range

For ideal growth and nutrient absorption in hydroponically-grown squash, the pH of the nutrient solution should be meticulously maintained within a range of 5.5 to 6.5.

This pH range optimizes the solubility and availability of essential macro and micronutrients, ensuring efficient uptake by the plant's root system.

Deviations from this range can cause nutrient lockout, leading to deficiencies or toxicities that impede growth.

Regular monitoring using a calibrated pH meter is imperative.

Adjustments can be achieved using pH adjustment solutions, such as phosphoric acid or potassium hydroxide.

Maintaining this precise pH range not only promotes robust vegetative and fruit development but also enhances overall plant health, thereby maximizing yield potential in hydroponic squash cultivation systems.

Supporting Squash Plants

Properly supporting squash plants in a hydroponic system is vital to guarantee ideal growth and prevent damage to the heavy fruit.

Utilizing trellises, netting, or vertical supports can mitigate stem stress and enhance spatial utilization. Employing materials such as nylon or polypropylene mesh guarantees durability and resistance to hydroponic conditions.

For best results, integrate support structures early in the growth cycle to accommodate rapid vine elongation. Employing adjustable ties or clips can facilitate stem positioning and mitigate constriction risks.

Additionally, regular inspection and adjustment of support systems are important to adapt to the plant's dynamic growth patterns.

Pollination Techniques

Integral to optimizing yield in hydroponic squash cultivation, effective pollination techniques must be employed to guarantee successful fruit set and development.

In controlled environments, manual pollination is often necessary due to the absence of natural pollinators. Utilizing a fine brush or a cotton swab, transfer pollen from the male flowers to the female flowers, securing thorough contact with the stigma.

Additionally, the application of growth regulators such as gibberellic acid can enhance pollen viability and stigma receptivity.

Automated pollination systems incorporating gentle air currents or mechanical vibrators can also be integrated to simulate natural pollination processes.

These methods collectively secure robust fruit set, critical for maximizing hydroponic squash productivity and achieving consistent, high-quality yields.

Common Pests and Diseases

In hydroponic squash cultivation, vigilant monitoring and early identification of common pests and diseases are essential to maintaining plant health and ensuring peak yield. Key pests such as aphids, whiteflies, and spider mites can rapidly colonize and cause significant damage. Diseases like powdery mildew, root rot, and downy mildew further threaten plant health. Implementing Integrated Pest Management (IPM) strategies, including biological control agents and regular inspection, is vital. Below is a table summarizing common pests and diseases, their symptoms, and control measures:

| Pests/Diseases | Symptoms | Control Measures |

|---|---|---|

| Aphids | Curled leaves, sticky residue | Neem oil, ladybugs |

| Whiteflies | Yellowing leaves, leaf drop | Insecticidal soap, parasitic wasps |

| Powdery Mildew | White powdery spots on leaves | Fungicidal spray, adequate ventilation |

| Root Rot | Wilting, brown roots | Sterile growing media, proper drainage |

Effective management is imperative for ideal hydroponic squash production.

Harvesting Hydroponic Squash

When is the ideal time to harvest hydroponic squash to guarantee maximum flavor and nutritional value? Timing is essential: harvest squash when it reaches peak size and color. The ideal harvesting period usually aligns with the following indicators:

- Firmness: The squash should feel firm to the touch, indicating proper maturation.

- Color: A vibrant, consistent color without green spots suggests readiness.

- Size: For zucchini, a length of 6-8 inches is best; for other varieties, refer to specific cultivar guidelines.

These criteria assure that the hydroponic squash delivers peak flavor and nutritional benefits, embodying precision agriculture's promise of high-quality produce.

Conclusion

To summarize, the cultivation of squash through hydroponic systems presents numerous advantages, including optimized nutrient delivery, reduced pest exposure, and efficient space utilization.

What could be more compelling than the potential to achieve higher yields and superior quality in a controlled environment?

By meticulously selecting suitable squash varieties, employing effective hydroponic systems, and adhering to precise nutrient and lighting protocols, the successful production of hydroponic squash is not only feasible but also highly rewarding.