How You Can Safely Reuse Perlite in Hydroponics

Reusing perlite in hydroponics is highly beneficial, yielding substantial cost savings and aiding environmental sustainability. To guarantee its effectiveness, thorough cleaning and sterilization are essential.

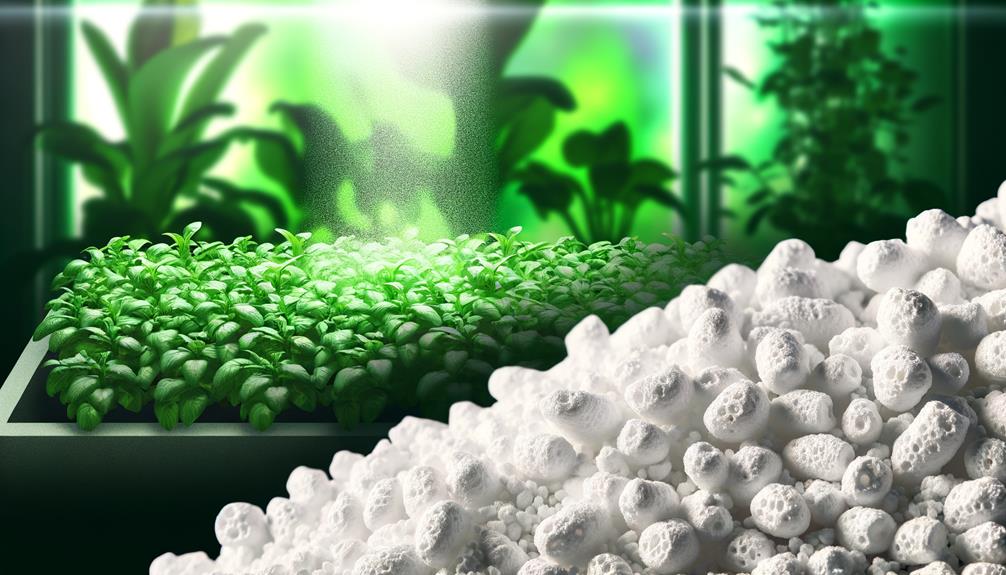

Rinsing perlite to remove organic matter and using a 10% hydrogen peroxide or diluted bleach solution for disinfection are recommended. However, over time, perlite can accumulate pathogens or degrade structurally, which may affect aeration and drainage.

Close monitoring and proper maintenance can mitigate these risks. While perlite remains a strong medium, exploring alternatives like coco coir or clay pebbles also presents viable options.

Discover the detailed procedures and considerations for optimizing reused perlite.

Key Takeaways

- Reusing perlite in hydroponics can lead to significant cost savings and environmental benefits.

- Proper cleaning and sterilization are crucial to prevent pathogen accumulation and maintain perlite effectiveness.

- Thoroughly rinse and dry perlite before reuse to retain its aeration and drainage properties.

- Regular monitoring is essential to detect and address any signs of physical degradation or nutrient imbalance.

Benefits of Reusing Perlite

Reusing perlite in hydroponic systems offers significant cost savings and environmental benefits while maintaining ideal plant growth conditions.

Perlite's inert nature and stable structure make it an excellent medium for multiple growth cycles. By reusing perlite, operational costs are reduced as the frequency of purchasing new growing media decreases.

Environmentally, the reduction in perlite waste minimizes landfill usage and conserves natural resources. Additionally, reused perlite retains its aeration and drainage properties, ensuring satisfactory oxygenation and moisture levels for root health.

This consistency in physical properties supports the robust growth and productivity of hydroponic crops. Consequently, the reuse of perlite aligns with sustainable practices, promoting both economic efficiency and environmental stewardship in advanced horticultural systems.

Cleaning and Sterilizing Perlite

Effective cleaning and sterilizing of perlite are essential steps to prevent pathogen buildup and guarantee perfect growing conditions in hydroponic systems.

Begin by thoroughly rinsing the perlite with water to remove residual organic matter and salts.

Following the rinse, submerge the perlite in a 10% hydrogen peroxide solution or a diluted bleach solution (one part bleach to nine parts water) for 20-30 minutes to eradicate any lingering pathogens.

Rinse again with clean water to eliminate chemical residues.

For added precision, consider using a pH-balanced solution to neutralize any remaining acidity or alkalinity.

Finally, allow the perlite to dry completely before reuse.

This method guarantees that perlite retains its structural integrity and aeration properties, critical for perfect plant health and growth.

Potential Risks and Drawbacks

While perlite offers numerous benefits in hydroponic systems, certain risks and drawbacks must be considered to guarantee optimal plant health and system efficiency.

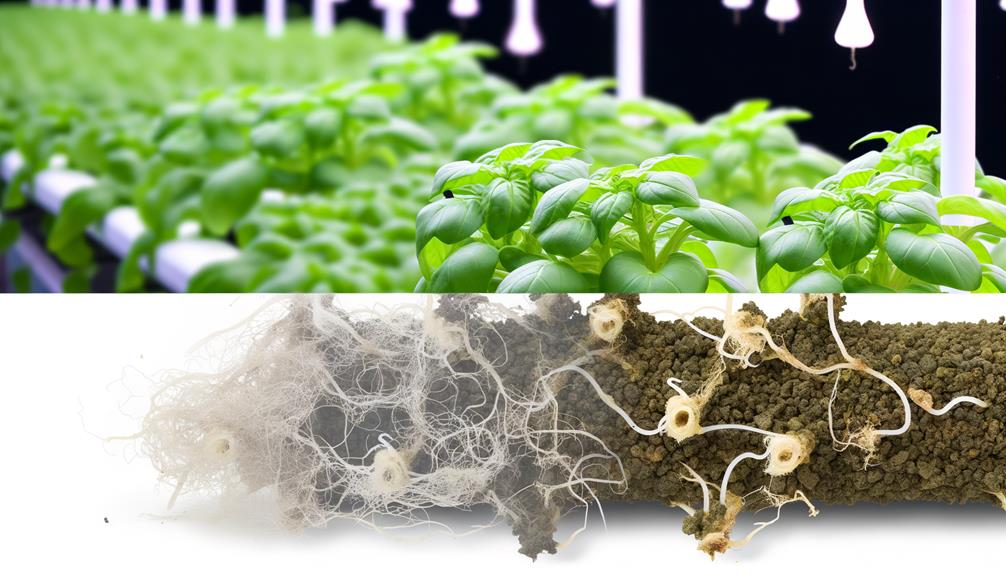

Reusing perlite can lead to the accumulation of pathogens, including fungal spores and bacteria, which may compromise plant health.

The physical structure of perlite may also degrade over time, reducing its aeration and drainage capabilities.

Additionally, residual nutrient salts can build up, altering nutrient availability and potentially causing nutrient imbalances.

Mechanical damage during cleaning processes can further diminish perlite's effectiveness.

These factors necessitate rigorous monitoring and maintenance to confirm that reused perlite does not become a vector for disease or impede ideal plant growth.

Addressing these risks is essential for maintaining high-performance hydroponic systems.

Tips for Effective Reuse

Implementing meticulous cleaning protocols and sterilization methods is vital for maximizing the longevity and effectiveness of reused perlite in hydroponic systems.

Begin by thoroughly rinsing the perlite to remove residual organic matter and salts.

Utilize a solution of hydrogen peroxide or a mild bleach solution to sterilize the medium, guaranteeing the elimination of any pathogens or contaminants.

After sterilization, make sure the perlite is completely dry before reintroducing it into the hydroponic setup.

Employing a sieve can help in removing finer particles, thereby maintaining ideal aeration and drainage properties.

Regular monitoring for signs of compaction or degradation is imperative.

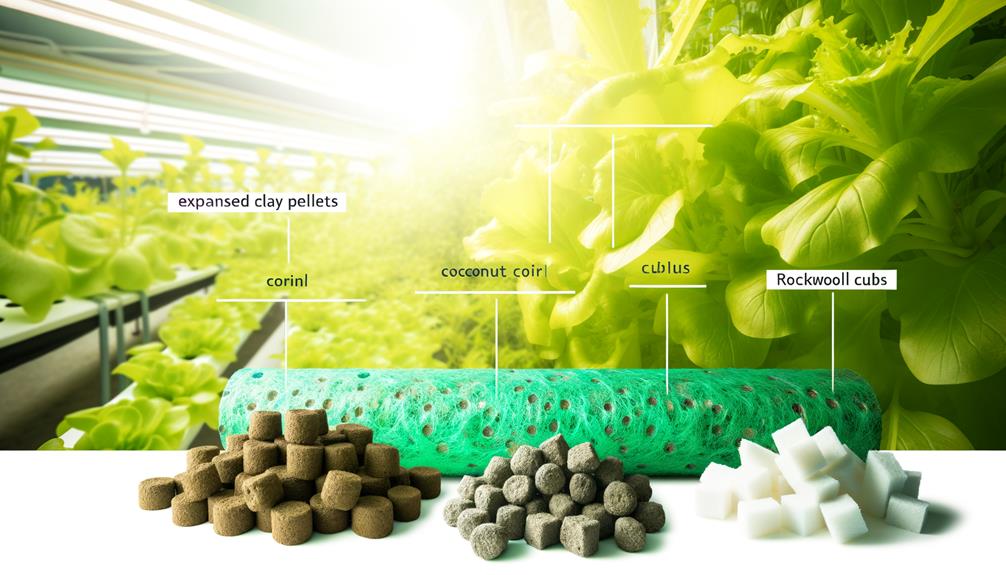

Alternatives to Perlite

For hydroponic enthusiasts seeking alternatives to perlite, several other substrates offer comparable aeration and drainage properties while catering to specific growing needs. Coco coir, rockwool, and clay pebbles are prominent substitutes, each with distinct advantages. Coco coir provides excellent water retention and microbial support. Rockwool offers superior root aeration and uniform moisture distribution. Clay pebbles guarantee ideal drainage and reusability. Here's a comparative overview:

| Substrate | Key Benefits |

|---|---|

| Coco Coir | Water retention, microbial support |

| Rockwool | Root aeration, moisture uniformity |

| Clay Pebbles | Drainage, reusability |

| Vermiculite | High water retention, aeration |

| Peat Moss | Organic, nutrient retention |

These alternatives cater to diverse hydroponic setups, enabling precise control over plant growth conditions, enhancing productivity, and fostering sustainability.

Conclusion

Reusing perlite in hydroponics can yield significant benefits, including cost savings and environmental sustainability.

Proper cleaning and sterilization are imperative to mitigate risks such as pathogen contamination.

An interesting statistic reveals that reusing perlite can reduce annual hydroponic substrate costs by up to 30%.

However, growers must weigh the potential drawbacks and consider alternatives to optimize plant health and growth.

Effective reuse of perlite demands stringent adherence to best practices to guarantee continued efficacy.