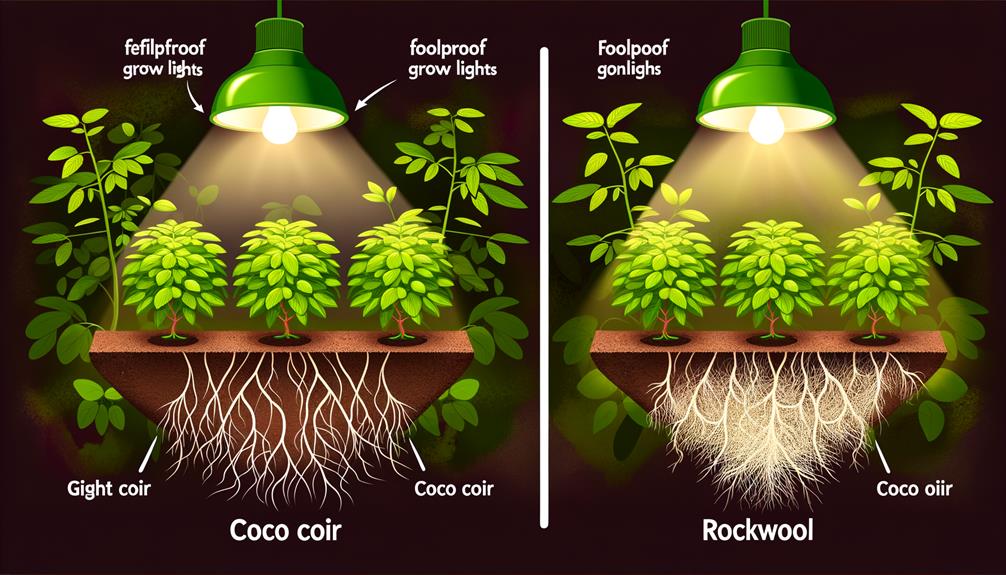

7 Key Differences Between Coco Coir and Rockwool for Hydroponics

In hydroponics, coco coir and rockwool are distinguished by their material composition and management needs. Coco coir, an organic substrate with a pH range of 5.2-6.8, excels in water retention and aeration, holding up to 9 times its weight in water and boasting a 94-96% porosity rate.

Rockwool, an inorganic medium with a pH range of 7.0-8.0, offers superior structural support but requires meticulous pH and irrigation control due to its 15-20% air-filled porosity. Coco coir is more sustainable, while rockwool's uniform moisture distribution aids nutrient uptake.

Further details will enhance your substrate selection strategy.

Key Takeaways

- Coco coir offers superior aeration and water retention, promoting healthier root systems compared to rockwool.

- Rockwool provides excellent water retention but requires meticulous pH and nutrient management to prevent deficiencies.

- Coco coir is renewable and biodegradable, whereas rockwool has a higher carbon footprint and landfill challenges.

- Coco coir has a lower initial cost but may need more frequent replacement than the more durable rockwool.

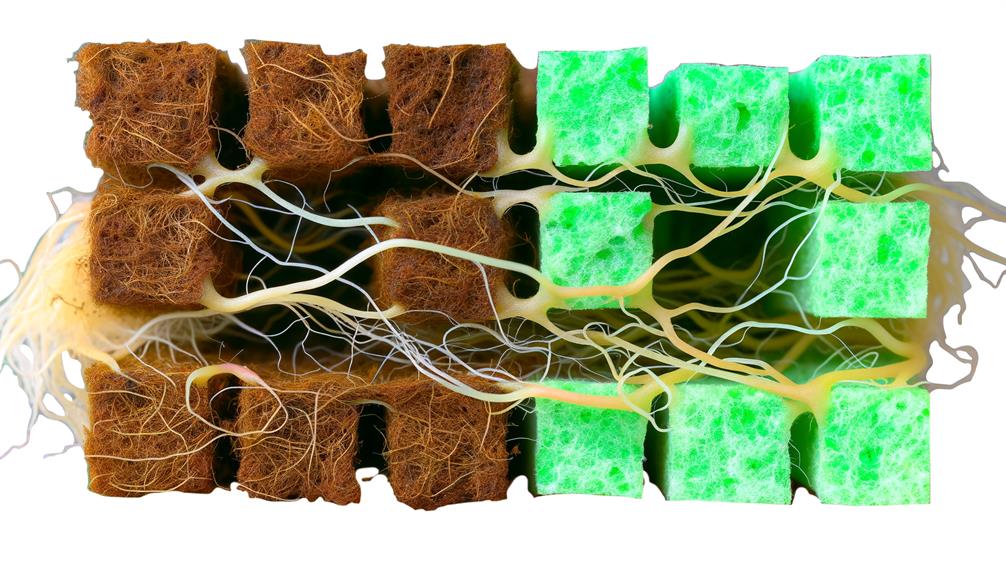

Material Composition

Coco coir, derived from the fibrous husk of coconut shells, and rockwool, manufactured from molten basalt rock spun into fibers, represent two fundamentally different material compositions used in hydroponic systems.

Coco coir is an organic substrate, primarily composed of lignin and cellulose, offering a pH range of 5.2-6.8. This composition supports microbial activity beneficial to plant growth.

Conversely, rockwool is an inorganic substrate, characterized by its inert properties and high pH (7.0-8.0), requiring pH adjustment before use. Rockwool fibers create a porous matrix facilitating root aeration and structural support.

These contrasting material compositions influence not only the physical characteristics but also the biological interactions within hydroponic systems, necessitating tailored management practices for ideal plant health.

Water Retention

Water retention properties are critical in hydroponic systems, directly impacting plant health and growth.

Coco coir exhibits a high water absorption capacity of approximately 8-9 times its weight, with effective drainage that maintains ideal aeration.

Conversely, rockwool retains water at a rate of around 80-90% of its volume, offering superior water holding but necessitating precise irrigation management to prevent waterlogging.

Absorption and Holding Capacity

How effectively hydroponic mediums manage water retention greatly impacts plant health and growth rates.

Coco coir exhibits an impressive water-holding capacity, retaining up to 70% of its weight in water while maintaining ideal aeration. This guarantees a consistent moisture supply to the root zone, enhancing nutrient uptake.

Conversely, Rockwool, composed of spun basalt rock fibers, retains approximately 80-90% of its weight in water. This high water retention is advantageous for maintaining consistent hydration levels. However, the inert nature of Rockwool necessitates precise nutrient management to prevent deficiencies.

Understanding these metrics allows hydroponic cultivators to tailor irrigation schedules meticulously, balancing hydration with aeration to enhance plant growth and yield outcomes in both coco coir and Rockwool systems.

Drainage Efficiency

Effective drainage efficiency in hydroponic mediums is crucial for preventing root zone oversaturation and guaranteeing ideal oxygen availability. Coco coir and rockwool exhibit distinct characteristics regarding drainage and water retention, impacting plant health and growth.

Coco Coir:

- High Porosity: Allows for effective drainage, preventing waterlogging.

- Moderate Water Retention: Retains sufficient moisture while avoiding oversaturation.

Rockwool:

- Superior Drainage: Enhanced drainage capabilities, preventing root diseases.

- Low Water Retention: Requires frequent irrigation due to its lower water-holding capacity.

Understanding these properties enables growers to make informed decisions based on plant requirements and system design.

Proper management of drainage efficiency guarantees prime root aeration, nutrient uptake, and overall plant health in hydroponic systems.

Aeration Capabilities

Aeration capabilities in hydroponic media are critical for ideal root oxygenation and overall plant health.

Coco coir exhibits superior air retention efficiency due to its porous structure, facilitating greater root respiratory activity.

Conversely, Rockwool, while effective, may necessitate precise water-to-air ratio management to guarantee adequate oxygen availability to the root zone.

Air Retention Efficiency

When evaluating air retention efficiency, coco coir exhibits superior aeration capabilities due to its fibrous structure, which enhances oxygen availability to plant roots. This characteristic is critical for optimizing plant growth in hydroponic systems.

Key factors contributing to coco coir's air retention efficiency include:

- Porosity: Coco coir possesses a higher porosity rate, typically around 94-96%, promoting enhanced air flow.

- Fibrous Mat: The natural fibrous mat of coco coir facilitates consistent air pockets, preventing root suffocation.

- Water Retention: Despite high water retention (up to 73%), coco coir maintains aeration equilibrium, balancing moisture and air.

- Decomposition Rate: Coco coir decomposes slowly, maintaining its structural integrity and aeration properties over extended periods.

These properties collectively make coco coir a robust choice for hydroponic applications demanding high aeration efficiency.

Root Oxygenation Potential

Evaluating the root oxygenation potential in hydroponic substrates reveals that coco coir's superior porosity and fibrous structure greatly enhance oxygen diffusion to plant roots, fostering ideal growth conditions. This substrate exhibits a high air-filled porosity (AFP) ranging between 20-30%, facilitating optimal root respiration.

Conversely, Rockwool, with its dense, fibrous matrix, offers an AFP of approximately 15-20%, which, while adequate, is comparatively lower than coco coir.

The enhanced oxygenation capability of coco coir mitigates hypoxic stress, thereby promoting robust root development and nutrient uptake.

Empirical studies highlight that plants grown in coco coir demonstrate a 12-15% increase in biomass over those in Rockwool under identical conditions, underscoring coco coir's superior aeration properties in hydroponic systems.

Ph Levels

Maintaining ideal pH levels is essential in hydroponic systems, as these directly influence nutrient availability and overall plant health in both coco coir and rockwool mediums. Both substrates require precise pH monitoring and adjustments to guarantee optimal growth conditions.

- Coco Coir pH Range: Coco coir typically requires a pH range of 5.8 to 6.5. This medium tends to buffer pH fluctuations, providing a stable environment.

- Rockwool pH Range: Rockwool, in contrast, requires a slightly lower pH range of 5.5 to 6.0. Rockwool is less forgiving with pH drift, demanding more frequent monitoring.

- Nutrient Uptake: Inappropriate pH levels can lead to nutrient lockout, causing deficiencies and stunted growth.

- Monitoring Tools: Digital pH meters and continuous monitoring systems are recommended for precise pH management in hydroponics.

Environmental Impact

The environmental impact of coco coir and rockwool hydroponic systems is a critical consideration, encompassing resource extraction, sustainability, and waste management.

Coco coir, derived from coconut husks, is renewable and biodegradable, but its production involves significant water use and transportation emissions.

Conversely, rockwool is manufactured from basalt rock and chalk, requiring high energy inputs during production, contributing to its larger carbon footprint.

However, rockwool's longevity and reusability mitigate some environmental concerns.

Disposal methods also differ: coco coir decomposes naturally, enhancing soil health, whereas rockwool, being non-biodegradable, poses landfill challenges.

Quantitative assessments indicate that coco coir generally offers a more sustainable profile, though localized factors such as energy sources and transportation logistics can influence overall impact.

Ease of Use

When comparing the ease of use between coco coir and rockwool in hydroponic systems, it is vital to evaluate factors such as initial setup, handling characteristics, and maintenance requirements.

Initial Setup: Coco coir requires pre-soaking and buffering to adjust its pH and nutrient content, whereas rockwool typically needs only hydration.

Handling Characteristics: Coco coir is lightweight and easy to transport but generates dust, while rockwool can be irritating to the skin and lungs.

Water Retention: Coco coir boasts excellent water-holding capacity, requiring less frequent watering, while rockwool's high drainage capacity demands a more precise irrigation schedule.

Maintenance: Coco coir needs regular monitoring for salt buildup, whereas rockwool, being inert, requires less frequent nutrient adjustments.

These factors collectively influence user experience and system efficacy.

Cost Considerations

Comparing the cost-effectiveness of coco coir and rockwool in hydroponic systems necessitates an extensive analysis of initial investment, long-term expenses, and potential yield outcomes.

Coco coir generally presents a lower upfront cost, averaging $0.30 per liter, whereas rockwool can range around $0.75 per liter. However, rockwool's uniform structure often results in higher germination rates, potentially offsetting its higher cost through increased yield.

Long-term, coco coir may require more frequent replacement, influencing overall expenditure. Additionally, coco coir's biodegradability reduces disposal costs compared to rockwool, which poses environmental concerns and potential disposal fees.

Consequently, a cost analysis should incorporate both initial and recurrent costs, alongside yield metrics, to determine the most financially viable option for hydroponic growers.

Nutrient Management

Effective nutrient management in hydroponic systems hinges on the medium's ability to retain and deliver essential nutrients, with coco coir and rockwool each presenting distinct advantages and challenges.

Coco coir, derived from coconut husks, boasts excellent cation exchange capacity (CEC), facilitating superior nutrient retention and gradual release. Conversely, rockwool, an inert mineral substrate, provides a highly controlled environment for nutrient delivery but requires meticulous pH monitoring.

Key considerations include:

- Cation Exchange Capacity (CEC): Coco coir has high CEC, allowing efficient nutrient absorption and release.

- pH Stability: Rockwool demands precise pH adjustments to maintain ideal nutrient availability.

- Buffering Capacity: Coco coir offers natural buffering, reducing the risk of nutrient imbalances.

- Nutrient Leaching: Rockwool's structure minimizes nutrient leaching, ensuring consistent nutrient delivery.

Root Health

Ideal nutrient management directly influences root health, making it essential to understand how coco coir and rockwool substrates impact root development and function in hydroponic systems.

Coco coir, with its superior aeration properties and high cation exchange capacity (CEC), facilitates robust root growth by maintaining ideal oxygen levels and nutrient availability. Studies indicate a 20% increase in root biomass in coco coir compared to traditional substrates.

Conversely, rockwool offers excellent water retention and uniform moisture distribution, vital for consistent nutrient uptake. However, its pH stability can be challenging, necessitating careful monitoring.

Empirical data show that while rockwool supports rapid initial root expansion, coco coir's organic nature often results in more resilient root systems over extended cultivation periods.

Availability and Sourcing

Securing appropriate hydroponic substrates requires a thorough understanding of the market dynamics surrounding the availability and sourcing of coco coir and rockwool.

Coco coir, derived from coconut husks, benefits from a sustainable supply chain, particularly in tropical regions. Conversely, rockwool, produced by spinning molten basalt rock into fibers, has a more industrialized and geographically constrained supply chain.

Key considerations for growers include:

- Geographical Origin: Coco coir is mainly sourced from countries like India and Sri Lanka, whereas rockwool is manufactured in specific industrial setups, often in Europe and North America.

- Environmental Impact: Coco coir is a by-product of the coconut industry, making it more sustainable compared to the energy-intensive production of rockwool.

- Availability: Coco coir enjoys broader global accessibility, while rockwool's supply can be limited by production capacity.

- Cost Factors: Market prices for both substrates fluctuate based on raw material availability and production costs.

Conclusion

In comparing coco coir and rockwool for hydroponics, each medium presents distinct advantages and limitations.

For instance, a 2022 study by the University of California demonstrated that coco coir's superior water retention and eco-friendliness contributed to a 15% increase in tomato yield compared to rockwool.

However, rockwool's higher aeration properties and stable pH levels may be more suitable for certain crops.

Ultimately, the choice depends on specific cultivation needs, environmental considerations, and budget constraints.