3 Simple Steps to Building Your Own DIY Hydroponic Tower Grow System

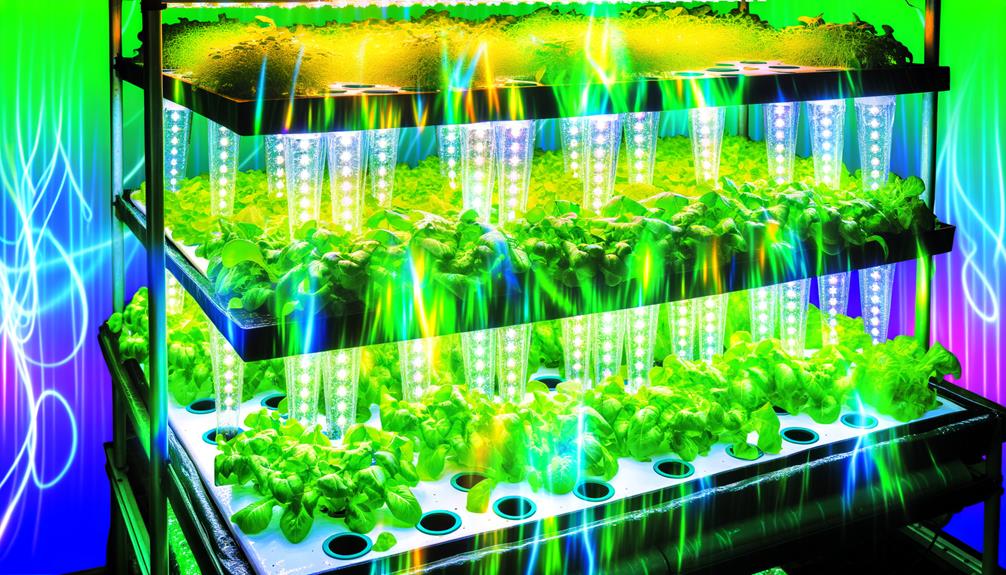

Creating a DIY hydroponic tower grow system maximizes vertical space and optimizes the nutrient delivery, vital for urban farming. This soil-less method employs nutrient-rich water solutions, enhancing plant health by controlling pH levels and electrical conductivity.

Essential materials include a food-grade nutrient reservoir, submersible water pump, rock wool or clay pellets, and net pots. High-yield plants such as leafy greens and herbs thrive in this controlled environment.

Precise nutrient management, regular monitoring of pH and EC, and proper aeration are critical. To fully master the intricate details, following structured guidelines will guarantee a successful setup.

Key Takeaways

- A hydroponic tower maximizes vertical space, increasing yield and efficiency in urban settings.

- Essential materials include PVC pipes, a submersible pump, net pots, and a nutrient solution reservoir.

- Regularly monitor pH (5.5-6.5) and electrical conductivity for optimal plant growth.

- Leafy greens, herbs, and strawberries are ideal choices for hydroponic systems.

Understanding Hydroponics

Understanding hydroponics involves examining the science of growing plants without soil by using nutrient-rich water solutions to deliver essential minerals directly to the plant roots. This method leverages principles of fluid dynamics and plant physiology to optimize growth conditions.

By precisely controlling pH levels, electrical conductivity, and nutrient concentrations, hydroponic systems can greatly enhance plant health and yield. The absence of soil mitigates risks of soil-borne diseases and pests, while also facilitating efficient water usage.

Innovations in hydroponic technology, such as aeroponics and nutrient film technique (NFT), further refine the delivery of nutrients and oxygen to plant roots. Understanding these complex interactions is essential for designing and implementing effective hydroponic systems, particularly in constrained urban environments where traditional agriculture is impractical.

Benefits of a Tower System

The hydroponic tower system offers significant advantages, particularly in maximizing vertical space utilization and achieving water conservation efficiency.

By employing a vertical structure, these systems enable the cultivation of a greater number of plants per square foot compared to traditional horizontal layouts.

Additionally, the closed-loop water recirculation mechanism enhances water use efficiency, thereby reducing overall water consumption and promoting sustainable agricultural practices.

Maximizes Vertical Space

By utilizing a vertical design, hydroponic tower grow systems greatly enhance space efficiency, enabling the cultivation of a higher plant density within a constrained footprint. This innovative approach is particularly advantageous for urban environments where horizontal space is at a premium. The vertical configuration allows for multiple tiers of plant growth, optimizing light exposure and nutrient distribution.

Key benefits include:

- Increased Yield: Maximizing vertical space translates to more plants per square foot, markedly boosting overall yield potential.

- Optimal Resource Utilization: Enhanced light penetration and air circulation lead to healthier, more robust plants.

- Scalability: The modular nature of hydroponic towers facilitates easy expansion, catering to both small-scale hobbyists and large-scale commercial operations.

This methodological advancement represents a paradigm shift in modern agricultural practices.

Conserves Water Efficiently

Hydroponic tower grow systems exhibit exceptional water conservation capabilities by recirculating nutrient solutions, thereby minimizing water wastage and ensuring efficient resource utilization.

This closed-loop system reduces the need for frequent water replenishment, as the same solution can be reused multiple times.

Unlike traditional soil-based agriculture, where water loss due to evaporation and runoff is significant, tower systems contain and direct water precisely to plant roots.

Advanced monitoring technologies further enhance water use efficiency by adjusting flow rates based on real-time data.

Essential Materials

Assembling a functional hydroponic tower grow system necessitates procuring a precise array of specialized materials designed to support efficient nutrient delivery and ideal plant growth. This includes selecting a durable frame, an appropriate pump for consistent water circulation, and nutrient-rich solutions tailored to the specific crops being cultivated. For growers seeking a more discreet setup, incorporating a DIY stealth hydroponic grow box can help maintain a low-profile system while optimizing space and resource efficiency. Careful assembly and regular maintenance ensure that plants receive the necessary nutrients and oxygen, leading to healthy and rapid growth.

The following components are integral to the construction and operation of a high-performance hydroponic setup:

- Nutrient Solution Reservoir: Essential for housing nutrient-rich water, this reservoir must be constructed from food-grade materials to prevent contamination and guarantee long-term durability.

- Submersible Water Pump: Crucial for circulating the nutrient solution through the tower, a reliable, high-capacity pump guarantees consistent delivery of nutrients to all plant tiers.

- Grow Medium: Unlike soil, this inert medium (e.g., rock wool, clay pellets) provides structural support while facilitating optimal root aeration and nutrient absorption, critical for plant health and growth efficiency.

These components collectively form the backbone of an innovative hydroponic system.

Choosing the Right Plants

Selecting the appropriate plant species is essential to maximizing the efficiency and yield of your hydroponic tower grow system.

Ideal choices include leafy greens such as lettuce, spinach, and kale, which thrive in nutrient-rich, water-based environments.

Herbs like basil, mint, and cilantro also exhibit robust growth in hydroponic setups due to their minimal root space requirements and rapid growth cycles.

For more advanced cultivators, strawberries and dwarf tomatoes can be integrated, provided they receive adequate light and nutrient management.

It is vital to evaluate each plant's growth habit, root structure, and nutrient needs to guarantee compatibility with vertical hydroponic systems.

Building the Structure

Constructing the hydroponic tower necessitates a precise selection of materials and tools to guarantee structural integrity and ideal plant growth conditions.

The assembly of the framework involves detailed steps, including precise measurements, secure fastening, and strategic placement of components to facilitate nutrient delivery and support plant weight.

This section will thoroughly outline the required materials and tools, followed by a methodical guide to assembling the framework.

Materials and Tools Needed

To build the structure of a robust hydroponic tower grow system, it is essential to gather specific materials and tools that guarantee stability and optimal plant growth. Precision and quality are paramount to guarantee the longevity and effectiveness of the system.

Key materials and tools include:

- PVC Pipes and Fittings: Essential for constructing the primary framework, providing a lightweight yet durable structure.

- Submersible Pump: Critical for maintaining consistent nutrient flow, guaranteeing peak plant hydration and nutrient uptake.

- Net Pots and Grow Media: Integral for supporting plant roots while facilitating efficient nutrient absorption and aeration.

Utilizing these components will form the backbone of a hydroponic tower, fostering an environment where plants can thrive through advanced hydroponic techniques.

Assembling the Framework

Initiating the assembly of the hydroponic tower framework involves methodically connecting the PVC pipes and fittings to create a stable and efficient structure for plant cultivation.

Begin by measuring and cutting the PVC pipes to the specified lengths. Utilize a PVC cutter for precision and smooth edges.

Employ T-joints and elbow fittings to form the vertical and horizontal supports, guaranteeing each connection is securely bonded using PVC cement for structural integrity.

Incorporate cross braces to enhance stability and evenly distribute weight.

Additionally, drill appropriately sized holes for net pots at strategic intervals along the vertical pipes to facilitate ideal plant spacing and nutrient distribution.

This meticulous assembly guarantees robust support and maximized growth potential within the hydroponic system.

Setting Up the Reservoir

Properly configuring the nutrient reservoir is critical for guaranteeing ideal water and nutrient delivery to your hydroponic tower grow system. To achieve optimal results, follow these advanced guidelines:

- Reservoir Capacity: Confirm the reservoir has sufficient volume to sustain your plants, ideally calculated by plant water uptake rates and system size. An inadequate reservoir could lead to nutrient imbalances and water stress.

- Nutrient Solution Preparation: Utilize precise measurements and high-quality hydroponic nutrients. The solution's electrical conductivity (EC) and pH levels must be meticulously monitored and adjusted to foster optimal plant growth.

- Aeration: Enhance oxygen availability in the nutrient solution by incorporating an air pump and air stones. This prevents anaerobic conditions and supports root respiration, leading to healthier plant development.

Meticulous attention to these aspects guarantees a robust foundation for your hydroponic system.

Installing the Pump

Securing the pump within your hydroponic tower grow system involves strategically positioning it to guarantee efficient nutrient solution circulation and consistent delivery to all plant roots. Begin by selecting a submersible pump with a flow rate compatible with your system's height and plant density. Position the pump at the base of the reservoir, making sure it is firmly anchored to avoid displacement. Connect the tubing securely, making sure there are no leaks to maintain ideal pressure.

| Component | Specification |

|---|---|

| Pump Type | Submersible |

| Flow Rate | 250-400 GPH |

| Tubing Material | Food-grade PVC |

| Tubing Diameter | 1/2 inch |

Precision in installation is paramount to prevent pump cavitation and guarantee a seamless nutrient delivery, fostering a robust growth environment.

Managing Nutrient Solutions

Effective management of nutrient solutions is vital to guarantee the best plant growth and maximize the productivity of your hydroponic tower grow system. Confirming the correct balance of macro and micronutrients, maintaining ideal pH levels, and monitoring electrical conductivity (EC) are critical.

Nutrient Composition: Utilize a well-formulated hydroponic nutrient solution that includes essential elements like nitrogen, phosphorus, and potassium, as well as trace elements such as iron and magnesium.

pH Levels: Regularly check and adjust the pH of your nutrient solution to maintain a range between 5.5 and 6.5, which is ideal for nutrient uptake.

Electrical Conductivity (EC): Monitor EC levels to confirm nutrient concentration remains within the best range, preventing deficiencies or toxicities.

Maintenance and Troubleshooting

Regular maintenance and systematic troubleshooting are imperative for ensuring the longevity and peak functionality of your hydroponic tower grow system. Conducting routine inspections of key components such as pumps, nutrient delivery lines, and water reservoirs is essential. Address any signs of wear, blockages, or leaks promptly to mitigate potential disruptions. Implementing a schedule for pH and electrical conductivity (EC) monitoring will help maintain ideal nutrient absorption rates.

| Issue | Possible Cause | Solution |

|---|---|---|

| Low Water Flow | Clogged Pump or Tubing | Clean or replace affected parts |

| Yellowing Leaves | Nutrient Imbalance or pH Fluctuation | Adjust nutrient solution and pH levels |

| Algae Growth | Excess Light Exposure | Shield reservoir from light |

| Root Rot | Poor Aeration | Increase oxygenation in nutrient solution |

Regular diagnostics facilitate preemptive measures, preserving system efficiency.

Conclusion

To summarize, constructing a DIY hydroponic tower grow system offers substantial advantages, including space efficiency and enhanced plant growth rates.

By meticulously selecting materials, optimizing the reservoir and pump setup, and managing nutrient solutions, cultivators can achieve superior outcomes.

As the adage goes, 'A stitch in time saves nine,' emphasizing the importance of regular maintenance and troubleshooting to guarantee system longevity and productivity.

Mastery of these elements can lead to a highly productive and sustainable method of cultivation.