3 Simple Steps to Build a DIY Stealth Hydroponic Grow Box

Building a DIY stealth hydroponic grow box involves designing an advanced, compact system ideal for discreet urban cultivation. Key components include high-efficiency LED grow lights for peak photosynthesis, a nutrient reservoir integrated with a water pump for consistent delivery, and air pumps for solution aeration.

Essential elements such as carbon filters and ventilation fans guarantee effective odor control, while UV-resistant materials prevent algae growth. Constructing a robust frame using galvanized steel or treated lumber adds structural integrity.

Automated systems for nutrient management and environmental control are pivotal for maintaining plant health. Explore further to refine your growing strategy.

Key Takeaways

- Opt for a compact, modular design to fit urban spaces and allow for scalable expansion.

- Use high-efficiency LED grow lights and carbon filters to reduce visibility and control odor.

- Construct the frame with galvanized steel or treated lumber for durability and structural integrity.

- Ensure light-proofing with opaque materials and reflective coatings to prevent algae growth.

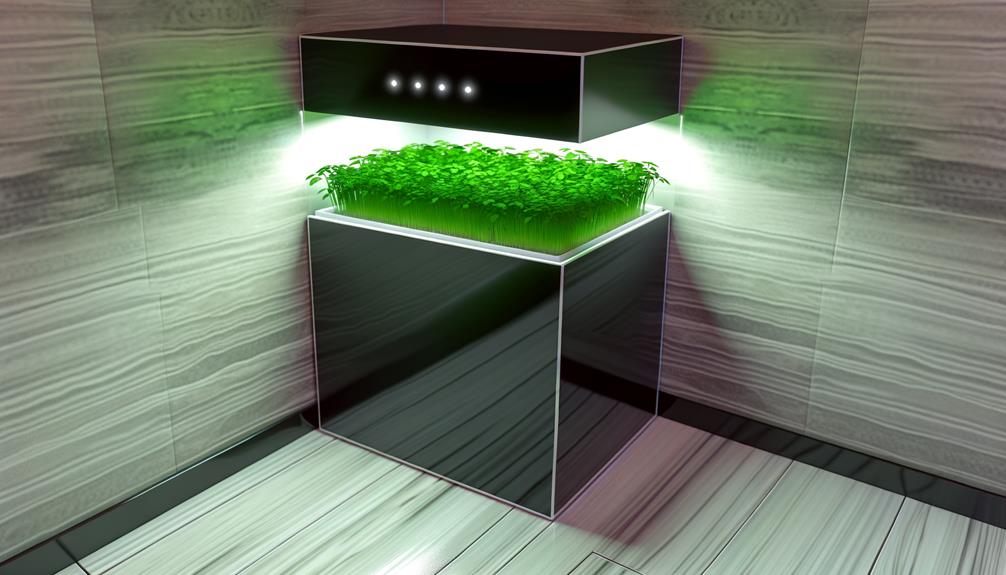

Benefits of a Stealth Grow Box

Why is a stealth grow box particularly advantageous for urban horticulturists seeking to maximize space efficiency and minimize detection risks?

A stealth grow box offers a compact, inconspicuous solution, blending seamlessly into limited urban environments while optimizing spatial usage.

This innovation employs high-efficiency LED systems and odor-neutralizing carbon filters, ensuring minimal visibility and olfactory detection.

Integrating advanced hydroponic techniques, it provides a controlled, soilless medium fostering accelerated plant growth and enhanced yield.

The box's design incorporates sound-dampening materials and light-proofing mechanisms, maintaining stealth operation.

Additionally, its modular nature allows for scalable expansion, adapting to varying cultivation demands.

Accordingly, a stealth grow box epitomizes the intersection of discretion and efficiency, essential for urban agricultural pursuits amid spatial and regulatory constraints.

Essential Materials

To construct a highly efficient DIY hydroponic grow box, one must acquire a precise selection of specialized materials, each integral to guaranteeing ideal plant growth and system functionality. This includes choosing the right grow lights, nutrient solutions, and a reliable water circulation system to maintain optimal conditions. Proper ventilation and humidity control are also crucial to prevent mold and ensure healthy plant development. With careful planning and execution, a DIY hydroponic weed grow can yield impressive results while maximizing space and efficiency.

Key components include high-intensity LED grow lights for peak photosynthetic efficiency, a nutrient reservoir to supply essential macro and micronutrients, and a water pump to maintain consistent nutrient circulation.

Additionally, an air pump with air stones is crucial for oxygenating the nutrient solution. Reflective Mylar sheets enhance light distribution, while pH and EC meters are indispensable for monitoring solution parameters.

A carbon filter paired with a ventilation fan guarantees odor control and air exchange.

Choosing the Right Container

Selecting an appropriate container for a hydroponic grow box necessitates careful consideration of size and space requirements to accommodate root expansion and plant growth.

The material must exhibit robustness and resistance to degradation, ensuring long-term operational efficacy.

Additionally, implementing light-proofing techniques is essential to prevent algae proliferation and maintain ideal root zone conditions.

Size and Space Requirements

Determining the ideal container for a DIY hydroponic grow box necessitates a detailed analysis of spatial constraints, plant root architecture, and nutrient delivery systems.

Adequate space must be allocated for both vertical and horizontal root expansion to prevent entanglement and guarantee optimal nutrient absorption. The volumetric capacity of the container should facilitate a robust nutrient solution reservoir, maintaining consistent pH and electrical conductivity levels.

Additionally, consider the integration of aeration mechanisms to enhance oxygenation within the root zone, thereby promoting vigorous plant growth.

Modular designs can offer flexibility in accommodating various plant sizes and growth stages, while guaranteeing efficient utilization of space.

Precision in container selection directly influences the efficacy of the hydroponic system and the overall yield.

Material and Durability

The selection of materials for a DIY hydroponic grow box must prioritize durability, chemical inertness, and resistance to environmental stressors to guarantee long-term system integrity and ideal plant health.

High-density polyethylene (HDPE) and food-grade polypropylene (PP) are excellent choices due to their robustness and non-reactive properties. These materials resist UV degradation and are impermeable to moisture, ensuring structural stability and preventing nutrient solution contamination.

Additionally, selecting containers with reinforced corners and smooth surfaces will minimize microbial growth and facilitate easy cleaning.

Employing materials that withstand high humidity, temperature fluctuations, and potential physical impacts is essential.

Light-proofing Techniques

Making certain the hydroponic grow box remains light-proof is essential to prevent algae growth and maintain ideal root zone conditions. This necessitates the selection of containers designed with opaque, light-blocking materials.

Containers fabricated from high-density polyethylene (HDPE) or similar polymers are best due to their inherent durability and light-impermeable properties. Additionally, reflective coatings on the interior can also reduce any incidental light penetration, enhancing the system's overall efficacy.

Employing containers with tightly fitted, light-sealed lids is vital to eliminate any potential light leakage. Moreover, integrating UV-resistant materials can prolong the container's lifespan by preventing degradation from ambient light exposure.

These precise considerations guarantee a maximally efficient, algae-free hydroponic environment conducive to robust plant growth.

Setting Up the Frame

Constructing the frame for your DIY hydroponic grow box necessitates meticulous planning and precise execution to guarantee structural integrity and ideal functionality.

Utilize high-quality materials such as galvanized steel or treated lumber to assure durability and resistance to environmental factors.

Employ accurate measurements and cutting techniques to create a sturdy base and vertical supports.

Reinforce joints with metal brackets or wood screws to prevent structural failure.

Incorporate adjustable shelving to accommodate varying plant heights, optimizing growth conditions.

Ascertain the frame's dimensions align with the intended grow space, allowing for adequate ventilation and accessibility.

Attention to these technical specifics will establish a robust framework, laying the groundwork for an efficient and high-performing hydroponic system.

Installing the Hydroponic System

Initiating the installation of the hydroponic system demands an intricate understanding of nutrient delivery mechanisms and fluid dynamics to guarantee ideal plant growth and efficiency.

Begin by integrating a reliable water reservoir, making certain it is equipped with a submersible pump capable of maintaining consistent nutrient solution circulation.

Utilize high-quality tubing to facilitate uninterrupted flow between the reservoir and the grow tray.

Employ an air stone connected to an air pump to oxygenate the nutrient solution, thereby preventing anaerobic conditions detrimental to root health.

Precisely calibrate a nutrient delivery schedule through an automated timer to guarantee maximum nutrient uptake.

Lighting and Ventilation

Once the hydroponic system is properly installed, the implementation of a perfect lighting and ventilation setup becomes imperative to foster robust plant growth and prevent environmental stressors. High-efficiency LED grow lights are recommended to provide a full spectrum of light, mimicking natural sunlight and promoting photosynthesis. Furthermore, ensuring proper ventilation is critical to regulate temperature and humidity levels, preventing mold growth and heat stress.

| Component | Function |

|---|---|

| LED Grow Lights | Full spectrum lighting, energy efficiency |

| Inline Fans | Facilitates air circulation, temperature control |

| Carbon Filters | Removes impurities, maintains air quality |

Advanced ventilation systems should incorporate inline fans and carbon filters to maintain ideal air quality, essential for plant health and productivity.

Odor Control Solutions

Effective odor control in a hydroponic grow box necessitates the integration of activated carbon filters, which adsorb volatile organic compounds and mitigate olfactory emissions.

Additionally, employing odor neutralizing agents can biochemically alter or mask undesirable scents.

Optimizing air circulation systems further guarantees the even dispersion of clean air, maintaining an environment conducive to plant health and growth while minimizing odor accumulation.

Activated Carbon Filters

Activated carbon filters are indispensable components for odor control in hydroponic grow boxes, leveraging their high surface area and adsorption capabilities to effectively neutralize volatile organic compounds (VOCs) and other malodorous substances.

These filters operate through a sophisticated mechanism involving the physical adsorption of molecules onto activated carbon granules. The efficacy of this system can be attributed to the following factors:

- Surface Area: Activated carbon boasts an expansive surface area, typically exceeding 1,000 m²/g, facilitating extensive molecular interactions.

- Porosity: The presence of micro-, meso-, and macropores guarantees a broad range of contaminant capture.

- Adsorption Capacity: High adsorption capacity enables prolonged use before saturation.

- Regeneration Potential: Some activated carbon filters offer regeneration capabilities, enhancing sustainability.

Utilizing these advanced filtration systems guarantees ideal odor control, essential for maintaining a discrete hydroponic environment.

Odor Neutralizing Agents

In addition to activated carbon filters, odor neutralizing agents serve as a complementary odor control solution by chemically altering or encapsulating malodorous molecules, thereby enhancing the overall efficiency of hydroponic grow box air management systems.

These agents typically employ advanced formulations, such as essential oil-based neutralizers or ozone generators, which target volatile organic compounds (VOCs) responsible for odor.

The integration of these agents into the grow box environment can greatly diminish olfactory detection, ensuring a more discreet operation.

Essential oil-based neutralizers work through adsorption and neutralization processes, while ozone generators oxidize odor-causing compounds at a molecular level.

Utilizing such sophisticated odor neutralizing agents augments the efficacy of existing filtration systems, offering a multi-faceted approach to maintaining a superior growing atmosphere.

Air Circulation Systems

Optimizing air circulation systems is paramount for effective odor control within hydroponic grow boxes, guaranteeing the continuous removal of stale air and the introduction of fresh, filtered air to maintain ideal growing conditions.

Advanced air circulation solutions integrate cutting-edge technologies to mitigate unwanted odors and enhance plant health.

Consider the following components:

- Activated Carbon Filters: Utilized to adsorb volatile organic compounds (VOCs) and neutralize odors.

- Inline Fans: Essential for maintaining airflow, these fans guarantee continuous air exchange, preventing stagnation.

- Ozone Generators: These devices oxidize odor-causing molecules, providing a sterile environment.

- Ducting Systems: Strategically positioned ducts promote prime air distribution, enhancing the efficacy of the entire ventilation system.

Implementing these elements will noticeably elevate the performance of your hydroponic setup.

Nutrient Solutions and Watering

Proper management of nutrient solutions and watering protocols is essential to guaranteeing ideal plant growth and health within a hydroponic grow box system.

Precision in the formulation of nutrient solutions is vital; plants require a balanced mix of macronutrients (N, P, K) and micronutrients (Fe, Mn, Zn) to maximize photosynthesis and metabolic functions.

Employing an automated drip irrigation or nutrient film technique (NFT) can enhance efficiency by providing consistent hydration and nutrient delivery.

Electrical conductivity (EC) and pH levels should be meticulously monitored and adjusted to maintain peak uptake conditions.

Water temperature regulation is also essential, as it influences root oxygenation and nutrient solubility.

Implementing these advanced practices guarantees robust plant development and maximizes yield potential.

Monitoring and Maintenance

Guaranteeing the ideal performance of a hydroponic grow box necessitates meticulous monitoring and maintenance, encompassing three critical areas: nutrient solution management, light and temperature control, and regular system checks.

Accurate nutrient solution calibration and replenishment are essential to sustain plant health and growth.

Meanwhile, precise regulation of light intensity and temperature, along with systematic inspections of all system components, guarantees the environment remains conducive to optimal plant development.

Nutrient Solution Management

Effective nutrient solution management in a hydroponic system involves meticulous monitoring and maintenance to guarantee ideal plant growth and health. Precision in nutrient concentration, pH balance, and solution temperature is paramount.

Key steps include:

- Nutrient Concentration Analysis: Regularly measure and adjust the Electrical Conductivity (EC) to verify the best nutrient levels for different growth stages.

- pH Monitoring: Maintain a pH range of 5.5 to 6.5 to enhance nutrient uptake and prevent nutrient lockout.

- Temperature Regulation: Keep the nutrient solution between 65-75°F (18-24°C) to improve root absorption and prevent microbial growth.

- Solution Replacement: Periodically replace the nutrient solution to prevent the buildup of salts and contaminants, verifying a balanced nutrient profile.

Such precision guarantees robust plant development and maximized yield.

Light and Temperature Control

Maintaining ideal light and temperature conditions is indispensable for maximizing photosynthetic efficiency and ensuring robust plant development in a hydroponic grow box.

Precise light intensity and photoperiod control are vital; LED grow lights with adjustable spectrums are recommended for their energy efficiency and customizable wavelengths.

Temperature regulation is equally critical; best ranges typically lie between 70-75°F (21-24°C) to prevent thermal stress.

Implementing automated climate control systems can seamlessly monitor and adjust these parameters.

Additionally, integrating sensors for real-time data acquisition allows for dynamic adjustments, ensuring consistent environmental conditions.

Advanced monitoring systems can be linked to alert mechanisms, providing notifications for any deviations, thereby safeguarding plant health and promoting vigorous growth.

Regular System Checks

Consistent and meticulous system checks are paramount for the ideal performance and longevity of a hydroponic grow box setup. Precise monitoring and maintenance guarantee peak plant health and yield.

Key parameters require close attention:

- Nutrient Solution Levels: Regularly assess and replenish the nutrient solution to maintain the precise pH and electrical conductivity (EC) levels.

- Pump Functionality: Verify the operational integrity of water and air pumps to prevent system failures that could jeopardize plant health.

- Root Zone Inspection: Inspect roots for signs of disease, discoloration, or abnormal growth, guaranteeing a healthy root environment.

- Environmental Controls: Continuously monitor temperature, humidity, and CO2 levels using advanced sensors for a stable growth environment.

Adhering to these critical checks fosters a robust, high-yield hydroponic system.

Plant Selection Tips

Selecting appropriate plant species for your hydroponic grow box is essential for optimizing growth conditions and guaranteeing successful cultivation.

Prioritize crops with compact growth habits and high yield potential, such as leafy greens (e.g., lettuce, spinach), herbs (e.g., basil, cilantro), and dwarf varieties of fruiting plants (e.g., cherry tomatoes, strawberries).

Evaluate the specific light, temperature, and nutrient requirements of each species to harmonize with your system's capabilities.

Opt for cultivars known for their robust performance in controlled environments.

Additionally, consider the phenological stages and photoperiod sensitivity of selected species to synchronize growth cycles efficiently.

Employing such meticulous selection criteria will enhance resource utilization, maximize productivity, and guarantee a seamless cultivation experience within your hydroponic grow box.

Troubleshooting Common Issues

Diagnosing and resolving common issues in hydroponic systems necessitates a thorough understanding of plant physiology, nutrient dynamics, and environmental control mechanisms. For those pursuing innovation, recognizing these challenges early is vital to maintaining ideal plant health.

- Nutrient Imbalance: Symptoms such as yellowing leaves or stunted growth often indicate deficiencies or toxicities. Utilize a precise nutrient solution and monitor Electrical Conductivity (EC) levels.

- pH Fluctuations: Unstable pH levels can impair nutrient uptake. Maintain pH levels between 5.5 and 6.5 using calibrated pH meters and appropriate buffering agents.

- Root Rot: Excess moisture and lack of oxygen promote pathogenic growth. Guarantee adequate aeration and drainage within the grow medium.

- Pest Infestation: Early detection and integrated pest management strategies are fundamental for mitigating damage from insects and pathogens.

Conclusion

The implementation of a stealth hydroponic grow box offers numerous advantages, including discreet cultivation and efficient resource utilization.

An analogy can be drawn to a well-tuned orchestra; just as each instrument's perfect synchronization creates harmony, the precise alignment of container, nutrients, and monitoring systems guarantees ideal plant growth.

By adhering to the outlined steps, one can achieve a productive and concealed growth environment, akin to a hidden gem flourishing beneath an unassuming exterior.