How Much Does a Hydroponic Lettuce Garden Cost?

The cost of establishing a hydroponic lettuce garden ranges from $300 to $1,500, largely depending on the scale and complexity of the system. Grow lights alone can add $200 to $500 per unit to the initial investment, while nutrient solutions cost between $0.05 and $0.15 per gallon.

Operational expenses are influenced by electricity usage, primarily from lighting and climate control systems. Maintenance and upkeep, including nutrient management and equipment cleaning, also impact long-term costs.

Economies of scale and strategic system choices can greatly optimize financial outcomes. For a thorough understanding of these factors, additional insights will prove valuable.

Key Takeaways

- Initial hydroponic system setup costs range between $300 to $1,500, depending on scale and complexity.

- LED grow lights, essential for productivity, cost between $200 to $500 per unit.

- Nutrient solutions for hydroponic lettuce cost between $0.05 to $0.15 per gallon.

- Electricity expenses for grow lights, pumps, and climate control significantly impact ongoing operational costs.

Initial Setup Costs

Establishing a hydroponic lettuce garden requires an initial investment in equipment and materials, which typically ranges between $300 and $1,500 depending on the system's scale and complexity.

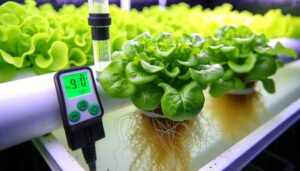

Key components include nutrient delivery systems, growth medium, water pumps, reservoirs, and pH sensors.

Cost variability arises from the choice between basic systems like Deep Water Culture (DWC) and more sophisticated setups like Nutrient Film Technique (NFT).

Analyzing the return on investment (ROI), higher upfront expenditure on advanced systems may be justified by increased yield efficiency and lower operational costs.

Additionally, economies of scale can reduce per-unit setup costs, making larger systems more economically viable.

Ultimately, the choice of system should align with specific production goals and available capital.

Grow Lights

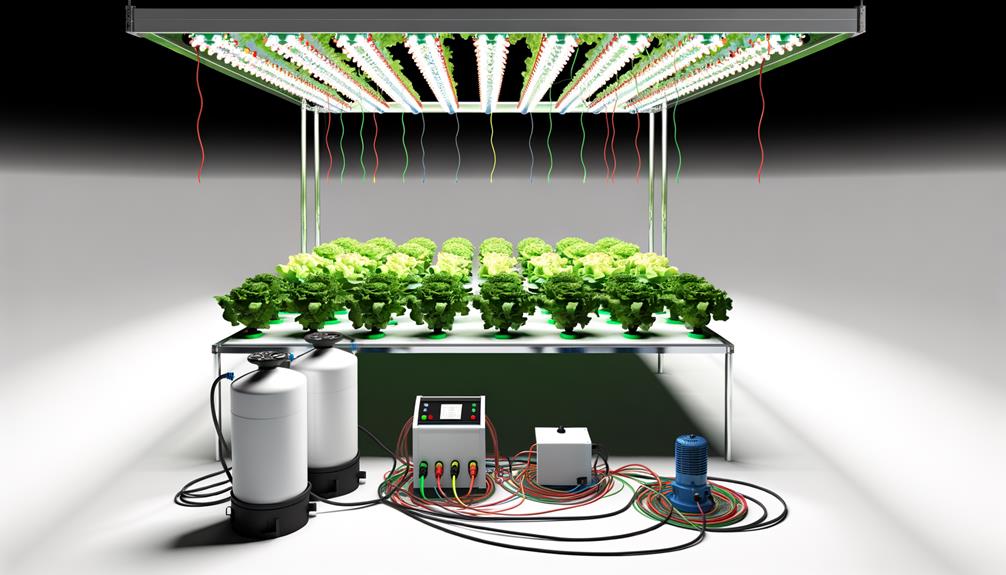

In addition to the initial setup costs, the choice and quality of grow lights greatly impact both the operational expenses and the overall productivity of a hydroponic lettuce garden.

LED grow lights, although more expensive upfront, offer significant energy savings and longer lifespans compared to traditional fluorescent or incandescent options. Data shows that LED systems can reduce electricity consumption by up to 60%, translating to lower monthly utility bills.

The initial investment in high-efficiency LEDs, averaging between $200 to $500 per unit, is offset by their durability and reduced replacement frequency. Evaluating lumens per watt and spectrum alignment with plant growth needs guarantees optimized yield.

Therefore, grow lights are a critical economic factor in hydroponic gardening.

Nutrient Solutions

Nutrient solutions play a pivotal role in the cost-efficiency and productivity of a hydroponic lettuce garden, with formulations typically ranging from $0.05 to $0.15 per gallon. These solutions, essential for ideal plant growth, can greatly impact operational costs. Economically, choosing the right blend balances nutrient quality and financial outlay, contributing to overall profitability.

Cost Savings: Lower per-gallon costs can dramatically reduce operational expenses over time.

Yield Optimization: High-quality solutions lead to faster growth cycles and larger yields.

Resource Efficiency: Precise nutrient formulations minimize waste and enhance resource utilization.

Sustainability: Environmentally friendly options can align with eco-conscious business models.

Market Competitiveness: Cost-effective nutrient management can enhance market positioning through superior product quality.

This data-driven approach underscores the importance of strategic nutrient solution investments.

Hydroponic Systems

The choice of hydroponic system greatly influences both the capital investment required and the operational efficiency of a hydroponic lettuce garden.

Systems such as Nutrient Film Technique (NFT), Deep Water Culture (DWC), and Aeroponics each present unique financial and operational profiles.

NFT systems, for example, offer lower initial costs but may require more frequent nutrient adjustments, impacting ongoing expenses.

DWC systems, while costlier upfront due to specialized tanks and air pumps, provide stable growth conditions, potentially reducing labor costs.

Aeroponics, though technologically advanced and yielding higher productivity, demands significant capital outlay and meticulous maintenance.

Economic analysis reveals that selecting the best system hinges on balancing initial investment against long-term operational efficiencies and yield potential, tailored to specific production goals.

Electricity Expenses

Operational efficiency in hydroponic systems is not only determined by the type of system employed but also greatly influenced by electricity expenses, which can constitute a substantial portion of the ongoing costs.

Accurate estimation of these costs is essential for economic viability and sustainability.

Factors contributing to electricity expenses include:

- Lighting: High-intensity grow lights can markedly drive up energy consumption.

- Pumps and Aerators: Fundamental for nutrient circulation and oxygenation, these components can run continuously.

- Climate Control: Maintaining ideal temperature and humidity levels requires energy-intensive HVAC systems.

- Automation: Advanced control systems for monitoring and adjusting conditions add to electrical usage.

Understanding these elements is vital for making informed decisions that balance cost with operational effectiveness.

Maintenance and Upkeep

Maintenance and upkeep of a hydroponic lettuce garden primarily involve the costs associated with cleaning and sterilization, as well as nutrient solution management.

Regular cleaning and sterilization are critical to prevent disease and algae growth, which can incur costs for specialized cleaning agents and labor.

Additionally, managing the nutrient solution requires consistent monitoring and replenishment, impacting both the cost and efficiency of the garden's operation.

Cleaning and Sterilization

Regular cleaning and sterilization of hydroponic systems greatly impact both the longevity of the equipment and the overall yield of the lettuce garden, thereby influencing the cost-effectiveness of the operation.

A well-maintained system reduces the risk of disease and algae buildup, which can compromise plant health and productivity.

Analytical data shows that routine cleaning can extend equipment lifespan by up to 30%, minimizing replacement costs. Additionally, consistent sterilization guarantees ideal nutrient uptake, translating into higher yields per cycle.

- Reduced disease outbreaks: healthier, more robust plants

- Extended equipment lifespan: lower capital expenditure

- Enhanced nutrient absorption: maximized yields

- Consistent performance: predictable financial returns

Economically, investing in regular maintenance yields significant long-term savings and operational efficiency.

Nutrient Solution Management

Guaranteeing the ideal composition and stability of nutrient solutions is a key factor in maximizing the economic efficiency and productivity of a hydroponic lettuce garden.

Accurate monitoring and adjustment of pH and nutrient concentration levels are essential.

Data from recent studies indicate that optimal nutrient management can reduce operational costs by up to 20%, primarily through reduced waste and enhanced growth rates.

Investment in automated nutrient dosing systems, which range from $200 to $1,000, can offer precise control and significant labor savings.

Additionally, periodic testing and calibration, costing approximately $50 monthly, maintain nutrient balance and prevent plant stress.

Consequently, a strategic approach to nutrient solution management not only sustains plant health but also maximizes financial returns for innovative growers.

Conclusion

To sum up, the cost of establishing and maintaining a hydroponic lettuce garden encompasses several factors, including initial setup, grow lights, nutrient solutions, hydroponic systems, electricity, and ongoing maintenance.

As the saying goes, 'an ounce of prevention is worth a pound of cure'; investing wisely in high-quality components can mitigate long-term expenses.

A thorough cost-benefit analysis, considering both direct and indirect costs, is essential for determining the economic viability of such an agricultural endeavor.