How Much Fertilizer Should You Use in a Hydroponic System?

In a hydroponic system, fertilizer dosage must align precisely with the plant's growth stage and type. Leafy greens typically require higher nitrogen levels, while fruiting plants benefit from increased phosphorus and potassium.

Concentrations must be tailored from germination through flowering stages—ranging from 1.2 to 3.5 mS/cm as measured by an EC meter. Correct dilution hinges on accurate water volume measurements, and pH levels should be consistently maintained between 5.5 and 6.5 to guarantee nutrient uptake.

Attention to these technical details can prevent nutrient lockout and toxicity, enhancing plant health and productivity. For a deeper exploration into precise practices, consider exploring further resources.

Key Takeaways

- Adjust fertilizer dosages based on plant growth stages: more nitrogen for leafy greens, more phosphorus and potassium for fruiting plants.

- Use high-precision EC meters to monitor and fine-tune nutrient solution strength for optimal plant growth and yield.

- Maintain pH levels between 5.5 and 6.5 to ensure efficient nutrient uptake.

- Measure and maintain consistent water volumes to prevent nutrient imbalances.

Understanding Nutrient Ratios

A fundamental aspect of optimizing fertilizer use in hydroponic systems is understanding the specific nutrient ratios required for different plant species.

Research has shown that macro-nutrients such as nitrogen (N), phosphorus (P), and potassium (K) must be tailored to the plant's growth stage to maximize yield and quality.

For instance, leafy greens typically require higher nitrogen levels to promote vigorous leaf development, while fruiting plants benefit from increased phosphorus and potassium during flowering and fruiting phases.

Employing precise nutrient formulations, supported by empirical data, enhances nutrient uptake efficiency and reduces the risk of deficiencies or toxicities.

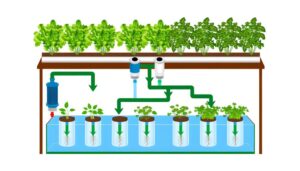

Advanced hydroponic systems leverage automated dosing technologies, which adjust nutrient solutions in real-time, ensuring ideal plant health and fostering innovation in sustainable agriculture practices.

Measuring Water Volume

Accurate determination of water volume is critical for optimizing fertilizer concentrations in a hydroponic system.

This involves precisely measuring the capacity of the reservoir and ensuring consistent volumes during refills.

Empirical methods and calibrated equipment are essential to achieve the accuracy required for effective nutrient management.

Determining Water Capacity

Determining the water capacity within a hydroponic system is essential for optimizing nutrient distribution and guaranteeing plant health. Proper water capacity ensures that plants receive adequate hydration while preventing issues like root drying or oversaturation. One key consideration is selecting the right equipment, including determining what size pump for hydroponics will provide efficient water circulation. Choosing an appropriately sized pump helps maintain a steady flow of nutrients, promoting healthy root development and overall plant growth.

Accurate assessment begins by understanding the total volume of water the system can hold, which directly influences the concentration of nutrient solutions. This involves calculating the dimensions of each reservoir, including depth, width, and length, to derive the cubic volume. For precision, use calibrated containers and make certain all measurements adhere to system specifications.

Empirical studies indicate that maintaining consistent water volume mitigates nutrient imbalances and promotes uniform growth. Additionally, integrating sensors to monitor water levels can provide real-time data, facilitating immediate adjustments.

Therefore, a meticulous approach to water capacity determination lays the foundation for an efficient, innovative hydroponic operation.

Accurate Volume Measurements

Consistently obtaining accurate volume measurements is essential for guaranteeing the precise formulation of nutrient solutions in a hydroponic system.

Employing calibrated measuring tools, such as graduated cylinders and volumetric flasks, guarantees high accuracy. For larger volumes, electronic flow meters offer precision and reliability.

Research indicates that even minor deviations in water volume can lead to significant nutrient imbalances, affecting plant health and yield (Jones, 2016). Verification of storage tank capacities and regular calibration of measurement instruments are recommended practices.

By integrating automated systems with real-time monitoring capabilities, operators can achieve superior control over nutrient solution concentrations, fostering ideal plant growth conditions.

Precision in volume measurement is not merely a recommendation but a critical component for innovative, high-efficiency hydroponic farming.

Calculating Fertilizer Dosage

Calculating the proper fertilizer dosage in a hydroponic system involves considering the nutrient solution strength, the specific growth stage of the plants, and the precise measurement of water volume.

The required concentration of nutrients changes as plants progress from germination to flowering stages, necessitating adjustments in the fertilizer mix.

Accurate water volume measurement guarantees the correct dilution, maintaining ideal nutrient levels for plant health and productivity.

Nutrient Solution Strength

The accurate measurement of fertilizer dosage in a hydroponic system is crucial for maintaining ideal nutrient solution strength and guaranteeing plant health.

Calculating the appropriate dosage begins with understanding the concentration of nutrients required, typically expressed in parts per million (ppm).

Utilizing high-precision tools like electrical conductivity (EC) meters allows growers to monitor and adjust the nutrient solution accurately.

Research indicates that best EC levels vary depending on the crop, with leafy greens thriving at lower EC (1.2-1.8 mS/cm) and fruiting plants at higher EC (2.0-3.5 mS/cm).

Regular monitoring and adjustment, informed by empirical data, guarantee nutrient availability aligns with plant needs, consequently fostering robust growth and maximizing yield potential.

Plant Growth Stage

Understanding the nutrient solution strength is foundational, but the ideal fertilizer dosage must also be adjusted according to the plant's growth stage to guarantee tailored nutrient delivery.

During the vegetative stage, plants require higher nitrogen concentrations to support robust leaf and stem development. Conversely, the flowering and fruiting stages necessitate increased levels of phosphorus and potassium to enhance reproductive structures and fruit set.

Empirical data suggests that precise nutrient adjustments at each stage optimize growth rates and yield quality. For example, a common practice involves using a nutrient solution with an N-P-K ratio of 3-1-2 during early growth, shifting to a 1-3-2 ratio during flowering.

Such stage-specific adjustments guarantee the nutrient profile aligns with the plant's physiological requirements.

Water Volume Measurement

Accurate water volume measurement is essential for determining the precise amount of fertilizer needed to maintain an ideal nutrient solution in a hydroponic system. Utilizing calibrated containers or electronic flow meters guarantees exact volume readings, mitigating the risks associated with over- or under-fertilization.

Research indicates that even minor discrepancies in water volume can greatly affect nutrient concentration (Resh, 2013). Employing volumetric calculations tailored to the specific hydroponic setup allows for the meticulous adjustment of nutrient solutions.

For innovative growers, integrating automated systems with real-time monitoring can enhance precision. These technologies provide actionable data, facilitating dynamic nutrient management and optimizing plant health.

Precise water volume measurement, consequently, serves as the cornerstone for achieving consistent, high-yield hydroponic cultivation.

Monitoring Ph Levels

Regular monitoring of pH levels is essential for maintaining ideal nutrient uptake in a hydroponic system. Best pH levels guarantee that nutrients are available in forms that plants can absorb efficiently. The recommended pH range for most hydroponic crops is between 5.5 and 6.5. Deviations from this range can lead to nutrient lockout, affecting plant health and growth. Implementing a digital pH meter or pH test strips can provide accurate readings, facilitating timely adjustments.

| Tool | Accuracy Level | Frequency of Use |

|---|---|---|

| Digital pH Meter | High | Daily |

| pH Test Strips | Moderate | Daily |

| Continuous pH Monitor | Very High | Real-Time Monitoring |

Regular monitoring mitigates risks, guaranteeing a stable and productive hydroponic environment.

Adjusting for Plant Growth Stages

Adapting nutrient concentrations in a hydroponic system to align with the specific growth stages of plants is essential for optimizing their development and yield.

Research indicates that during the vegetative stage, plants require higher levels of nitrogen to promote robust leaf and stem growth. Conversely, the flowering and fruiting stages demand elevated phosphorus and potassium levels to support bud formation and fruit set.

Precise nutrient adjustments tailored to these stages can be achieved by modifying the nutrient solution's composition. Empirical data suggests that failing to adjust nutrient profiles can lead to suboptimal growth and reduced yields.

Using EC Meters

Monitoring nutrient concentrations in hydroponic systems is essential, and the use of Electrical Conductivity (EC) meters provides an accurate and reliable method for this purpose. EC meters measure the total ionic content in the nutrient solution, offering a precise indication of fertilizer concentration.

Research indicates that ideal EC ranges vary by crop type and growth stage, necessitating regular calibration and monitoring. For instance, leafy greens typically thrive in EC levels between 1.2 to 2.0 mS/cm, while fruiting plants may require 2.0 to 3.5 mS/cm.

Utilizing EC meters enables real-time adjustments, ensuring nutrient levels remain within the desired range for optimal growth. This technology consequently facilitates data-driven decision-making, maximizing both yield and nutrient use efficiency.

Common Mistakes to Avoid

One of the most common mistakes in hydroponic systems is over-fertilization, which can lead to nutrient imbalances and plant toxicity. Precision in nutrient management is critical to optimizing plant health and yield. Miscalculations in nutrient strength can result in deficiencies or toxicities, impacting growth rates and crop quality.

| Mistake | Consequence |

|---|---|

| Over-fertilization | Nutrient imbalances, toxicity |

| Inconsistent mixing | Uneven nutrient distribution |

| Ignoring pH levels | Poor nutrient absorption |

Understanding the specific nutrient needs of your crops and regularly monitoring electrical conductivity (EC) and pH levels can mitigate these risks. Utilizing calibrated instruments guarantees accurate measurements, preventing the adverse effects of over-fertilization. Employing a systematic approach to nutrient management fosters a balanced and thriving hydroponic environment, essential for innovative agricultural practices.

Regular Maintenance Tips

Maintaining a hydroponic system requires regular monitoring of nutrient levels, pH balance, and system components to confirm ideal plant growth and yield.

Consistent analysis of the nutrient solution using an electrical conductivity (EC) meter guarantees prime concentration, preventing deficiencies or toxicities. pH levels should be checked daily with a digital pH meter, maintaining the range between 5.5 and 6.5 for most plant species.

Regularly inspect and clean pumps, tubing, and reservoirs to avoid blockages and biofilm buildup, which can impair nutrient delivery. Implementing an automated system for these tasks can enhance precision and efficiency.

Additionally, periodic recalibration of monitoring instruments is essential for accuracy, confirming data-driven adjustments that support robust plant development.

Conclusion

In sum, determining the appropriate amount of fertilizer in a hydroponic system requires careful consideration of nutrient ratios, water volume, and plant growth stages.

Regular monitoring of pH levels and electrical conductivity (EC) is essential to maintaining ideal conditions.

As the adage goes, 'an ounce of prevention is worth a pound of cure,' underscoring the importance of vigilance to avoid common mistakes.

Adhering to these principles guarantees the health and productivity of hydroponic crops.