3 Steps to Calculate the Right Hydroponic Nutrient Solution

The precise amount of hydroponic nutrient solution required depends on several factors, including plant type, growth stage, and environmental conditions. Ideal macronutrient ratios vary, commonly 3:1:2 during vegetative stages and 1:2:3 during flowering.

Monitoring Electrical Conductivity (EC) values, which range from 1.2 to 3.0 mS/cm depending on growth phase, guarantees optimal nutrient availability. Maintaining pH between 5.5 and 6.5 is critical for nutrient uptake, while regular solution replacement every 1-2 weeks prevents imbalances.

Understanding these variables and their interactions allows for tailored nutrient delivery, enhancing plant health and yield for hydroponic systems. Further exploration covers each aspect in detail.

Key Takeaways

- Seedlings require lower nutrient concentrations with an EC range of 0.8 to 1.2 mS/cm.

- Vegetative stages need higher nitrogen levels with EC values from 1.5 to 2.5 mS/cm.

- Flowering and fruiting stages demand more potassium and phosphorus, with EC between 2.0 and 3.0 mS/cm.

- Regular solution replacement every 1-2 weeks prevents nutrient depletion and pH imbalances.

Understanding Nutrient Solution Basics

At the core of hydroponic systems, the nutrient solution is a meticulously formulated mixture of essential minerals and nutrients that directly impact plant growth and health.

This solution typically includes macronutrients such as nitrogen (N), phosphorus (P), and potassium (K), alongside essential micronutrients like iron (Fe), manganese (Mn), and zinc (Zn).

Research indicates that the precise balance of these elements is vital; deviations can lead to deficiencies or toxicities, adversely affecting plant physiology.

Studies have demonstrated that ideal nutrient formulations can enhance growth rates by up to 30%, compared to traditional soil methods.

For professionals in the field, understanding the complex interactions and absorption rates of these nutrients is fundamental.

Reliable, data-driven approaches to nutrient management are indispensable for successful hydroponic cultivation.

Calculating Nutrient Concentration

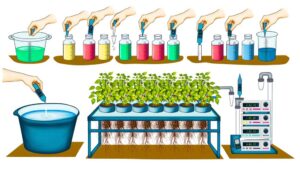

Calculating nutrient concentration in hydroponics necessitates precise determination of essential nutrient ratios and accurate measurement of the solution's strength.

Research indicates that ideal macronutrient ratios, such as nitrogen (N), phosphorus (P), and potassium (K), greatly affect plant growth and yield.

Employing tools like electrical conductivity (EC) meters and parts per million (ppm) calculations guarantees the nutrient solution maintains the required concentration for optimal plant health.

Essential Nutrient Ratios

Determining the precise ratios of essential nutrients in a hydroponic nutrient solution is crucial for maximizing plant health and yield.

Key macronutrients—nitrogen (N), phosphorus (P), and potassium (K)—must be carefully balanced, with typical ratios such as 3:1:2 during vegetative stages and 1:2:3 during flowering.

Micronutrients, including iron (Fe), manganese (Mn), and zinc (Zn), require exact concentrations, often in parts per million (ppm).

Empirical data from controlled experiments reveal that deviations from ideal ratios can lead to nutrient imbalances, manifesting as reduced growth rates or physiological disorders.

Utilizing spectrophotometry or ion chromatography for precise nutrient quantification is recommended.

Adhering to research-based guidelines guarantees the nutrient solution supports robust plant development and maximized agricultural productivity.

Measuring Solution Strength

Accurately measuring the strength of a hydroponic nutrient solution is essential to guarantee optimal nutrient availability and plant health.

The primary metric used is Electrical Conductivity (EC), which quantifies the ion concentration in the solution. Ideal EC values typically range between 1.2 to 2.5 mS/cm, varying by plant species and growth stage.

Complementary to EC, Total Dissolved Solids (TDS) provides insight into the solution's overall solute content, measured in ppm (parts per million). Regular monitoring with calibrated EC and TDS meters guarantees adherence to target nutrient concentrations.

Additionally, pH levels, ideally between 5.5 and 6.5, must be maintained to facilitate nutrient uptake.

Research indicates that precise nutrient management can enhance growth rates and yield by up to 20%.

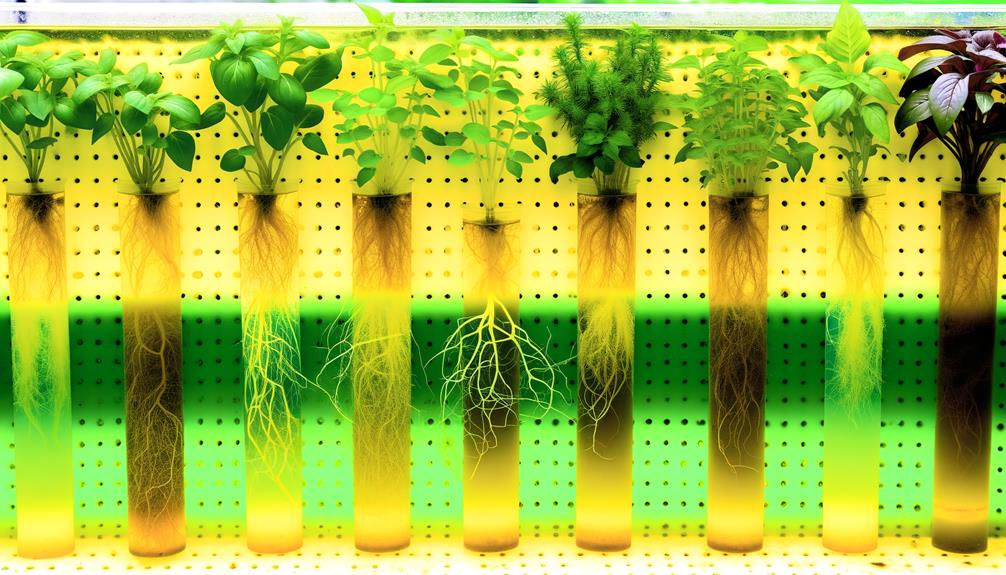

Plant Type Considerations

When determining the appropriate hydroponic nutrient solution, it is essential to take into account plant type-specific nutrient requirements, which can vary considerably between species.

Additionally, the nutrient needs of plants fluctuate across different growth stages, necessitating precise adjustments tailored to each phase.

Research indicates that crop-specific formulations enhance nutrient uptake efficiency, thereby optimizing growth and yield.

Nutrient Requirements Vary

Different plant species exhibit unique nutrient requirements that greatly impact the formulation of hydroponic nutrient solutions. Understanding these specific needs is essential for optimizing plant growth and ensuring balanced nutrient uptake in soilless systems. When comparing compost tea vs hydroponic nutrients, growers must consider factors such as nutrient availability, microbial activity, and overall plant health. While compost tea provides organic compounds and beneficial microbes, hydroponic nutrients deliver precise mineral formulations tailored for rapid absorption.

For instance, leafy greens like lettuce demand higher nitrogen concentrations to support rapid foliage growth, whereas fruiting plants such as tomatoes require elevated levels of potassium and phosphorus to enhance fruit development and root strength.

Research indicates that the ideal electrical conductivity (EC) values also vary; leafy greens thrive at 1.2-1.8 mS/cm while fruiting plants perform best at 2.0-2.5 mS/cm.

Tailoring nutrient solutions to specific plant needs is essential for maximizing yield and ensuring plant health.

Data-driven adjustments based on plant type can markedly improve nutrient uptake efficiency, thereby enhancing the overall hydroponic system performance.

Growth Stage Needs

Understanding the nutrient requirements specific to each plant type is only part of the equation; the growth stage of the plant further refines the nutrient solution formulation to optimize development and yield.

During the vegetative stage, plants generally demand higher levels of nitrogen (N) to support robust leaf and stem growth.

In contrast, the flowering or fruiting stages necessitate increased phosphorus (P) and potassium (K) to facilitate reproductive development and energy transfer.

Research indicates that precise adjustments in nutrient concentrations, such as a nitrogen-to-potassium ratio of 1:2 during the flowering phase, can markedly enhance yield and quality.

Employing data-driven approaches tailored to the plant's growth stage guarantees efficient nutrient uptake and maximizes hydroponic system productivity.

Crop-Specific Adjustments

Tailoring hydroponic nutrient solutions to the specific physiological and biochemical needs of various crops is vital for enhancing growth and maximizing yield.

For example, leafy greens like spinach and lettuce require higher concentrations of nitrogen (N) to support robust vegetative growth. Conversely, fruiting crops such as tomatoes and cucumbers benefit from elevated levels of potassium (K) and phosphorus (P) during their flowering and fruiting stages.

Research indicates that adjusting the nutrient solution's electrical conductivity (EC) and pH can meaningfully impact nutrient uptake efficiency. Studies have shown that tomatoes thrive with an EC of 2.5-3.5 mS/cm, while lettuce performs best at 1.2-1.8 mS/cm.

As a result, crop-specific adjustments are essential for attaining ideal hydroponic cultivation outcomes.

Growth Stage Requirements

The nutrient solution requirements for hydroponic systems vary considerably depending on the specific growth stage of the plants, necessitating precise adjustments to enhance nutrient uptake and promote healthy development.

During the seedling stage, plants require lower concentrations of nutrients, with electrical conductivity (EC) levels typically ranging from 0.8 to 1.2 mS/cm.

As plants shift to the vegetative phase, increased levels of nitrogen (N) are essential, with EC values rising to 1.5–2.5 mS/cm.

In the flowering and fruiting stages, higher potassium (K) and phosphorus (P) concentrations are critical, often necessitating EC values between 2.0–3.0 mS/cm.

Tailoring nutrient solutions to these developmental stages, based on empirical data, guarantees ideal growth and maximizes yield potential.

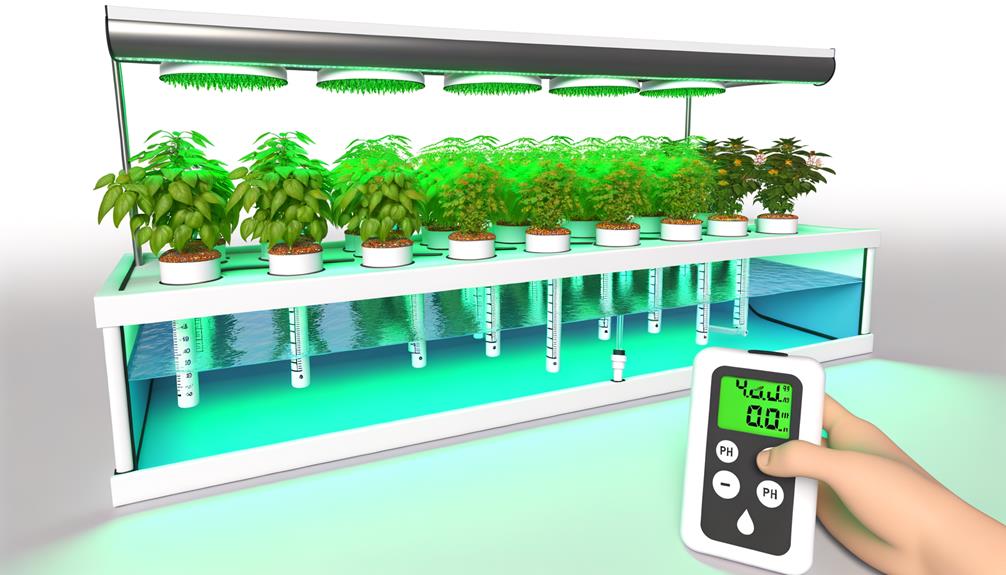

Monitoring Ph Levels

Maintaining ideal pH levels within hydroponic systems is critical for guaranteeing maximum nutrient availability and efficient plant uptake. Research indicates that pH levels between 5.5 and 6.5 enhance nutrient solubility and absorption. Regular monitoring, typically biweekly or more frequently, is essential to prevent pH fluctuations that can impede plant growth.

Key steps for effective pH monitoring include:

- Utilizing calibrated pH meters: Confirm accuracy through regular calibration.

- Recording pH readings: Maintain logs for trend analysis.

- Employing buffer solutions: Stabilize pH levels as needed.

- Testing nutrient solutions: Verify pH before and after adding nutrients.

Attention to pH guarantees peak hydroponic system performance.

Adjusting Nutrient Ratios

Precise adjustment of nutrient ratios is paramount in hydroponic systems to meet specific plant requirements and achieve excellent growth outcomes.

Nutrient formulation heavily influences plant morphology, yield, and overall health.

Utilizing elemental analysis and real-time monitoring tools such as Electrical Conductivity (EC) meters and spectrophotometers guarantees accurate nutrient delivery.

Empirical data indicates ideal Nitrogen (N), Phosphorus (P), and Potassium (K) ratios vary across plant species and growth stages.

For instance, leafy greens thrive on an N-P-K ratio of 4-1-2, while fruiting plants may require a 3-1-4 ratio.

Adjustments should be guided by growth phase-specific studies and tissue nutrient analysis, guaranteeing that plants receive macro and micronutrients in balanced proportions to mitigate deficiencies and toxicities.

Maintaining Solution Freshness

Maintaining the freshness of the hydroponic nutrient solution is vital for ideal plant growth and requires regular solution replacement to prevent nutrient depletion and pH imbalances.

Research indicates that replacing the solution every 1-2 weeks can greatly reduce the risk of pathogen accumulation and guarantee consistent nutrient availability.

Additionally, implementing stringent measures to avoid contaminants, such as using sterilized equipment and monitoring water quality, is essential to sustain a healthy hydroponic system.

Regular Solution Replacement

Regular replacement of the hydroponic nutrient solution is essential to prevent nutrient imbalances, mitigate pathogen growth, and guarantee peak plant health and productivity. Research indicates that solution replacement every 1-2 weeks is ideal, contingent on plant species and growth stage. Prolonged use of the same solution can lead to the accumulation of harmful salts and depletion of essential nutrients.

Nutrient Depletion: Essential macro and micronutrients diminish over time.

Pathogen Control: Regular replacement reduces the risk of bacterial and fungal proliferation.

pH Stability: Fresh solutions maintain consistent pH levels critical for nutrient uptake.

Oxygenation: New solutions improve dissolved oxygen levels, enhancing root respiration.

EC Monitoring: Electrical Conductivity (EC) levels remain within ideal ranges, ensuring proper nutrient availability.

Implementing a systematic replacement schedule is key to hydroponic success.

Avoid Contaminants

Guaranteeing the freshness of hydroponic nutrient solutions involves stringent measures to avoid contaminants, which can compromise plant health and yield. Contaminants such as pathogens, algae, and debris can introduce imbalances in nutrient composition and pH levels, adversely affecting plant growth.

Research indicates that utilizing sterile equipment and filtered water considerably reduces contamination risks. Regularly monitoring electrical conductivity (EC) and pH levels, supported by data from sensors, can provide early indicators of contamination.

Implementing UV sterilization and ozone treatment can further mitigate microbial presence. Additionally, replacing nutrient solutions at recommended intervals, typically every 1-2 weeks, guarantees ideal nutrient availability and minimizes contaminant buildup.

Adhering to these practices fosters a controlled environment conducive to high-yield hydroponic cultivation.

Common Mistakes to Avoid

One prevalent error in hydroponic nutrient management is the miscalculation of nutrient concentrations, leading to either nutrient toxicity or deficiency. Accurate nutrient dosing is vital to maintaining ideal plant health.

Common mistakes include:

- Improper pH Levels: The nutrient solution's pH must be within the perfect range (typically 5.5-6.5) to guarantee nutrient availability.

- Inconsistent Monitoring: Regular monitoring of Electrical Conductivity (EC) and pH levels is critical for balancing nutrient uptake.

- Overlooking Water Quality: Using water with high levels of contaminants can skew nutrient concentrations.

- Neglecting Plant Growth Stages: Nutrient needs vary across different growth phases, necessitating tailored formulations.

These errors can greatly impact hydroponic system efficiency and crop yield.

Seasonal Adjustments

Adapting hydroponic nutrient solutions to seasonal variations is essential to enhance plant growth and yield, as environmental factors such as temperature, humidity, and light intensity greatly influence nutrient uptake and metabolism.

During the winter months, reduced light intensity and lower temperatures necessitate a decrease in nutrient concentration by approximately 10-20% to prevent nutrient burn and osmotic stress.

Conversely, summer conditions often require elevated nutrient concentrations due to increased metabolic activity and transpiration rates.

Empirical studies indicate that adjusting the electrical conductivity (EC) of the solution to maintain ideal nutrient availability is vital.

Monitoring data such as daily light integral (DLI) and vapor pressure deficit (VPD) can provide actionable insights, allowing for precise adjustment of nutrient formulations to align with seasonal demands.

Tools for Measuring Solutions

Utilizing precise tools such as pH meters, electrical conductivity (EC) meters, and spectrophotometers is crucial for accurately measuring and adjusting hydroponic nutrient solutions to maximize plant health and productivity.

These instruments provide critical data that guarantee the nutrient composition remains within ideal ranges, promoting efficient nutrient uptake and robust growth.

Key tools for measuring solutions include:

- pH Meters: Essential for maintaining the correct acidity levels, guaranteeing nutrient availability.

- EC Meters: Measure the electrical conductivity to assess the nutrient concentration.

- Spectrophotometers: Analyze nutrient composition by measuring light absorption.

- TDS Meters: Total Dissolved Solids meters offer a snapshot of the overall nutrient content.

Employing these tools promotes data-driven adjustments and enhances hydroponic system performance.

Conclusion

To summarize, the precise formulation and management of hydroponic nutrient solutions are critical for ideal plant growth, akin to a well-calibrated machine operating at peak efficiency.

Variations in nutrient concentration, plant type, growth stage, pH levels, and solution freshness must be meticulously monitored and adjusted.

Avoiding common mistakes and seasonal maladjustments can greatly enhance yield.

Employing advanced measurement tools and adhering to data-driven practices guarantees a robust hydroponic system, fostering sustainable and efficient agricultural production.