7 Steps to Build a Vertical Hydroponic System at Home

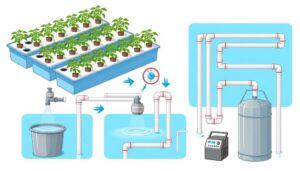

Building a vertical hydroponic system involves selecting a suitable location with adequate light and stable temperature. Gather essential materials such as robust PVC pipes for the framework, a reliable submersible pump, and efficient grow lights.

Accurate measurements and a sturdy frame are essential for stability. Install the water system with a properly sized pump and secure tubing.

Choose high-quality nutrient solutions, prepare them precisely, and monitor parameters like pH and electrical conductivity. Plant seeds in sterile mediums and guarantee proper spacing.

Regular inspections and maintenance are critical for peak performance. More detailed steps and tips can enhance understanding and execution.

Key Takeaways

- Select Location: Choose a well-lit, temperature-controlled area with good air circulation and structural support.

- Gather Materials: Collect essential tools, high-quality PVC pipes, submersible pump, LED grow lights, and monitoring equipment.

- Build Frame: Construct a stable, modular frame using durable, corrosion-resistant materials.

- Install Water System: Set up a submersible pump, main reservoir, and leak-proof tubing with an automated irrigation timer.

Understanding Vertical Hydroponics

Vertical hydroponics is a method of growing plants in vertically stacked layers without the use of soil, utilizing nutrient-rich water solutions to deliver essential nutrients directly to the plant roots.

This innovative approach maximizes space efficiency, making it ideal for urban environments and small-scale farming. The system employs a closed-loop mechanism to recirculate water, thereby minimizing waste and enhancing resource use.

Key components include vertical grow towers, a nutrient reservoir, and a pump for water circulation. Sensors and automation can be integrated to monitor pH and nutrient levels, ensuring favorable growing conditions.

This precision agriculture technique offers increased yield per square foot and requires less water compared to traditional soil-based methods, presenting a sustainable solution for modern agriculture.

Choosing the Right Location

Selecting an ideal location for your vertical hydroponic system is vital for maximizing efficiency and crop yield. Key factors include light exposure, temperature control, and space utilization. Adequate light exposure ensures optimal photosynthesis, which is essential for healthy plant growth. Maintaining proper temperature control helps prevent stress on plants, leading to higher productivity. When choosing the best types of plants for vertical hydroponics, consider leafy greens, herbs, and strawberries, as they thrive in such systems.

Best light exposure, preferably natural sunlight, should be assessed to confirm uniform distribution across all vertical tiers. A stable temperature between 65-75°F (18-24°C) is critical for plant health, necessitating possible climate control measures.

Additionally, the chosen location should facilitate ease of access for maintenance and harvesting while allowing for adequate air circulation to prevent mold and pest infestations.

Evaluate the structural integrity of the space to support the vertical framework, considering both weight and water load. Prioritize proximity to a reliable water source and electrical outlets for system components.

Gathering Necessary Materials

To guarantee the successful construction of your vertical hydroponic system, it is imperative to gather the essential tools and high-quality supplies required for the project.

This includes not only the structural components and hydroponic equipment but also the necessary nutrients and growing mediums.

Additionally, careful budgeting for these materials will help manage costs effectively while maintaining the integrity of the system.

Essential Tools Required

A thorough vertical hydroponic system requires specific tools and materials to guarantee efficient construction and ideal functionality.

Essential tools include a power drill and an assortment of drill bits, necessary for creating precise holes in PVC pipes or other structural components.

A tape measure and level facilitate accurate measurements and alignment, which are critical for maintaining system balance and water flow.

PVC cutters or a hacksaw will be required to cut pipes to the desired lengths.

Additionally, pliers and wrenches are indispensable for securing fittings and connectors.

For electrical components, wire strippers and a multimeter are essential.

Choosing Quality Supplies

Once the necessary tools are at hand, the next step involves procuring high-quality materials to guarantee the durability and efficiency of your vertical hydroponic system.

Begin with selecting robust, food-grade PVC pipes for constructing the framework, making certain they can withstand prolonged exposure to water and nutrients.

Opt for a reliable submersible pump with a flow rate suitable for your system's scale, as consistency in water circulation is paramount.

High-efficiency LED grow lights are essential to provide the ideal light spectrum for plant growth.

Additionally, choose a pH and EC meter to monitor nutrient solution parameters accurately.

Finally, utilize net pots and a high-quality grow medium like expanded clay pebbles to support plant roots effectively.

Prioritizing quality in these materials guarantees a resilient and productive hydroponic system.

Budgeting for Materials

Establishing a thorough budget is essential to guarantee all necessary materials for your vertical hydroponic system are acquired without compromising on quality or functionality.

Begin by itemizing core components such as grow lights, nutrient solutions, pumps, and grow media. Allocate funds for durable structures and reliable plumbing components to guarantee longevity and efficiency.

Consider the cost-benefit ratio of advanced technologies like automated monitoring systems, which can enhance productivity. Research market prices, compare suppliers, and seek bulk purchase discounts.

Additionally, factor in potential maintenance costs and contingencies for unforeseen expenditures. An accurately planned budget not only streamlines the acquisition process but also guarantees the system operates at peak capacity, fostering innovation and sustainable growth.

Building the Frame

Constructing the frame for a vertical hydroponic system requires precise measurements and durable materials to confirm stability and longevity. Begin by selecting high-quality materials such as treated lumber, PVC pipes, or metal tubing. These materials ascertain the frame withstands the weight and moisture inherent in hydroponic systems. Accurate measurements are critical; use a level and measuring tape to guarantee all components align perfectly.

Key considerations include:

- Stability: Confirming the frame can support the weight of growing plants and water reservoirs.

- Durability: Choosing materials resistant to corrosion and rot.

These factors are essential to crafting a robust frame that supports innovative and sustainable vertical gardening.

Setting Up the Water System

To guarantee ideal nutrient delivery and plant growth, the water system for a vertical hydroponic setup must be meticulously designed and implemented.

Begin by selecting a submersible pump with sufficient capacity to circulate water through the entire vertical structure. Confirm the pump is compatible with your chosen nutrient solution and provides consistent flow rates.

Install a main reservoir at the base, equipped with an efficient aeration system to maintain oxygen levels. Utilize PVC or flexible tubing to connect the pump to individual grow columns, confirming leak-proof seals.

Integrate a timer to automate the irrigation schedule, optimizing water use and nutrient delivery. Regularly monitor pH and EC levels using digital meters to maintain ideal growing conditions.

Installing Grow Lights

Installing grow lights in a vertical hydroponic system requires careful consideration of light type selection, ideal positioning for even coverage, and precise timing to simulate natural light cycles.

LED, fluorescent, and high-intensity discharge lights each offer distinct advantages depending on plant requirements and energy efficiency.

Ensuring that the lights are correctly positioned and operated on consistent schedules is essential for promoting healthy plant growth and maximizing yield.

Choosing Appropriate Light Types

Selecting the appropriate light types for your vertical hydroponic system is essential to guarantee peak plant growth and yield. Different light types offer varying spectra, intensities, and efficiencies, each influencing photosynthesis and growth differently.

Light Emitting Diodes (LEDs) are widely favored for their energy efficiency and customizable spectrum. High-Pressure Sodium (HPS) lights are known for their intense output, suitable for flowering stages. Fluorescent lights, while less intense, are cost-effective for seedlings and leafy greens.

- Energy Efficiency: LEDs reduce operational costs and heat output.

- Spectral Customization: Tailor light spectra to specific growth phases.

Choosing the right light type guarantees your hydroponic system operates at ideal performance, fostering innovation and sustainability in urban agriculture.

Positioning for Optimal Coverage

Achieving ideal light coverage in a vertical hydroponic system involves strategically positioning grow lights to guarantee uniform illumination across all plant tiers.

Begin by evaluating the light intensity and distribution needs of your specific plant species. Utilize adjustable light fixtures that can be repositioned to maintain consistent light exposure as plants grow.

Install lights at equidistant intervals to avoid shadows and guarantee even growth. Reflective materials on walls can enhance light efficiency by redirecting stray photons back onto the plants.

Employing a combination of overhead and side lighting can further enhance coverage, accommodating the vertical arrangement.

Light Timing and Cycles

To maximize the benefits of ideal light coverage, it is imperative to synchronize light timing and cycles with the natural photoperiod requirements of the plants. Achieving this involves meticulous planning and execution.

Specific timing of light exposure can greatly influence plant growth dynamics, optimizing photosynthesis and energy efficiency. Key considerations include:

- Maintaining a consistent light schedule to mimic natural daylight cycles, enhancing growth.

- Adjusting light intensity to suit the developmental stages of plants, ensuring robust health.

This technical approach not only maximizes plant productivity but fosters an innovative hydroponic environment.

Adding Nutrient Solution

Properly adding the nutrient solution is essential for guaranteeing the ideal growth and health of your plants in a vertical hydroponic system. Begin by selecting a high-quality nutrient mix tailored for your specific plant species. Accurately measure and mix the solution according to the manufacturer's instructions. Monitoring pH levels is critical; aim for a range between 5.5 and 6.5. Use a calibrated pH meter for precision. Regularly check and adjust the nutrient concentration using an EC meter.

| Parameter | Ideal Range |

|---|---|

| pH Level | 5.5 – 6.5 |

| EC (Electrical Conductivity) | 1.2 – 2.4 mS/cm |

| Temperature | 65°F – 75°F |

| Oxygen Levels | 5 – 8 mg/L |

| Nutrient Replenishment Frequency | Every 1-2 weeks |

Maintaining these parameters guarantees optimal nutrient uptake and robust plant growth.

Planting Your Seeds

With the nutrient solution prepared and parameters set, the next step involves strategically planting your seeds to guarantee optimal germination and growth within the vertical hydroponic system.

Select high-quality seeds and plant them in a sterile growing medium such as rockwool or coco coir, guaranteeing even spacing to prevent overcrowding. Maintain ideal moisture levels by lightly misting the seeds until germination occurs.

Consider these critical factors to enhance success:

- Seed Selection: Choose varieties known for strong performance in hydroponic systems.

- Spacing: Ensure each seed has adequate space, preventing competition for nutrients and light.

These steps will lay the foundation for robust plant development.

Maintaining Your System

Effective maintenance of your vertical hydroponic system guarantees longevity and maximizes plant health and yield.

Regularly monitor nutrient solution levels, confirming ideal pH (5.5-6.5) and electrical conductivity (1.0-3.0 mS/cm).

Inspect pump functionality and tubing integrity to avoid blockages or leaks.

Implement a bi-weekly cleaning schedule using a mild hydrogen peroxide solution to prevent algae and pathogen buildup.

Check plant roots for signs of disease or nutrient deficiencies; symptoms may include discoloration or stunted growth.

Employ integrated pest management (IPM) strategies to control pests without harmful chemicals.

Calibrate sensors monthly to maintain accurate environmental readings.

Finally, replace grow lights per manufacturer recommendations to confirm consistent light quality.

Adherence to these protocols fosters a robust and productive hydroponic environment.

Conclusion

In summary, erecting a vertical hydroponic system requires meticulous planning and execution, akin to constructing a finely-tuned instrument.

Each step—selecting an ideal location, acquiring essential materials, fabricating the frame, establishing the water system, installing grow lights, incorporating nutrient solutions, and planting seeds—constitutes a crucial note in this symphony of sustainable agriculture.

The resultant harmony of efficient growth and resource conservation underscores vertical hydroponics as a beacon of modern agricultural innovation.

The system's maintenance guarantees continuous, flourishing yields.