10 Steps to Treat Tap Water for Hydroponic Success

Treating tap water for hydroponics requires ensuring ideal pH levels (5.5 to 6.5), maintaining optimal electrical conductivity (1.2-2.0 mS/cm), and eliminating contaminants like heavy metals, chlorine, and chloramine. Begin by using RO (reverse osmosis) systems or deionization to remove impurities.

Activated carbon filters can effectively eliminate chlorine and chloramine, while dechlorinating agents offer quick solutions for removing these disinfectants. Regular pH and EC testing are crucial, and adjustments can be made using appropriate hydroponic solutions.

For consistent nutrient uptake and plant health, it is important to monitor water conditions continuously. Explore these methods further for a robust hydroponic setup.

Key Takeaways

- Test Water Quality: Regularly test for pH, EC, heavy metals, chlorine, and other contaminants using digital meters and specialized kits.

- Use Activated Carbon Filters: Install activated carbon filters to remove chlorine, chloramine, and organic contaminants effectively.

- Employ Reverse Osmosis: Utilize reverse osmosis systems to eliminate up to 99% of contaminants, including heavy metals and dissolved salts.

- Adjust pH Levels: Continuously monitor and adjust pH to maintain the ideal range of 5.5 to 6.5 using pH up or pH down solutions.

Understanding Water Quality

Understanding water quality is vital for hydroponic systems, as it directly impacts nutrient availability and plant health. Ideal water quality guarantees that plants receive the precise balance of nutrients required for robust growth.

Parameters such as pH, electrical conductivity (EC), and total dissolved solids (TDS) must be meticulously monitored and adjusted. Maintaining a pH range between 5.5 and 6.5 is essential for nutrient absorption. EC levels, indicative of nutrient concentration, should align with plant-specific needs, typically between 1.2 and 2.0 mS/cm.

Regular testing and adjustments prevent nutrient lockout and deficiency, fostering an environment conducive to innovation in plant cultivation. Employing reverse osmosis or deionization systems can greatly enhance water quality, promoting superior hydroponic outcomes.

Identifying Common Contaminants

When preparing tap water for hydroponic use, it is essential to identify common contaminants that can impair plant growth.

Heavy metals, such as lead and cadmium, may be present and can be toxic to plants even at low concentrations.

Additionally, chlorine and chloramine are often used in municipal water supplies to disinfect.

Variations in pH levels can affect nutrient availability and uptake.

Heavy Metals Presence

Identifying the presence of heavy metals in tap water is vital for hydroponic systems, as contaminants like lead, mercury, and cadmium can hinder plant growth and pose health risks.

Utilize water testing kits specifically designed for heavy metals to assess tap water quality. These kits provide precise readings, enabling you to detect even trace amounts.

Should contamination be confirmed, employ reverse osmosis (RO) systems or specialized heavy metal filters to purify the water. RO systems are highly effective, removing up to 99% of contaminants.

Regular monitoring is important; periodic tests guarantee ongoing water quality, safeguarding both plant health and yield.

Chlorine and Chloramine

In addition to heavy metals, chlorine and chloramine are common contaminants in tap water that can negatively affect hydroponic systems. These disinfectants can disrupt nutrient uptake and harm beneficial microbial life.

To effectively treat tap water, consider the following methods:

- Activated Carbon Filtration: Employ activated carbon filters to remove chlorine and chloramine, ensuring cleaner water for plant roots.

- Chemical Neutralization: Utilize chemical agents like sodium thiosulfate to neutralize chlorine and chloramine, preserving the solution's integrity.

- Aeration: Aerate the water by vigorously agitating it for 24-48 hours, which helps dissipate chlorine, though less effective for chloramine.

- Reverse Osmosis: Implement a reverse osmosis system to eliminate nearly all contaminants, providing a purified water source for hydroponics.

These strategies promote healthier plant growth by mitigating the adverse effects of chlorine and chloramine.

Ph Level Variations

Maintaining ideal pH levels is crucial in hydroponics, as fluctuations can indicate the presence of common contaminants such as heavy metals, organic compounds, and dissolved salts.

Heavy metals like lead and copper can disrupt nutrient uptake, while organic compounds might foster microbial growth, impairing plant health. Dissolved salts, particularly calcium and magnesium, can elevate pH, leading to nutrient lockout.

Regularly monitoring pH with a reliable digital meter guarantees rapid detection of deviations. Implementing activated carbon filters can effectively reduce organic contaminants, while ion exchange resins can target specific heavy metals.

Adjusting pH with dedicated hydroponic solutions, such as pH up or pH down products, offers precise control. Consistent vigilance and corrective measures maintain ideal conditions for plant growth and innovation in hydroponic systems.

Testing Your Tap Water

Ensuring the quality of your tap water for hydroponics begins with conducting thorough tests to measure its pH levels, electrical conductivity (EC), and potential contaminants. Testing hydroponic water quality helps determine if any adjustments are necessary to optimize nutrient absorption for plant growth. If pH levels are too high or low, adding buffering solutions can help maintain the ideal range. Regular monitoring also ensures that contaminants such as chlorine or heavy metals do not negatively impact plant health.

Accurate testing will help you identify any adjustments needed to enhance plant growth. Follow these steps to test your tap water effectively:

- pH Testing: Use a digital pH meter to measure the acidity or alkalinity of your water. The ideal pH range for hydroponics is typically between 5.5 and 6.5.

- EC Measurement: Employ an EC meter to gauge the total dissolved salts, ensuring the nutrient solution is within the best range of 1.2 to 2.0 mS/cm.

- Contaminant Screening: Test for common impurities like chlorine, chloramine, and heavy metals using specialized testing kits.

- Water Sample Analysis: Send a sample to a laboratory for a detailed mineral profile.

Using Activated Carbon Filters

Activated carbon filters are highly effective in removing chlorine, chloramine, and various organic contaminants from tap water, making them an essential tool for hydroponic systems.

These filters operate by adsorbing impurities onto the surface of activated carbon granules, which possess a high surface area due to their porous structure.

For ideal performance, it is vital to regularly replace the activated carbon media, as its adsorption capacity diminishes over time.

When selecting a filter, consider the flow rate and the volume of water your hydroponic system requires.

Inline filters are advantageous for continuous filtration, ensuring a consistent supply of purified water.

Employing Reverse Osmosis

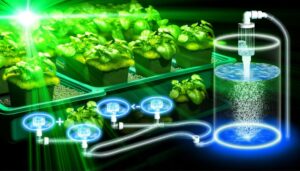

While activated carbon filters are effective in removing many contaminants, reverse osmosis (RO) systems provide a more thorough purification by eliminating a broader range of impurities, including dissolved solids, heavy metals, and microorganisms.

Implementing an RO system in your hydroponic setup involves several critical steps:

- Pre-filtration: An initial sediment filter removes larger particles, protecting the RO membrane from clogging.

- RO Membrane: This semi-permeable barrier allows only pure water to pass, effectively filtering out up to 99% of contaminants.

- Post-filtration: An activated carbon filter further polishes the water, removing any remaining organic compounds.

- Storage: Treated water is typically stored in a pressurized tank, guaranteeing a consistent supply for your hydroponic system.

This multi-stage process guarantees ideal water quality, essential for maximizing plant growth and health.

Dechlorinating Tap Water

Dechlorinating tap water is essential for maintaining a healthy hydroponic system, as chlorine can be harmful to plants.

One common method is letting the water sit for 24-48 hours to allow chlorine to naturally dissipate.

Alternatively, dechlorinating agents or carbon filtration systems can be employed for quicker and more efficient removal of chlorine.

Let Water Sit

Allowing tap water to sit uncovered for 24 to 48 hours is an effective method to dechlorinate it for hydroponic use. This simple yet efficient process enables chlorine, a common disinfectant, to dissipate naturally, safeguarding plant health.

To maximize dechlorination, follow these steps:

- Select a Container: Choose a non-reactive, wide-mouthed container to increase the water's exposure to air.

- Fill and Place: Fill the container with tap water and place it in a well-ventilated area, avoiding direct sunlight to prevent algae growth.

- Monitor Time: Allow the water to sit undisturbed for at least 24 hours, extending to 48 hours for best results.

- Check for Chlorine: Use chlorine test strips to confirm the absence of chlorine before introducing the water to your hydroponic system.

This method guarantees your plants thrive without exposure to harmful chlorine.

Use Dechlorinating Agents

For a more rapid and reliable method of removing chlorine from tap water, using dechlorinating agents can be highly effective. These agents, often available in liquid or tablet form, chemically neutralize chlorine and chloramine, making the water safe for hydroponic systems.

When selecting a dechlorinating agent, make certain it is specifically formulated for hydroponic use to avoid any potential contaminants. The dosage typically depends on the volume of water and concentration of chlorine present; always adhere to manufacturer instructions for precise application.

Implementing these agents provides immediate results, allowing growers to quickly prepare water without extensive waiting periods. This method is particularly advantageous for large-scale operations or those requiring a consistent water supply, enhancing overall system efficiency.

Carbon Filtration Method

Another effective method for removing chlorine and chloramine from tap water in hydroponic systems is the use of carbon filtration, which involves passing the water through activated carbon to adsorb these chemicals.

This method is advantageous due to its efficiency and ease of implementation.

The steps to set up a carbon filtration system are as follows:

- Select an Activated Carbon Filter: Choose a filter specifically designed for water treatment, verifying it has a high adsorption capacity.

- Install the Filter: Connect the filter to your water supply line, following the manufacturer's instructions.

- Flush the System: Run water through the filter to remove any initial carbon dust and guarantee peak performance.

- Monitor and Replace: Regularly check the filter's condition and replace it as per the manufacturer's guidelines to maintain efficacy.

Balancing Ph Levels

Balancing pH levels in hydroponic systems is vital for nutrient uptake and overall plant health. Ideal pH levels typically range between 5.5 and 6.5, ensuring that nutrients remain soluble and accessible to plant roots.

Begin by testing the pH of your treated tap water using a reliable pH meter. If adjustments are necessary, employ pH up or pH down solutions, carefully adding small amounts and retesting until the desired range is achieved.

Continuous monitoring is essential; fluctuations can lead to nutrient lockout or toxicity. Implement automated pH controllers for precision and consistency.

Maintaining stable pH levels not only enhances nutrient absorption but also fosters a robust and resilient hydroponic system, driving innovative agricultural practices forward.

Adding Essential Minerals

Incorporating essential minerals into your hydroponic system is critical to guarantee optimal plant growth and development. Hydroponic plants rely on a carefully balanced nutrient solution to thrive.

To secure ideal results, consider the following essential minerals:

- Nitrogen (N): Important for leaf and stem growth, nitrogen supports photosynthesis and overall plant vigor.

- Phosphorus (P): Essential for root development and flowering, phosphorus aids in energy transfer within the plant.

- Potassium (K): Key for water regulation and enzyme activation, potassium enhances fruit quality and disease resistance.

- Calcium (Ca): Important for cell wall structure and stability, calcium prevents common issues like blossom end rot.

Adding these minerals in precise proportions will foster robust plant health and maximize your hydroponic system's productivity.

Monitoring Water Conditions

To guarantee the added minerals are effectively utilized by your hydroponic plants, it is imperative to consistently monitor water conditions such as pH, electrical conductivity (EC), and temperature.

Maintaining a pH range of 5.5 to 6.5 secures optimal nutrient availability. Utilize a high-precision pH meter for accuracy.

Electrical conductivity should be regularly checked with an EC meter, keeping values between 1.2 to 2.0 mS/cm for most plants to prevent nutrient lockout or deficiency.

Temperature control is essential; water temperatures between 18°C and 24°C (64°F to 75°F) promote root health and nutrient uptake. Employ digital thermometers and automated environmental controls for precision.

Regularly calibrate your instruments to guarantee accurate readings and adapt to changing conditions swiftly.

Conclusion

Treating tap water for hydroponics guarantees ideal plant growth by addressing contaminants, pH balance, and essential mineral content.

Despite concerns about the complexity and cost of water treatment methods like reverse osmosis and activated carbon filtration, the benefits—such as improved nutrient absorption and healthier plants—outweigh the initial investment.

By meticulously monitoring water quality and making necessary adjustments, growers can create a thriving hydroponic system that maximizes yield and sustainability.