What Is Hydroponic Fodder System

A hydroponic fodder system is an advanced agricultural method that grows fodder crops using nutrient-rich water solutions, eliminating the need for soil. This technique accelerates plant growth, making fodder ready within 7 days and uses up to 90% less water compared to traditional farming.

Key components include germination trays, nutrient delivery systems, and environmental control units, which guarantee ideal growth conditions. The controlled environment enhances nutrient absorption, improves feed conversion, and reduces disease risks.

By adopting these systems, farmers can improve livestock health and productivity while securing sustainability. For deeper insights into its implementation and benefits, further exploration is recommended.

Key Takeaways

- Hydroponic fodder systems use nutrient-rich water solutions instead of soil for plant growth.

- Seeds germinate in controlled trays, growing up to 50% faster than traditional methods.

- These systems use up to 90% less water compared to conventional agriculture.

- Environmental control units regulate temperature and humidity for optimal plant health.

How It Works

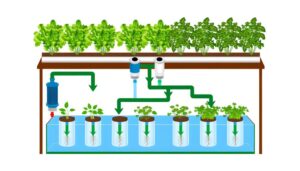

A hydroponic fodder system operates through the utilization of nutrient-rich water solutions to cultivate plant growth without the need for soil.

This cutting-edge agricultural technique involves germinating seeds in a controlled environment, where they are placed on trays and periodically irrigated with a precisely balanced nutrient solution.

The absence of soil reduces the risk of diseases and pests, enhancing crop health.

Research indicates that hydroponically grown fodder can achieve a growth rate 50% faster than traditional methods, producing a highly nutritious feed in as little as 7 days.

Additionally, this system can utilize up to 90% less water compared to conventional soil-based agriculture, making it an eco-friendly and efficient option for sustainable livestock feeding.

Key Components

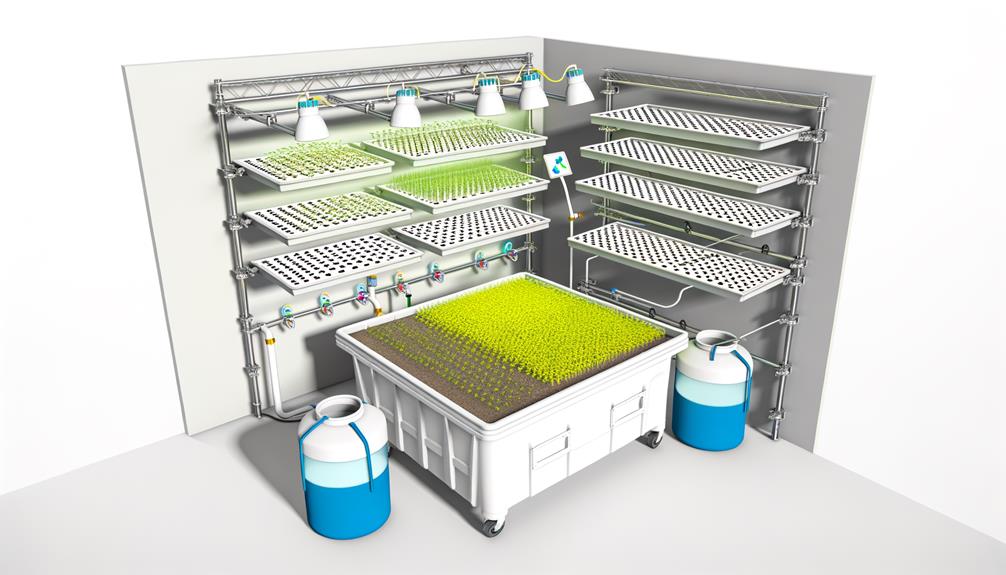

Integral to the functionality of a hydroponic fodder system, key components include germination trays, nutrient delivery systems, water reservoirs, and environmental control units.

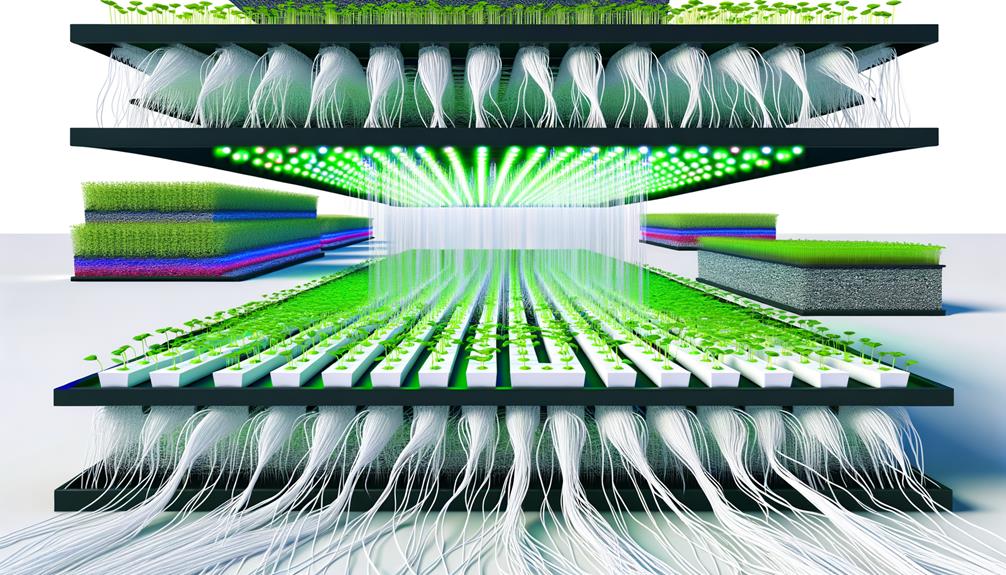

Germination trays provide a structured environment for seed sprouting, maximizing space efficiency.

Nutrient delivery systems guarantee that essential minerals are consistently available, enhancing plant growth and health.

Water reservoirs maintain a steady supply of hydration, vital for the continuous operation of the system.

Environmental control units, encompassing temperature and humidity regulators, facilitate optimal growing conditions, negating external climate fluctuations.

Advanced implementations may also integrate automated monitoring systems, offering real-time data analytics to fine-tune growth parameters.

These components collectively create a controlled, efficient, and scalable solution for producing high-quality fodder.

Benefits

The hydroponic fodder system offers several significant advantages, including enhanced nutrient absorption, reduced water usage, and improved livestock health.

Research indicates that hydroponically grown fodder can increase nutrient bioavailability, leading to more efficient feed conversion.

Furthermore, this system demonstrates up to 90% less water consumption compared to traditional soil-based farming, while also contributing to the overall health and productivity of livestock through a more nutrient-dense diet.

Enhances Nutrient Absorption

How does a hydroponic fodder system facilitate ideal nutrient absorption in livestock?

Hydroponic fodder systems offer a controlled environment that optimizes the bioavailability of essential nutrients.

Research indicates that hydroponically grown fodder, such as barley, contains higher concentrations of vitamins, minerals, and amino acids compared to conventional feed.

This elevated nutrient profile enhances the digestibility and absorption rates in livestock, resulting in improved animal health and productivity.

For instance, a study by Dung et al. (2010) demonstrated a 20% increase in feed conversion efficiency.

In addition, the absence of soil reduces the risk of pathogen contamination, ensuring cleaner and safer fodder.

Consequently, hydroponic systems present a scientifically validated, innovative approach to boosting nutrient absorption in modern agricultural practices.

Reduces Water Usage

Hydroponic fodder systems considerably reduce water usage by utilizing closed-loop irrigation techniques that recycle water efficiently.

Research indicates that traditional soil-based fodder production can require up to 98% more water compared to hydroponic methods.

These systems operate on principles of sustainability, capturing and reusing water through a series of filtration and recirculation processes.

Data from recent studies show that hydroponic fodder production typically requires only 2-3 liters of water per kilogram of fodder, as opposed to the 70-80 liters needed in conventional farming.

This reduction not only conserves a critical resource but also mitigates the environmental footprint of agricultural practices.

For innovators in agritech, such systems present a viable solution to the growing concerns of water scarcity.

Boosts Livestock Health

Consistently, hydroponic fodder systems have demonstrated significant benefits in boosting livestock health through enhanced nutritional profiles and reduced exposure to pathogens.

Research indicates that hydroponically grown fodder typically contains higher levels of essential nutrients, such as vitamins A, E, and C, as well as increased enzyme activity. These nutritional enhancements contribute to improved immune function and overall wellness in livestock.

Additionally, the controlled environment of hydroponic systems minimizes the risk of contamination from soil-borne pathogens and mycotoxins, leading to lower incidences of disease.

Data from various studies corroborate that livestock consuming hydroponic fodder exhibit higher growth rates, better feed conversion ratios, and reduced veterinary costs.

This innovative approach offers a sustainable solution for advancing animal health and productivity.

Types of Crops

The selection of crops for hydroponic fodder systems includes popular varieties such as barley, wheat, and oats, which are favored for their rapid growth and high yield.

Nutrient-rich options like alfalfa and clover provide additional benefits due to their superior protein and mineral content.

Understanding the growth cycle differences among these crops is essential for optimizing production schedules and ensuring consistent fodder availability.

Popular Fodder Varieties

Among the popular fodder varieties cultivated in hydroponic systems, barley, wheat, and alfalfa are particularly notable for their rapid growth rates and high nutritional value. Barley, often favored for its high germination rate, can yield up to 8 kg of fresh fodder per kg of seed. Wheat provides a well-balanced nutritional profile, making it ideal for diverse livestock. Alfalfa stands out for its protein content, essential amino acids, and vitamins.

| Fodder Type | Key Benefits |

|---|---|

| Barley | Rapid growth, high yield |

| Wheat | Balanced nutrition |

| Alfalfa | High protein, essential nutrients |

These crops are meticulously selected based on their growth efficiency and essential nutrient content, providing sustainable and efficient fodder solutions for modern farming practices.

Nutrient-Rich Options

As the demand for efficient and sustainable livestock feed intensifies, selecting nutrient-rich crops for hydroponic fodder systems becomes paramount to optimizing animal health and productivity.

Barley, commonly preferred, offers high digestibility and protein content, essential for livestock performance. Research indicates barley fodder can enhance weight gain by up to 20%.

Wheat, another viable option, provides robust energy levels due to its carbohydrate-rich profile.

Oats and sorghum also present significant benefits, including essential amino acids and fiber.

Alfalfa, renowned for its high yield, delivers important vitamins and minerals, particularly calcium and magnesium.

Significantly, these crops' nutrient densities can be fine-tuned via hydroponic techniques, supporting bespoke nutritional strategies and promoting sustainable agricultural practices.

Growth Cycle Differences

Growth cycles in hydroponic fodder systems vary considerably among different crop types, influencing harvest timelines and nutritional outcomes.

Barley, for instance, typically reaches ideal growth within six to eight days, delivering high protein and digestible fiber content.

Wheat and oats, comparably, follow similar cycles but exhibit slight variations in biomass yield and nutrient profiles.

Research from the Journal of Agricultural and Food Chemistry indicates that maize requires approximately 10 days for hydroponic cultivation, offering enhanced carbohydrate content.

Conversely, legumes like alfalfa necessitate longer periods, around 12-14 days, to achieve peak nutritional value.

These variations necessitate tailored management strategies to enhance growth conditions, thereby maximizing efficiency and nutritional output for specific livestock dietary needs.

Setup Requirements

Implementing a hydroponic fodder system necessitates a thorough understanding of essential components such as lighting, water delivery mechanisms, and nutrient solutions to optimize plant growth efficiency. Proper management of these components ensures that crops receive adequate hydration and nutrients, leading to healthier and more productive yields. A well-designed hydroponic drip system setup delivers a controlled amount of water and nutrients directly to the plant roots, reducing waste and enhancing efficiency. Moreover, maintaining optimal environmental conditions, such as temperature and humidity, further supports vigorous plant development in a hydroponic fodder system.

High-intensity LED lights are recommended to provide the necessary spectrum for photosynthesis, guaranteeing robust plant development.

Water delivery systems, such as drip irrigation or NFT (Nutrient Film Technique), assure consistent moisture and nutrient supply.

Precision in nutrient formulation is critical; hydroponic solutions must contain balanced macro and micronutrients tailored to the specific fodder crop.

Environmental control systems, including temperature and humidity management, further enhance growth conditions.

Additionally, modular shelving and automated monitoring systems can streamline operations, enabling scalable and sustainable production.

Understanding these components is crucial for maximizing yield and efficiency in hydroponic fodder systems.

Maintenance Tips

To guarantee the longevity and efficiency of a hydroponic fodder system, regular monitoring and maintenance of components such as pH levels, nutrient concentration, and system cleanliness are imperative.

Ideal pH levels should be maintained between 5.5 and 6.5 to enhance nutrient uptake. Nutrient solutions require precise calibration, with electrical conductivity (EC) ideally between 1.5 to 2.5 mS/cm for fodder growth.

Frequent system cleaning prevents biofilm formation and pathogen proliferation; a 1:100 bleach solution is effective for sanitization. Water quality should be assessed regularly—aim for low total dissolved solids (TDS) under 500 mg/L.

Implementing automated sensors and IoT devices can streamline these tasks, ensuring real-time adjustments and improved fodder yield.

Challenges and Solutions

Hydroponic fodder systems face several challenges, including the meticulous control of environmental parameters and the prevention of mold and diseases, which can greatly impact productivity and crop health.

Key challenges include maintaining ideal humidity and temperature levels, which are critical to preventing mold proliferation. According to studies, relative humidity should be kept below 70%, and temperatures should be monitored closely to avoid pathogen growth.

Additionally, nutrient imbalances can lead to compromised fodder quality.

Solutions involve employing automated climate control systems for precise monitoring and using UV sterilization or hydrogen peroxide treatments to mitigate microbial contamination.

Implementing Integrated Pest Management (IPM) strategies can further enhance system resilience, ensuring sustainable and high-yield fodder production.

Conclusion

In summary, the hydroponic fodder system represents a transformative approach to sustainable agriculture, offering numerous advantages such as resource efficiency and improved crop yield.

However, it also presents challenges that require strategic solutions.

What future innovations could further optimize this system?

By leveraging advanced technologies and research-driven methodologies, the potential for this system to revolutionize agricultural practices and contribute to global food security is immense.

Continued investment in research and development will be pivotal in revealing its full potential.