What Size Pump Do I Need for My Hydroponic System

Choosing the correct pump size for your hydroponic system involves evaluating several factors. Calculating the flow rate is essential; typically, circulating the entire system's water volume every 1-2 hours guarantees adequate nutrient and oxygen delivery.

For Ebb and Flow systems, aim for a flow rate of 50-100 GPH, while Drip systems need 1-2 GPH per plant. Consider the Total Dynamic Head (TDH), which includes vertical lift and friction losses, to prevent underperformance.

Additionally, your reservoir should adequately meet the system's weekly requirements, factoring in plant uptake and evaporation. These considerations are key to achieving efficient nutrient delivery and robust plant growth.

Key Takeaways

- Match pump flow rate (GPH) with system type; NFT and DWC need 1-2 times system volume per hour.

- Calculate Total Dynamic Head (TDH) by adding vertical lift and friction losses for effective nutrient delivery.

- Ensure reservoir volume is adequate, typically 20-30 gallons for 10 plants, to maintain stable nutrient levels.

- Choose submersible pumps for smaller systems and external pumps for larger setups with advanced performance needs.

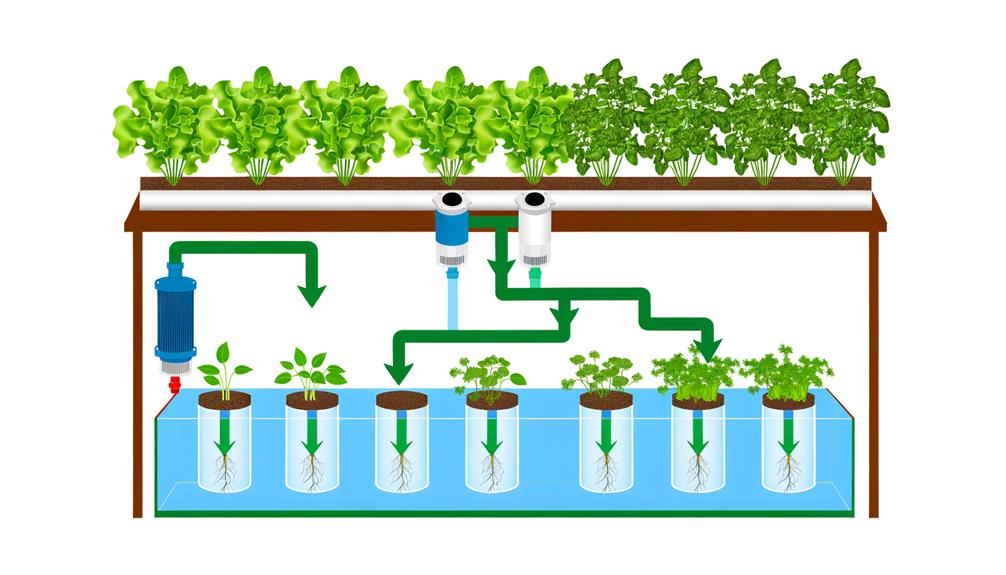

Types of Hydroponic Systems

Hydroponic systems can be broadly categorized into several types, each with unique operational principles and specific requirements for peak performance.

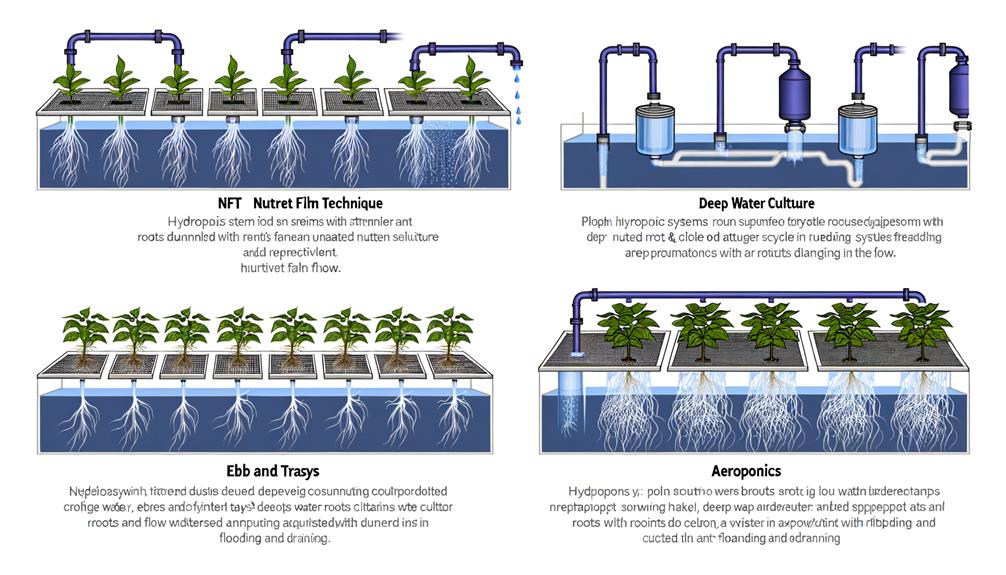

The primary types include Nutrient Film Technique (NFT), Deep Water Culture (DWC), Ebb and Flow (Flood and Drain), Aeroponics, and Drip Systems.

NFT systems utilize a thin film of nutrient solution flowing over the roots, requiring precision in pump selection for continuous flow.

DWC systems submerge roots in nutrient-rich water, necessitating robust aeration.

Ebb and Flow systems employ intermittent flooding, demanding precise timing and pump capacity.

Aeroponics suspends roots in air, misted with nutrients, consequently requiring high-pressure pumps.

Drip systems deliver nutrients directly to the root zone, necessitating consistent pump performance for ideal distribution.

Each system's efficacy hinges on tailored pump specifications.

Calculating Water Flow Rate

To determine the appropriate water flow rate for a hydroponic system, it is crucial to evaluate the specific requirements of the chosen system type and the plant species being cultivated. Different hydroponic systems, such as NFT (Nutrient Film Technique) or DWC (Deep Water Culture), demand varying flow rates to guarantee peak nutrient delivery and oxygenation. Accurate flow rate calculation involves understanding the volume of water your system holds and the rate at which it needs to be circulated. Typically, a general guideline is to circulate the entire system's water volume every 1-2 hours. The table below provides typical flow rates for common hydroponic systems:

| System Type | Recommended Flow Rate (GPH) |

|---|---|

| NFT | 1-2 times system volume/hour |

| DWC | 1-2 times system volume/hour |

| Ebb & Flow | 50-100 GPH |

| Drip | 1-2 GPH per plant |

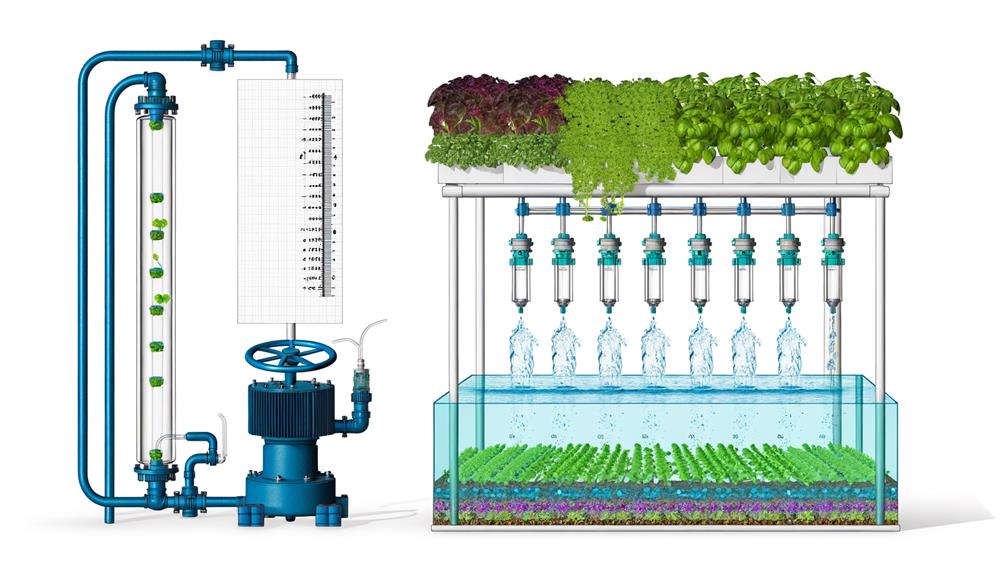

Determining Pump Head Height

Calculating the pump head height, a critical factor in hydroponic systems, involves determining the vertical distance that the pump needs to lift the nutrient solution from the reservoir to the highest point in the system.

This height, also known as total dynamic head (TDH), includes vertical lift, friction losses in tubing, and any additional resistance from fittings and valves.

Accurate measurement of pump head height guarantees ideal delivery pressure, preventing underperformance or system damage.

To calculate TDH, sum the vertical height with friction loss values derived from flow rate and pipe diameter tables.

This meticulous approach assures that the pump delivers the necessary pressure to sustain nutrient flow, thereby enhancing system efficiency and plant health.

Understanding Reservoir Volume

After determining the pump head height, the next significant factor in enhancing a hydroponic system's performance is understanding the reservoir volume required to maintain an adequate supply of nutrient solution.

Accurate reservoir volume calculation guarantees a stable nutrient environment, vital for plant health and growth. Typically, the reservoir should hold sufficient solution to last a week, accounting for plant uptake and evaporation. For instance, a system supporting 10 plants might require a 20-30 gallon reservoir.

Additionally, consider the total system volume, including tubing and grow trays, to avoid underestimating the required capacity. Maintaining a preferable reservoir volume minimizes nutrient fluctuations, promotes consistent pH levels, and enhances oxygenation, leading to more robust plant development and efficient resource utilization.

Choosing the Right Pump

Selecting the appropriate pump for your hydroponic system is vital in ensuring adequate nutrient delivery and overall system efficiency. A well-chosen pump helps maintain proper water circulation, preventing nutrient imbalances and promoting healthy root development. When looking for the best air pump for hydroponics, consider factors such as reservoir size, airflow capacity, and noise level to ensure optimal oxygenation. A reliable pump enhances plant growth by supplying roots with sufficient oxygen while keeping the nutrient solution well-aerated.

Key factors to evaluate include the pump's flow rate, measured in gallons per hour (GPH), which should align with your system's reservoir volume and plant requirements.

Additionally, the pump's head height capability is essential, as it determines the maximum height nutrients can be pushed.

Submersible pumps are ideal for smaller systems, offering quiet operation and easy installation, while external pumps are suited for larger setups, providing enhanced power and durability.

Advanced features like adjustable flow rates and energy-efficient designs can further optimize performance, ensuring your hydroponic system remains at the cutting edge of agricultural innovation.

Conclusion

Selecting the appropriate pump for a hydroponic system necessitates a thorough understanding of water flow rate, pump head height, and reservoir volume.

For instance, a 100-liter reservoir typically requires a pump that can deliver approximately 400 liters per hour to guarantee ideal nutrient circulation. This statistic underscores the importance of precise calculations in maintaining system efficiency.

With the right pump, hydroponic systems can achieve superior plant growth, reflecting the critical role of technical specifications in agricultural innovation.